Method for fabricating a footwear sole

a technology of footwear soles and moulds, which is applied in the field of moulds for making footwear soles, can solve the problems of poor air permeability, fatigue of feet, and deformation of the forefoot, and achieve the effects of good air permeability, easy operation, and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The preferred embodiments of this Invention will now be described by referring to the attached drawings.

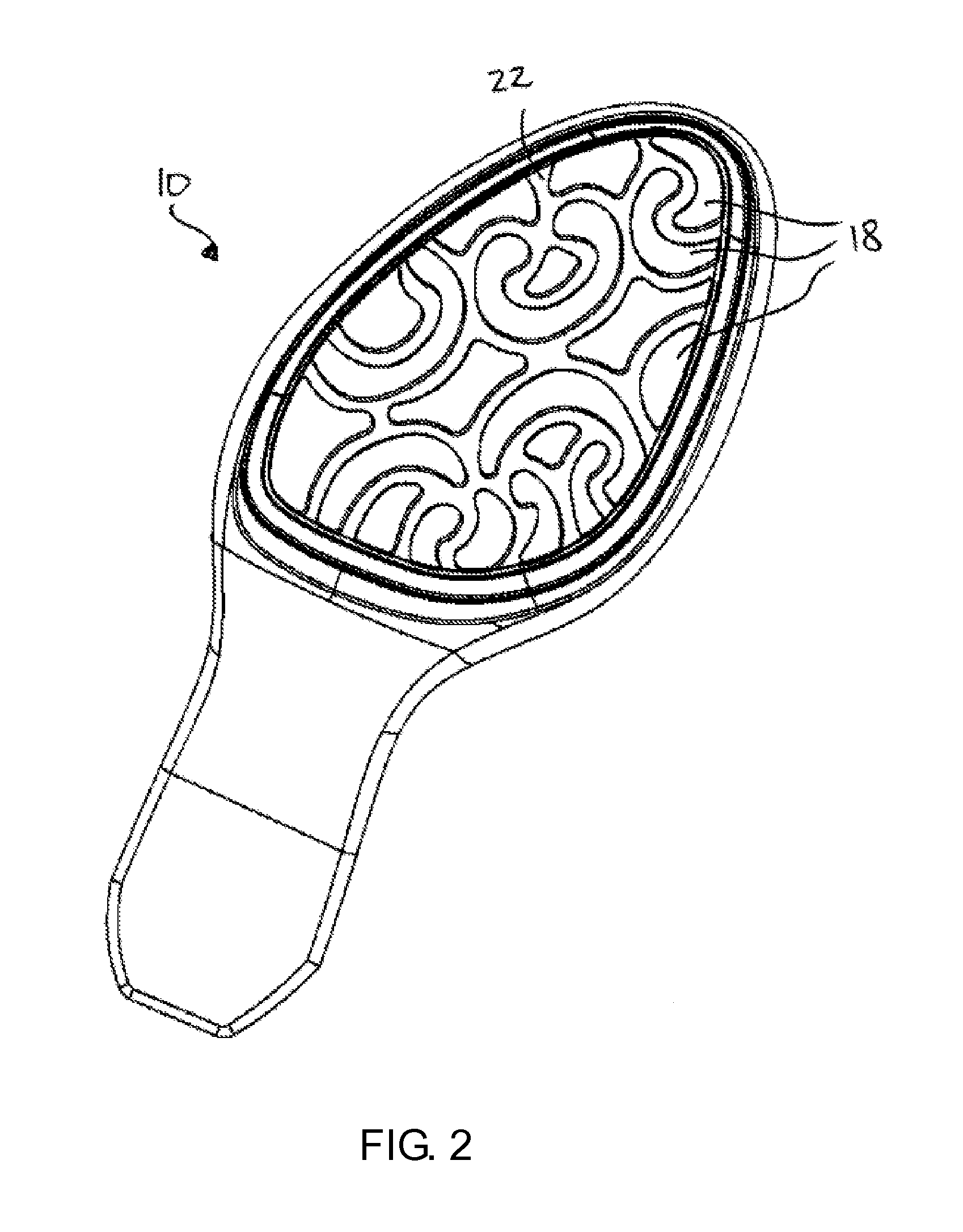

[0029]Now referring to FIG. 1 and FIG. 2, there illustrated a shoe sole 10 fabricated according to a method of the present invention. The shoe sole has good air permeability and is suitable for long-time wear, as mentioned in the Background. This shoe sole 10 fits snugly with the foot (not shown) by automatically adapting itself to the shape of the foot. The main body or midsole layer 12 of the fore sole 14 is illustratively a leather layer which is primarily made of leather materials. By way of injection-moulding soft plastics, one or more first raised sole lines 16 and one or more second raised sole lines 18 are formed respectively on an underside 20 of the midsole leather layer 12 to thus form an outer sole portion 19 and an upper surface 22 of the midsole leather layer 12 to thus form an inner sole portion 17. A rear part 24 of the sole 10 is also obtained by injection-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com