Method of improving the efficiency of loosely packed solar cells in dense array applications

a solar cell and dense array technology, applied in the field of solar cell array assembly, can solve the problems of low efficiency of solar cells, and low efficiency of solar cells, and achieve the effect of maximum utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

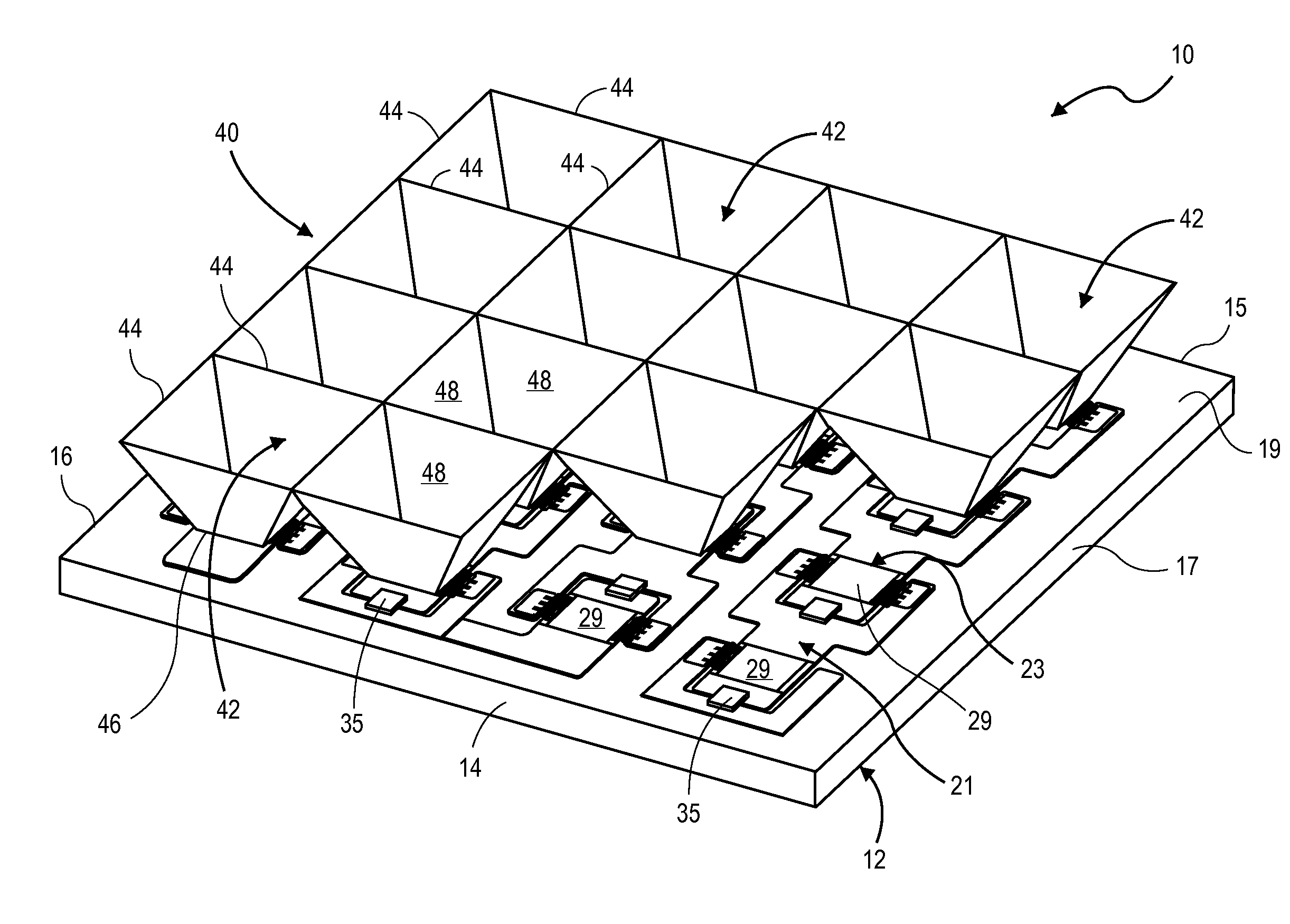

[0012]The increased efficiency Concentrator Photovoltaic (PV) System will now be described by referring to FIGS. 1 and 2 of the drawings. The PV System is generally designated numeral 10. It has a substrate 12 having a front end 14, a rear end 15, a left end 16, a right end 17 and a top surface 19. Substrate 12 may be made of a non-electrical conducting material or a conducting material such as metal in which the top surface has been rendered non-conductive by application of a surface treatment or coating on the non-conductive material.

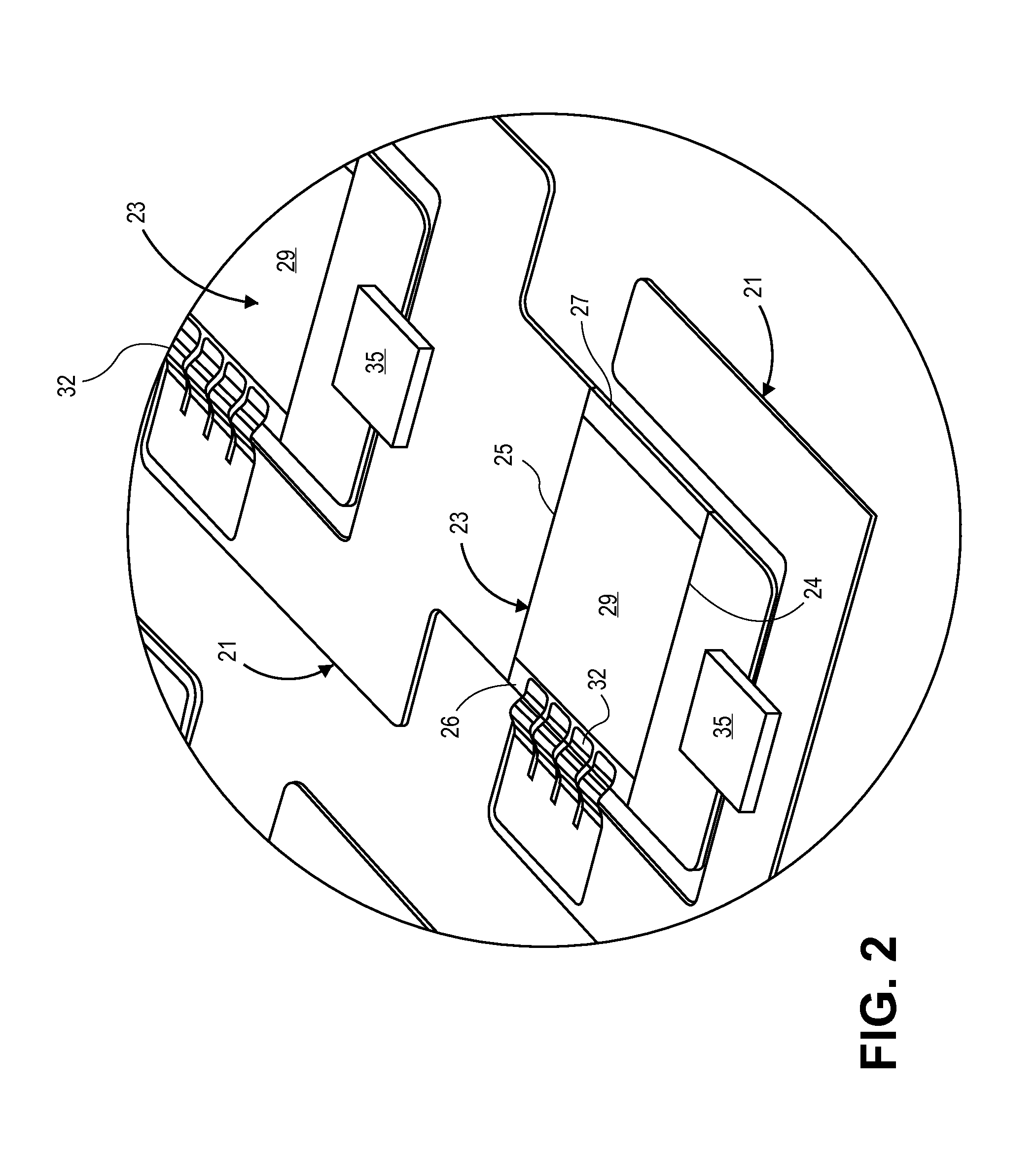

[0013]A plurality of metal traces 21 are located on top surface 19 and they provide a surface upon which the solar cells 23 can be supported and also provide a path for the electrical output of the individual solar cells 23. The solar cells 23 have a front edge 24, a rear edge 25, a left edge 26, a right edge 27 and a top surface 29. Top surface 29 is the active area that receives the solar rays that produce electricity. Metal ribbons / wires 32 provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com