Truss Cable Semi-submersible Floater for Offshore Wind Turbines and Construction Methods

a technology of truss cable and floater, which is applied in the direction of special-purpose vessels, vessel construction, transportation and packaging, etc., can solve the problems of large oil and gas steel structure and hull form, and achieve the effects of improving stability, structural strength and dynamic performance, and reducing cost and weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

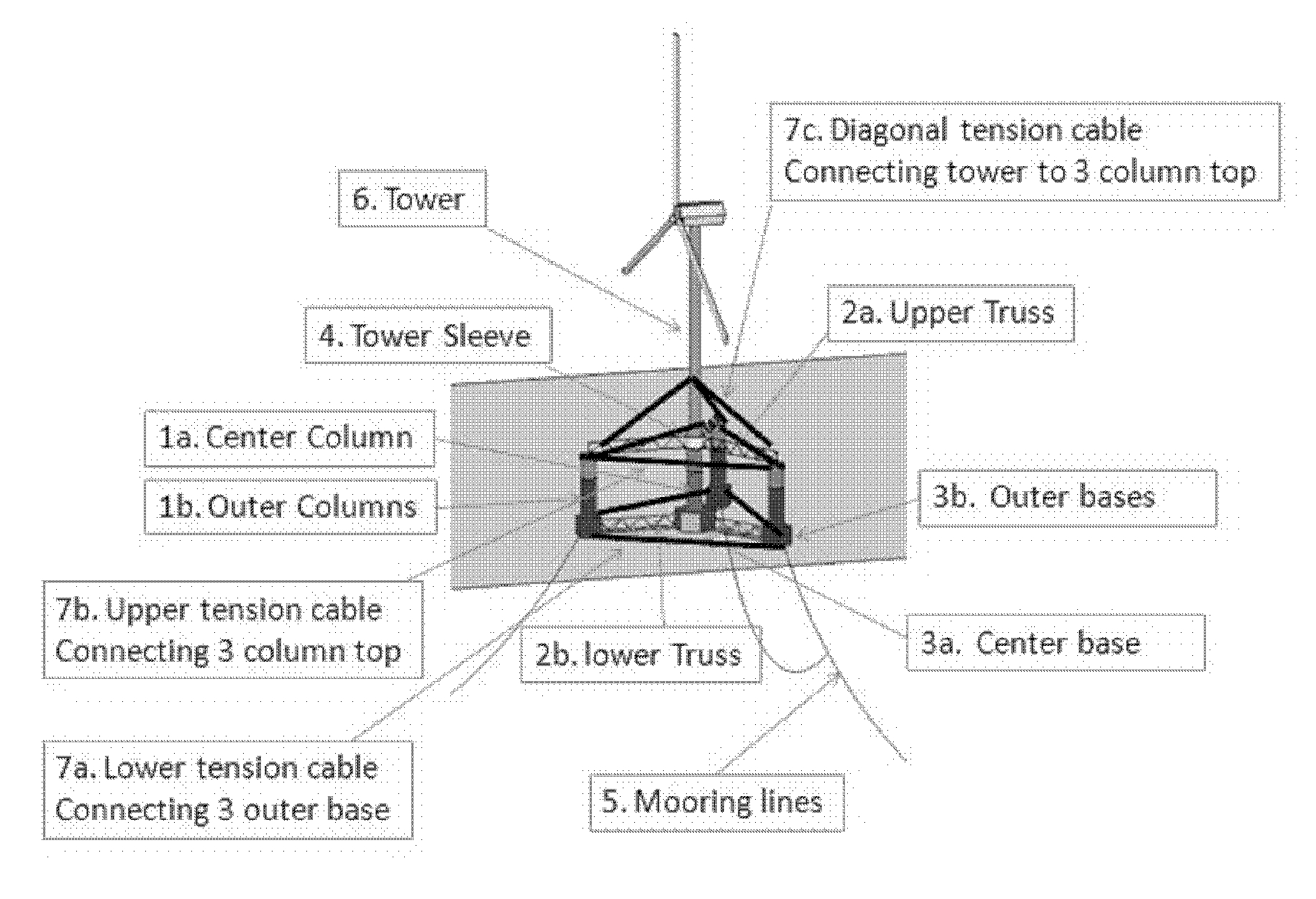

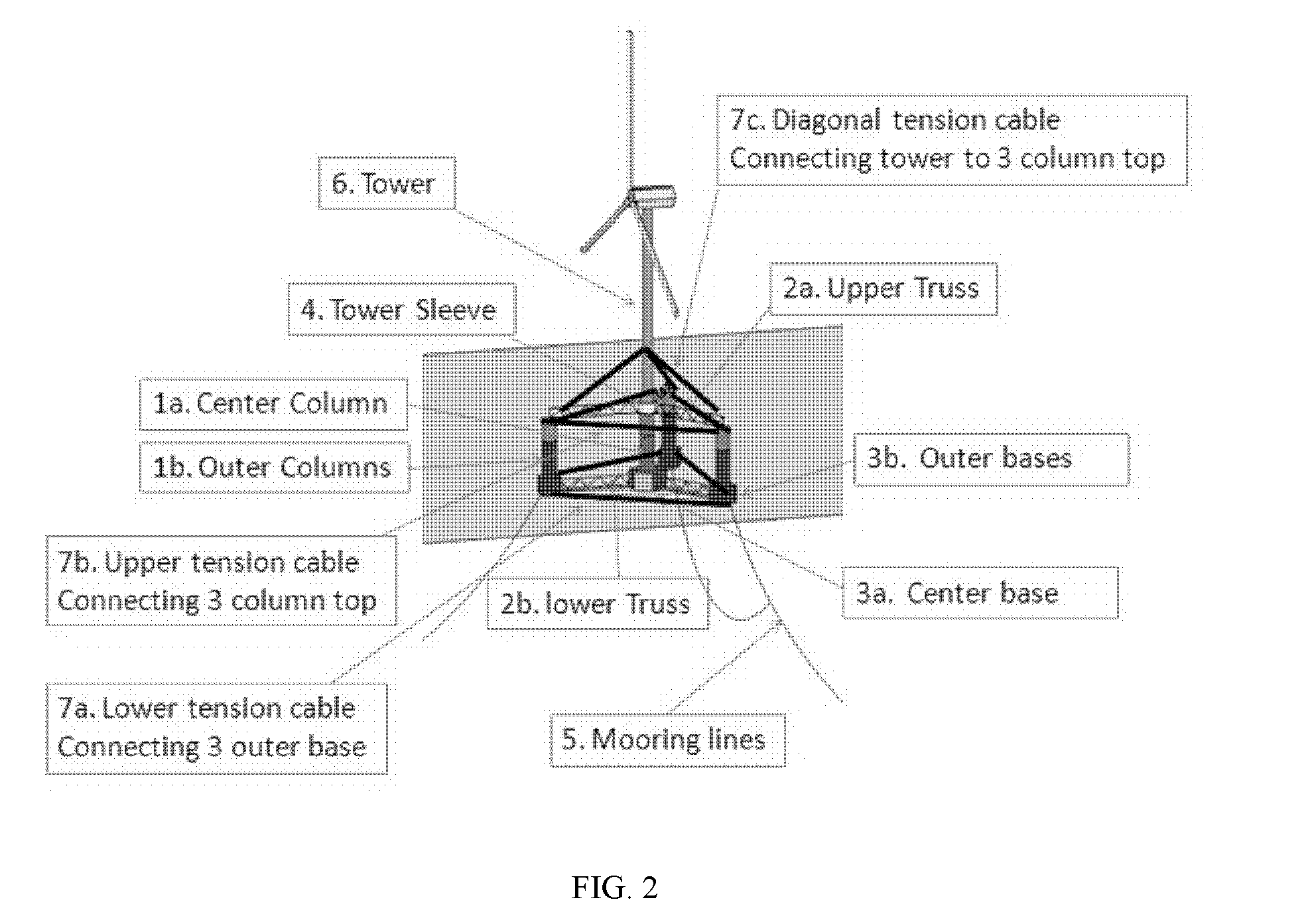

[0016]With reference to FIG. 2, a truss cable semi-submersible floater (hereinafter referred as “floater”) includes a hull, a tower, and a tensioned cable system. The hull mainly includes 3 components: columns, including a center column 1a and outer columns 1b, trusses coupled to the columns, including an upper truss 2a and a lower truss 2b, and column bases coupled to the columns and the trusses, including a center base 3a and outer bases 3b. The hull can have multiple outer columns for stability, typically 3 columns (as shown in FIG. 2), but also can have 4 columns or more. The hull has an in-service draft in the order of 60 ft to 80 ft depending on metocean conditions of the deployed area. The columns are most buoyant to provide the buoyancy for the wind turbine and rotor blades, which can be coupled with the floater and located above the water surface. The column bases, which can be tanks, provide stability for wet tow and hold ballast (sold or water ballast) for inplace conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com