Multiple projectile ammunition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

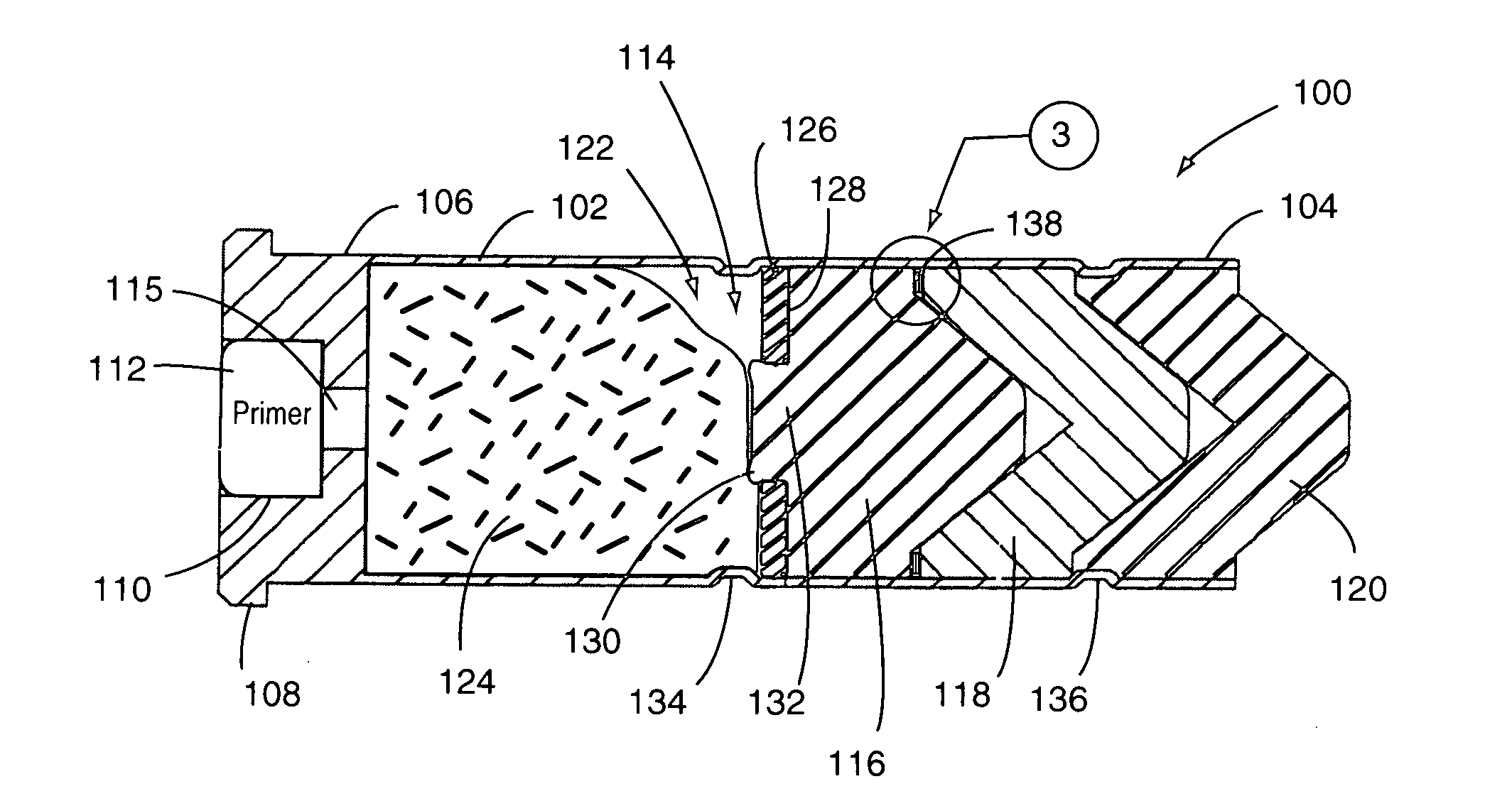

[0013]FIGS. 1 and 2 show a round of ammunition (e.g., a cartridge 100) configured in accordance with an embodiment of the present invention. The cartridge 100 includes a casing 102 having a projectile receiving end portion 104 and a primer receiving end portion 106. A rim 108 and a primer bore 110 are provided at the primer receiving end portion 106. The primer bore 110 is configured for having a primer 112 mounted therein. It is disclosed herein that a water-resistance seal can be provided between the primer 112 and the casing 102 by providing a suitable sealant between the primer 112 and a mating wall of the primer bore 110.

[0014]The casing 102 has a substantially round cross sectional shape. The projectile receiving end portion 104 defines an open end portion of the casing 102. The primer receiving end portion 106 defines a closed end portion of the casing 102 (i.e., when the primer 112 is within the primer bore 110. A casing cavity 114 is defined between the projectile receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com