Construction method of cellar for building completed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0066]FIGS. 16 to 19 illustrate a construction method of a cellar for a building completed according to the present invention.

[0067]In the construction method according to the second embodiment of the present invention, the cellar 12 can be constructed without perforating bottom concrete 2 in the completed building 1.

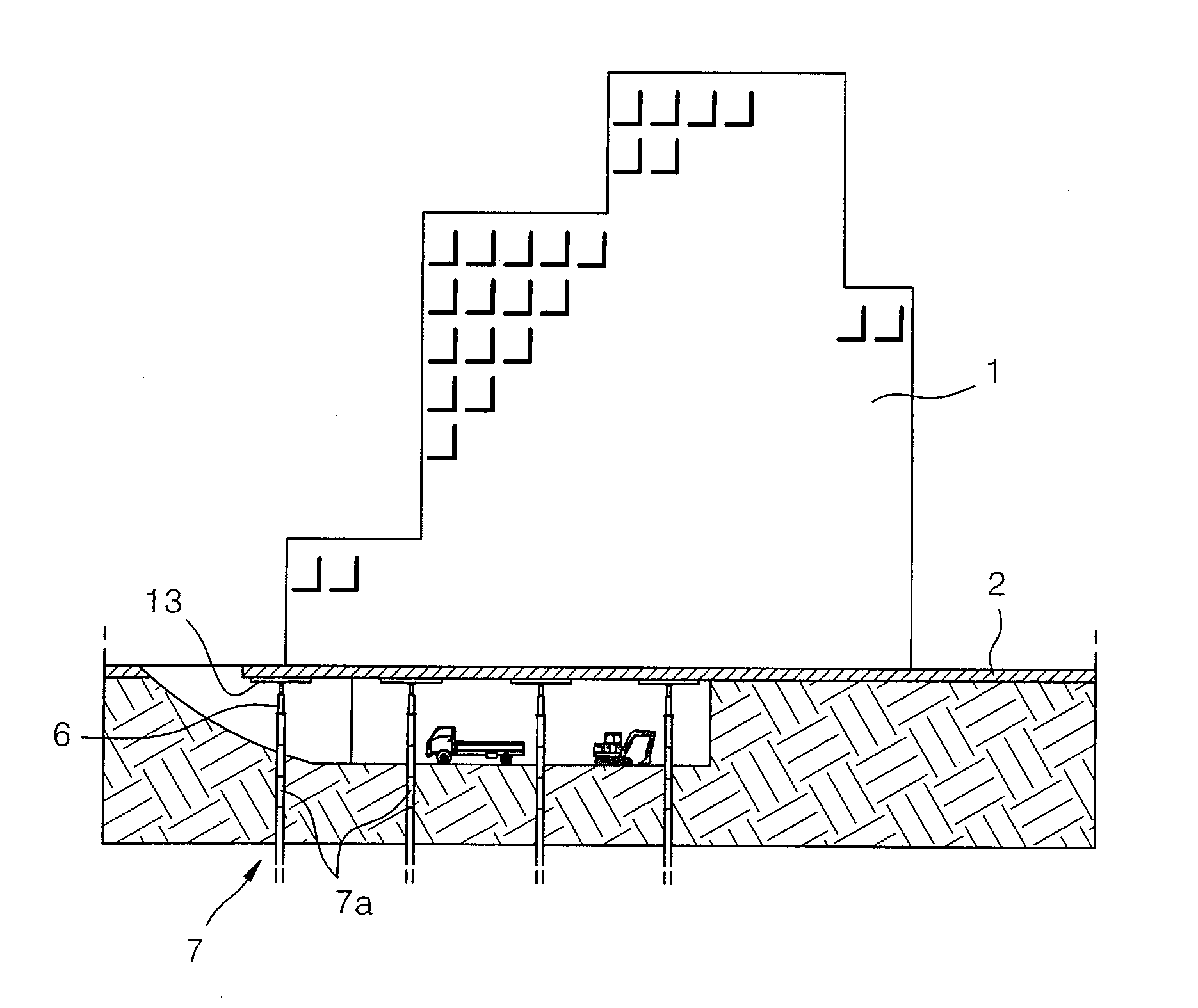

[0068]As shown in FIG. 16, in the construction method according to the second embodiment of the present invention, a foundation of one side of the completed building 1 is excavated, a press-in machine 6 is installed under the exposed bottom concrete 2, and piles 7a are inserted into the foundation at a position at which the press-in machine 6 is installed, thereby forming posts 7.

[0069]After forming the posts 7, the foundation around the posts 7 is excavated. After excavating the foundation, the press-in machine 6 is installed under the exposed bottom concrete 2 in the same manner as described above. Next, the piles 7a are inserted to form the posts 7. As the aforementi...

third embodiment

[0073]FIGS. 20 to 23 illustrate a cellar construction method of a completed building according to the present invention.

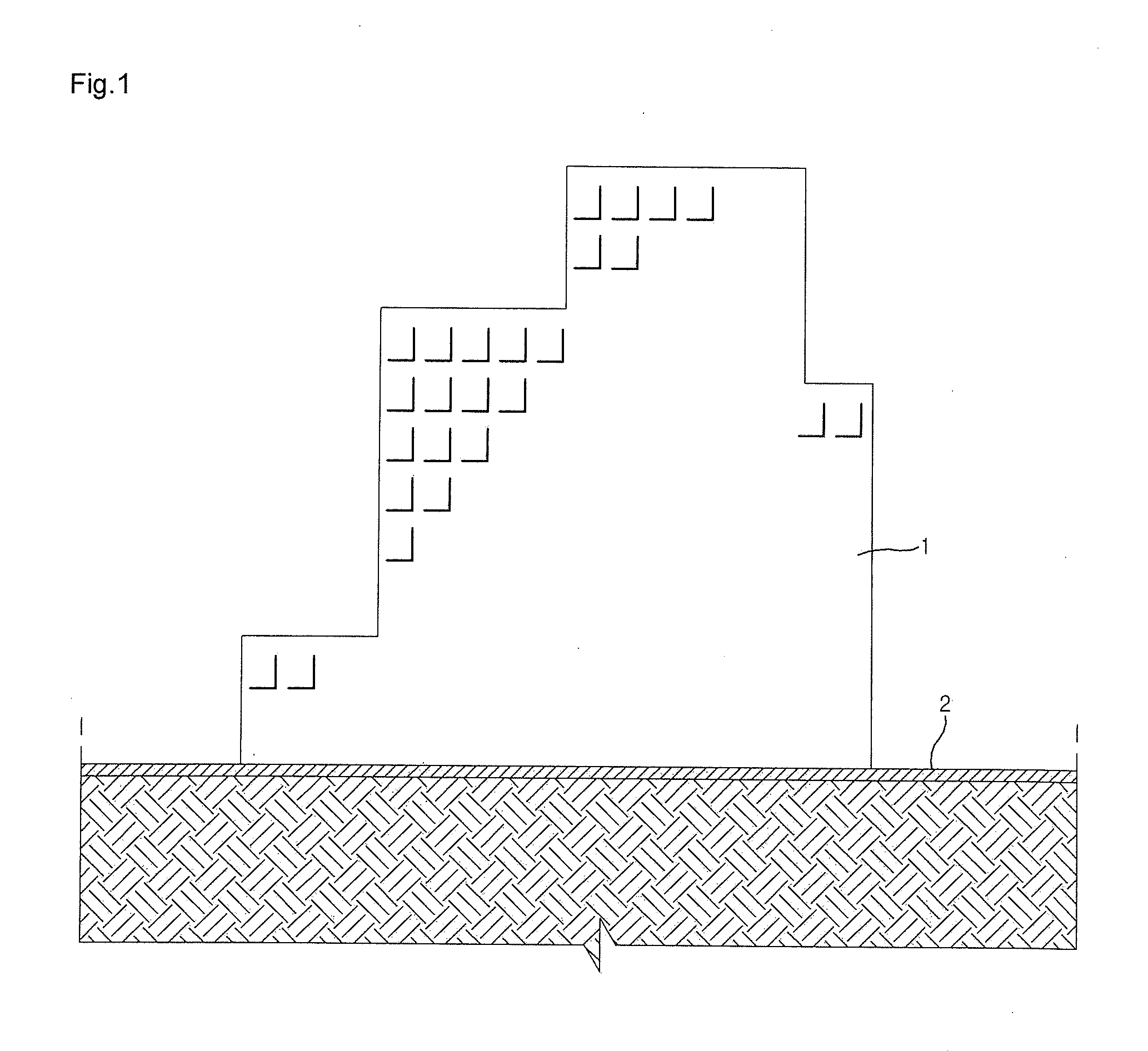

[0074]The cellar construction method according to this embodiment is suitable for constructing the cellar 12 in a small-scale completed building shown in FIG. 20.

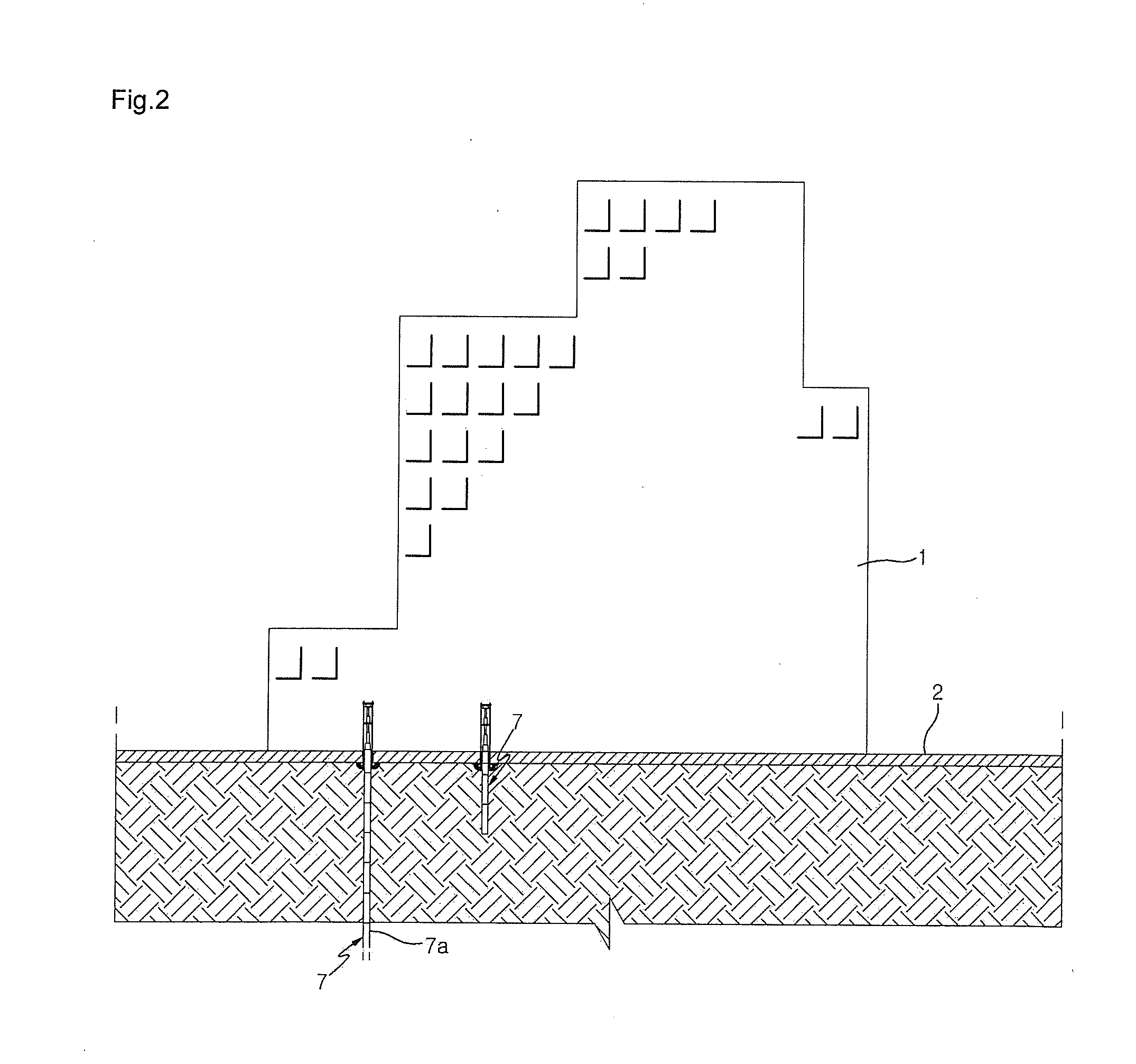

[0075]In the construction method according to the third embodiment of the present invention, as shown in FIGS. 21 and 23, holes and slots are formed in bottom concrete 2 of outer edges of the completed building 1, supporting structures 5 are fixed to corresponding positions, and a press-in machine 6 is installed.

first embodiment

[0076]The installing of the supporting structures 5 and the press-in machine 6 are the same as those of the

[0077]As described above, the plurality of supporting structures 5 and the press-in machine 6 are installed on edges of the building 1, and piles 7a are inserted into the ground to form a plurality of posts 7 for supporting the hollow building 1. A foundation of the bottom concrete 2 under the building 1 is excavated and bottom and side surfaces of concrete 9 are finished to form the cellar 12.

[0078]Like the previous embodiment, in the present embodiment, in a case where the bottom concrete 2 is not strong enough to bear the reaction transmitted by the supporting structures 5, the strength can be enhanced by additionally installing a support plate 13 on or under the bottom concrete 2 when inserting the piles 7a into the bottom concrete 2 on the edges of the hollow building 1.

[0079]As described above, unlike in the first embodiment, in the second and third embodiments, since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com