Vessel with submersible hulls

a technology of submerged vessels and hulls, which is applied in the direction of floating buildings, bulkheads/piles, vessel construction, etc., can solve the problems of difficult extrapolation to higher, weak limit in size of mono-hull vessels, and inability to perform o&m operations on production platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

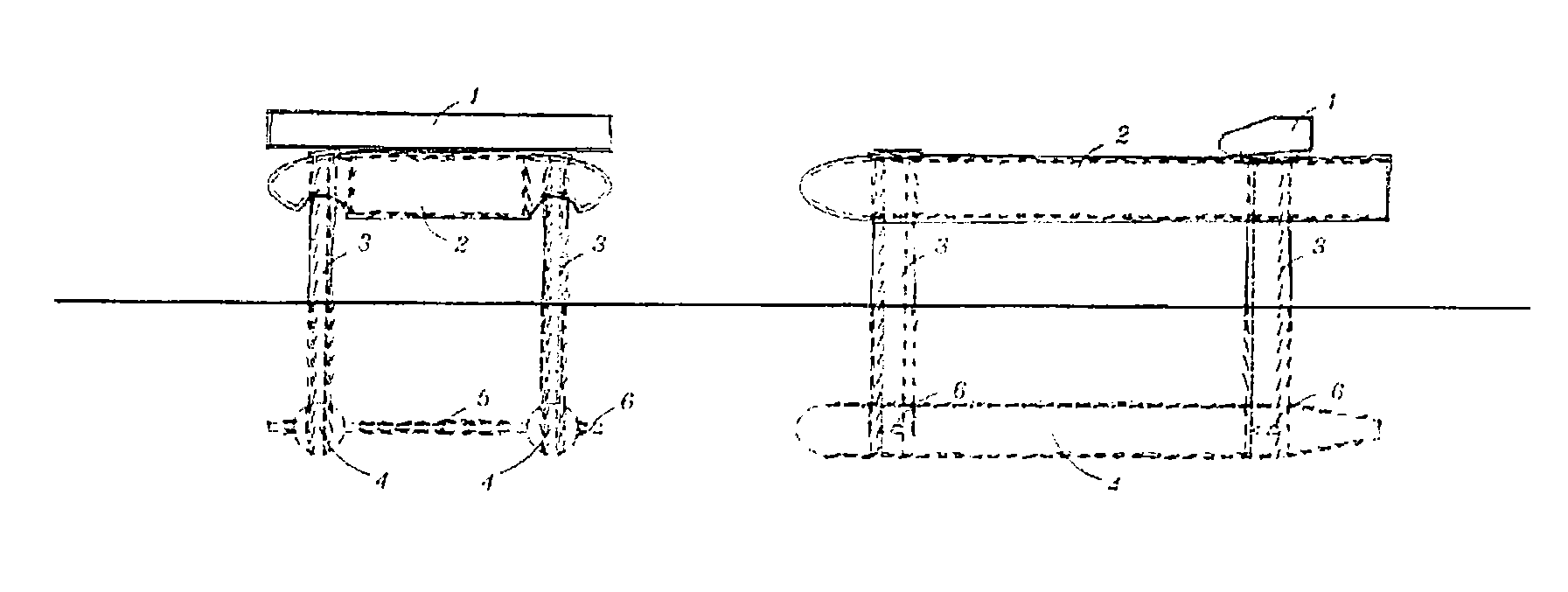

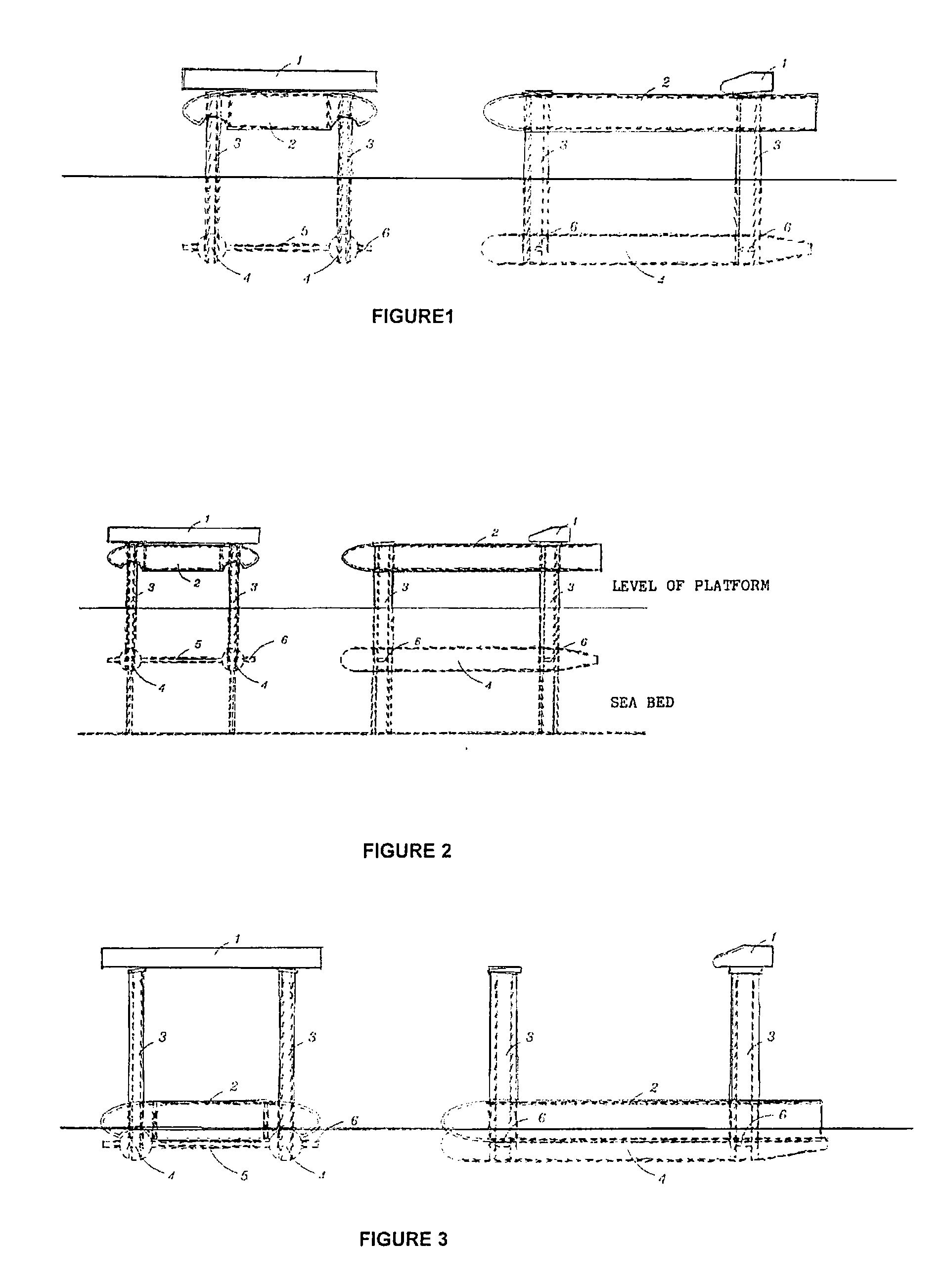

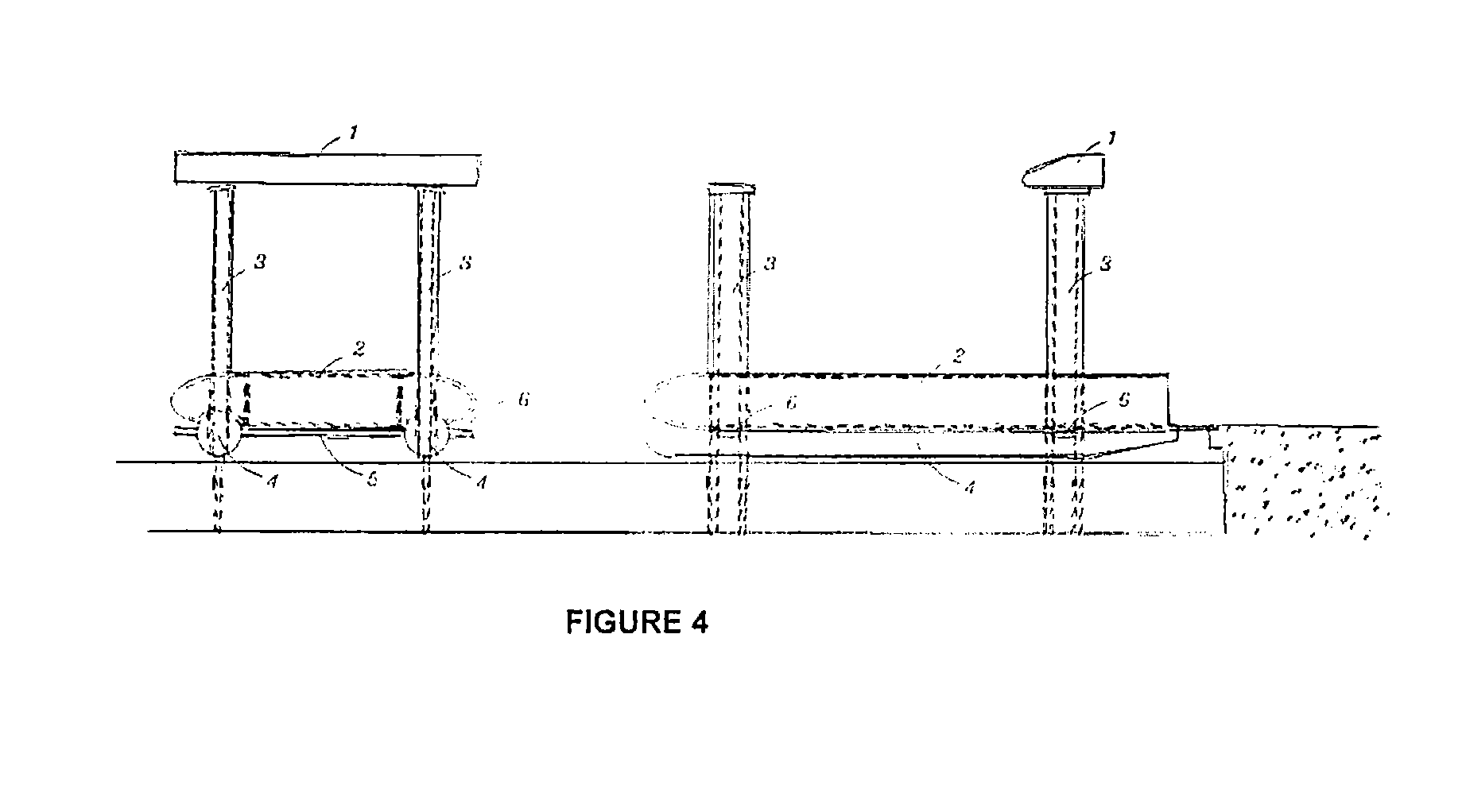

[0027]The new design of vessel forming the subject-matter of this invention is characterised by having its displacement made up of two parallel submerged bodies, clearly cylindrical in cross-section or as hydrodynamic as possible, joined by hydrodynamic profiles.

[0028]Four hydrodynamic legs are located in the confluence between the cylinders and the profiles capable of supporting a platform or loading zone which can move (up or down) on the legs to raise itself above the level of the waves.

[0029]Within the legs there are hydraulic pistons of equal length and which cross the cylinders and are joined to tangential plates outside the cylinders for deep support of the pistons.

[0030]The upper works (or non-submerged part of the vessel) has pinions which can move it above the legs which are fitted with a rack to the level necessary to navigate at sea level. The rack and pinion system can be replaced by any equivalent system of vertical displacement.

[0031]The engine room, motors, the bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com