Vent Assembly For A Grain Bin

a technology for venting and grain bins, which is applied in ventilation systems, lighting and heating apparatus, heating types, etc. it can solve the problems of affecting affecting the ventilation performance of the grain bin, and the proportion of the grain bin roof to deteriorate, so as to prevent the build-up of moisture and debris, and prolong the life of the grain bin roo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

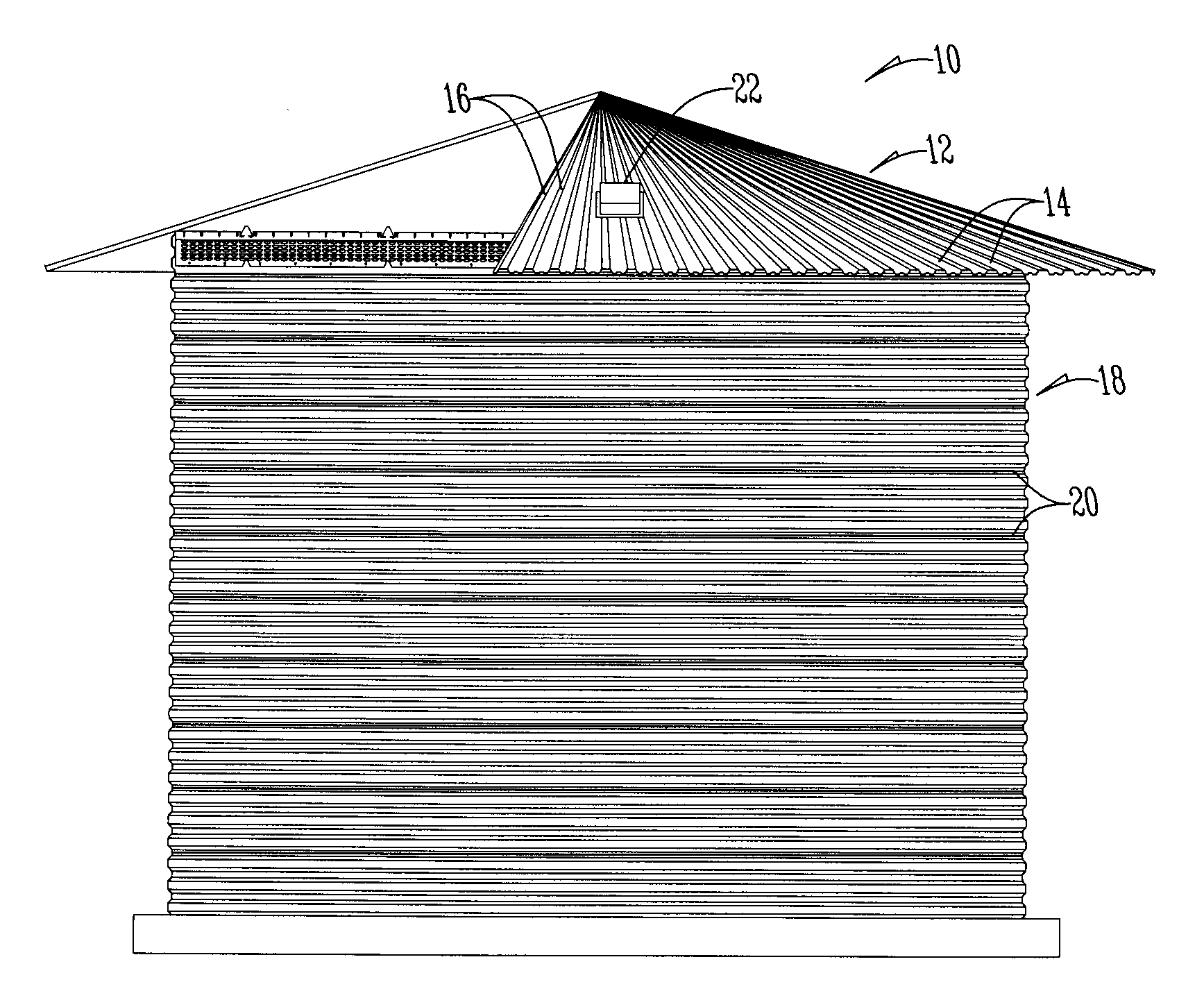

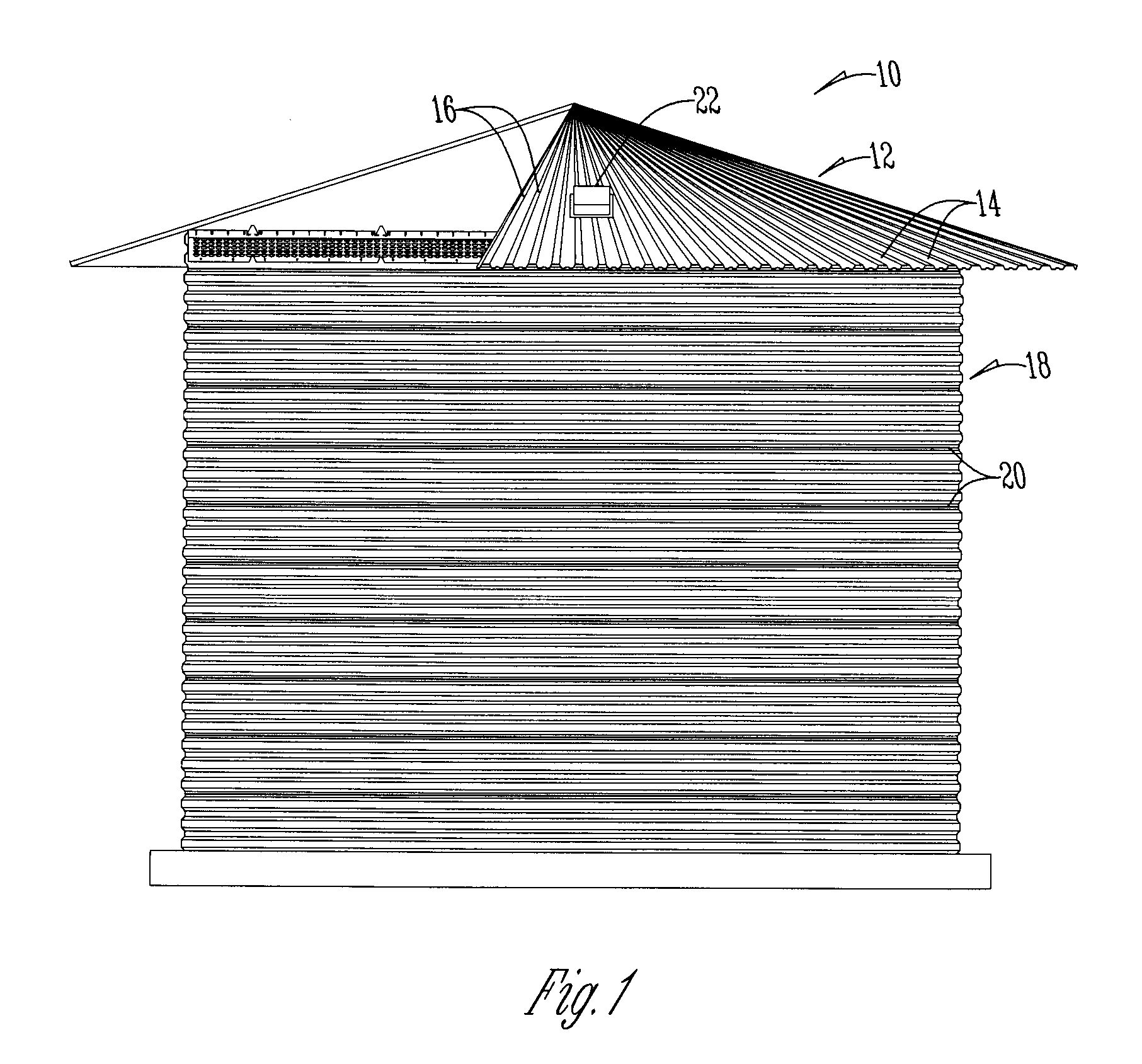

[0018]A grain drying bin 10 has a roof structure 12 having triangular roof panels 14 joined together at rib junctions 16. The bin 10 also has a cylindrical sidewall wall 18 generally formed from corrugated metal panels 20. Connected to the roof 12 is a plurality of roof vent assemblies 22.

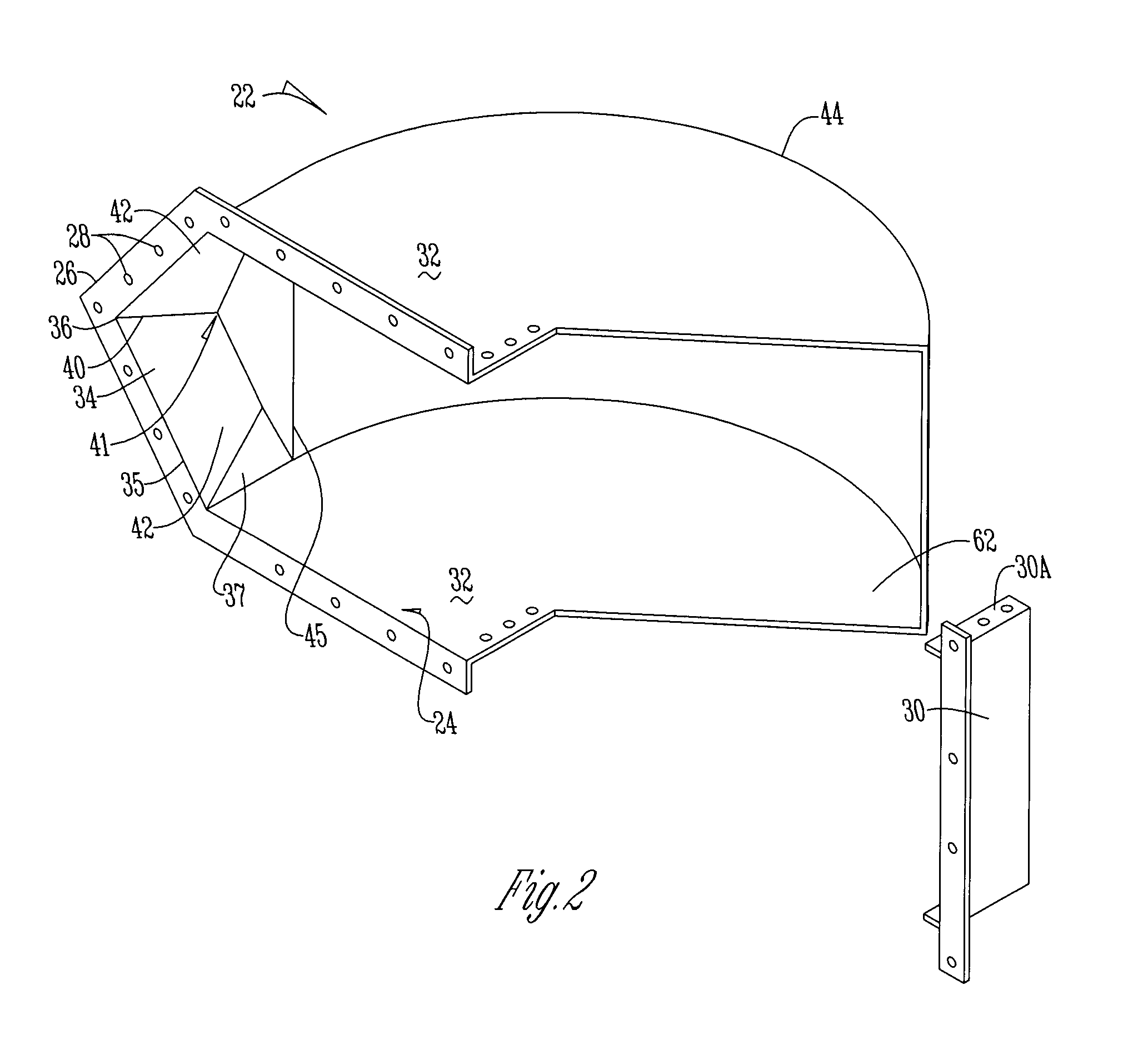

[0019]The vent assembly 22 has a base 24 with an outwardly extending flange 26. The flange 26 has a plurality of apertures 28 used for connection to the roof 12. The base 24 has a back or lower wall 30, sidewalls 32, and a front or top wall 34 that form an enclosure that fits over and is in communication with an opening in the roof assembly. Preferably, back wall 30 is removably attached to the sidewalls 32 by flanges 30A that extend from the back wall toward the front wall 34.

[0020]The front wall 34 has a lower edge 35 that extends from the sidewalls 32 to a point, peak or rounded crest 36. The front wall also has an elongated portion 37 that extends between the sidewalls 32. From point 36, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com