Systems and methods for thermal management of electronic components

a technology of electronic components and thermal management, applied in the direction of insulated conductors, cables, lighting and heating apparatus, etc., can solve the problems of insufficient heat transfer efficiency, inability to achieve the effect of facilitating thermal energy transfer, and reducing the number of contact points of the interface, so as to facilitate the transfer of thermal energy, facilitate the dissipation of heat, and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0056]FIG. 5 shows a graph comparing the frequency and resistivity of carbon nanotube wires with the frequency and resistivity of Aluminum and Copper wires. Specifically, this experiment was conducted using a 6-ply non-insulated carbon nanotube wire and 35 AWG gauge Aluminum and Copper wires at 20° C. and 100° C. The electrical measurements performed were conducted with less than about 1 Watt.

[0057]As shown in FIG. 5, bulk materials composed of carbon nanotubes exhibit improvements in conductivity at higher frequencies. For example, at about 1.E+05 Hz, bulk materials composed of carbon nanotubes exhibit a drop in resistivity from about 1.E-04 Ω-cm to about 1.E-05 Ω-cm. In some cases, carbon nanotube wires may be doped for better electrical behavior.

example 2

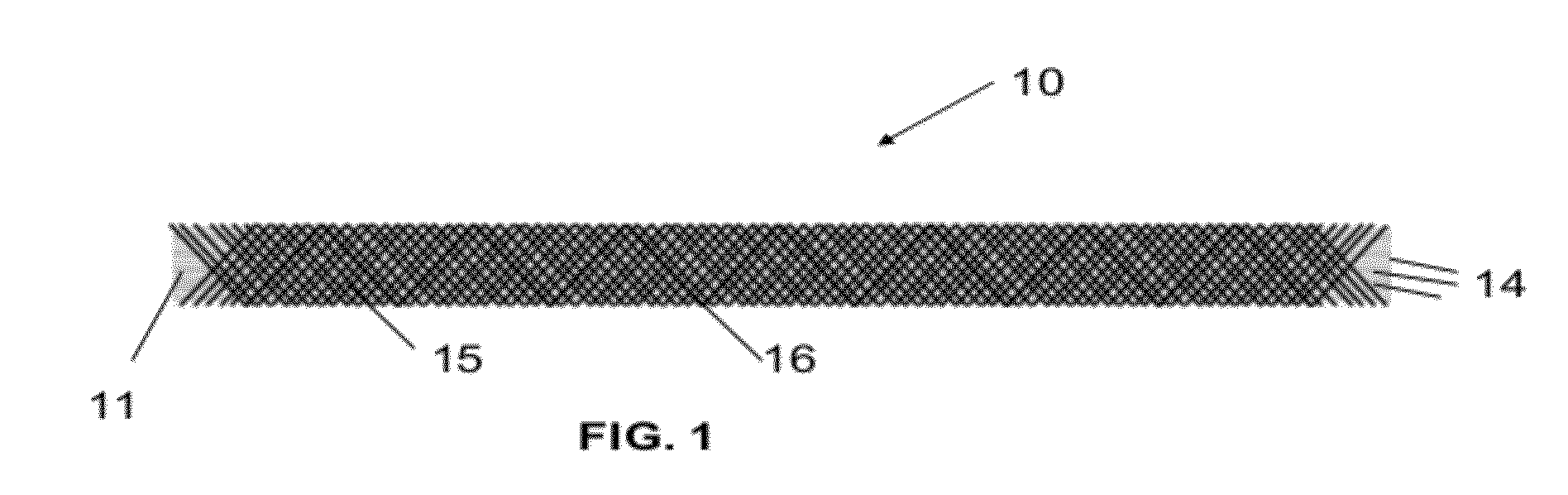

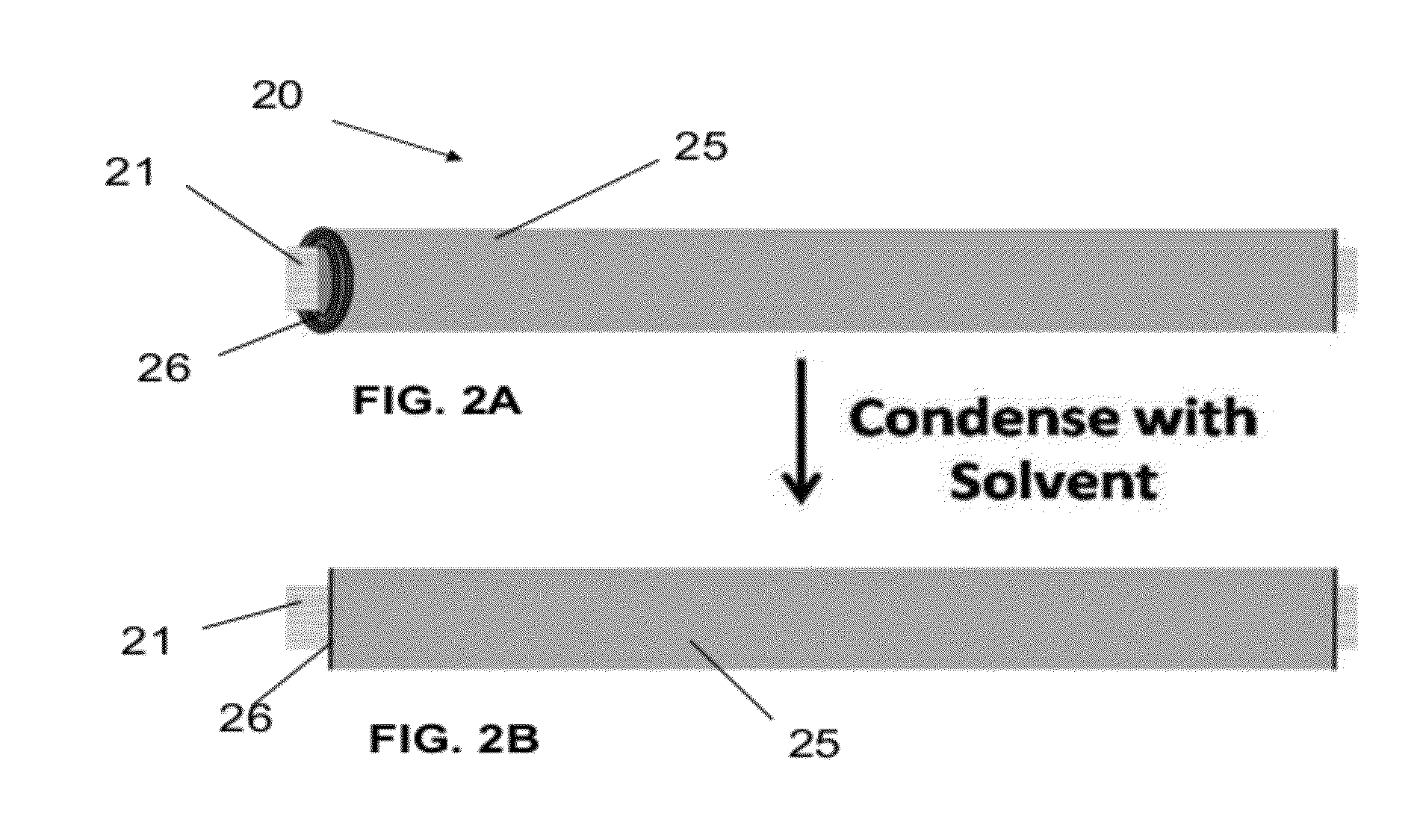

[0058]An experimental setup for testing the temperature versus power of the thermal management devices included using two sets of carbon nanotube wires. The first set included two six-inch samples of non-insulated large diameter carbon nanotube wires. The diameters of the carbon nanotube wires includes plies of 25 (˜29 AWG), 50 (˜26 AWG), 100 (˜23 AWG), and 150 (˜21 AWG). These carbon nanotube wires were formed and plated with nickel followed by copper on both ends. The second set included the same diameter carbon nanotube wires that were insulated with a zero inner diameter shrink tubing rated to 300° C. Each set was hung in air, and a DC power supply was used to run current through and a voltage across the sample. The Power applied ranged from about 0 Watts to about 10 Watts. The power supply was set to be current limiting and readings were taken every half volt once the temperature stabilized. The temperature measured ranged from about 0° C. to about 200° C. The temperature was m...

example 3

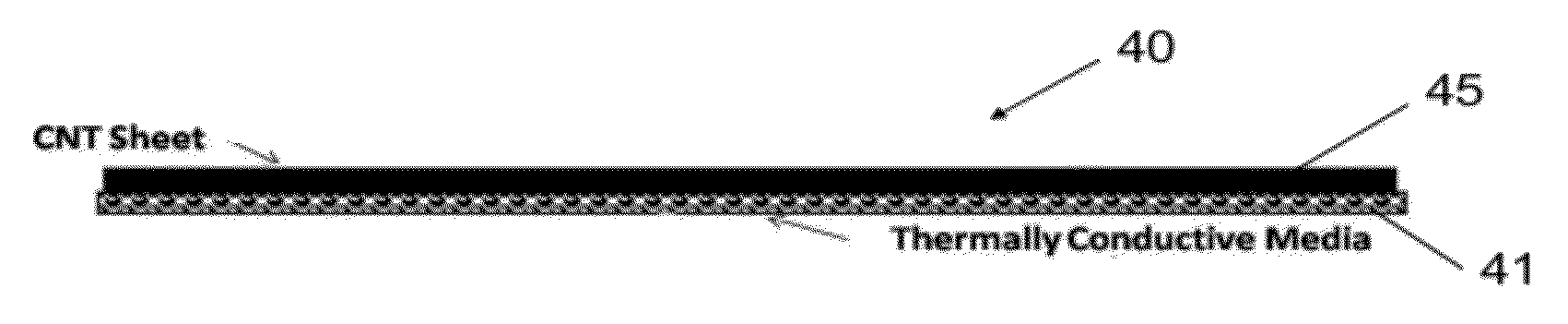

[0060]An experimental setup for testing the temperature versus power of the thermal management devices included using a sheet of carbon nanotube electrical conductor (i.e., electrically conductive member) and laminating with a thin layer of a high thermally conductive graphite (i.e., thermally conductive member). The resulting laminated structure was then rolled tightly to form a cylinder approximately six inches long. The sample was hung in air, and a DC power supply was used to run a current through and a voltage across the sample. The Power applied ranged from about 0 Watts to about 10 Watts. The power supply was set to be current limiting and readings were taken every half volt once the temperature stabilized. The temperature measured ranged from about 0° C. to about 200° C. The temperature was measured with Wahl Heat Spy HSI3000 Thermal Imager. The response is shown in FIG. 7 and is compared to the pure carbon nanotube (CNT) conductor without any thermal dissipation assistance....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com