Universal Sole

a technology for soles and shoes, applied in the field of soles for shoes, can solve the problems of not being able to adapt to the various kinds of ground, not being able to find readymade and affordable corrective shoes for sports, and needing a different pair of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

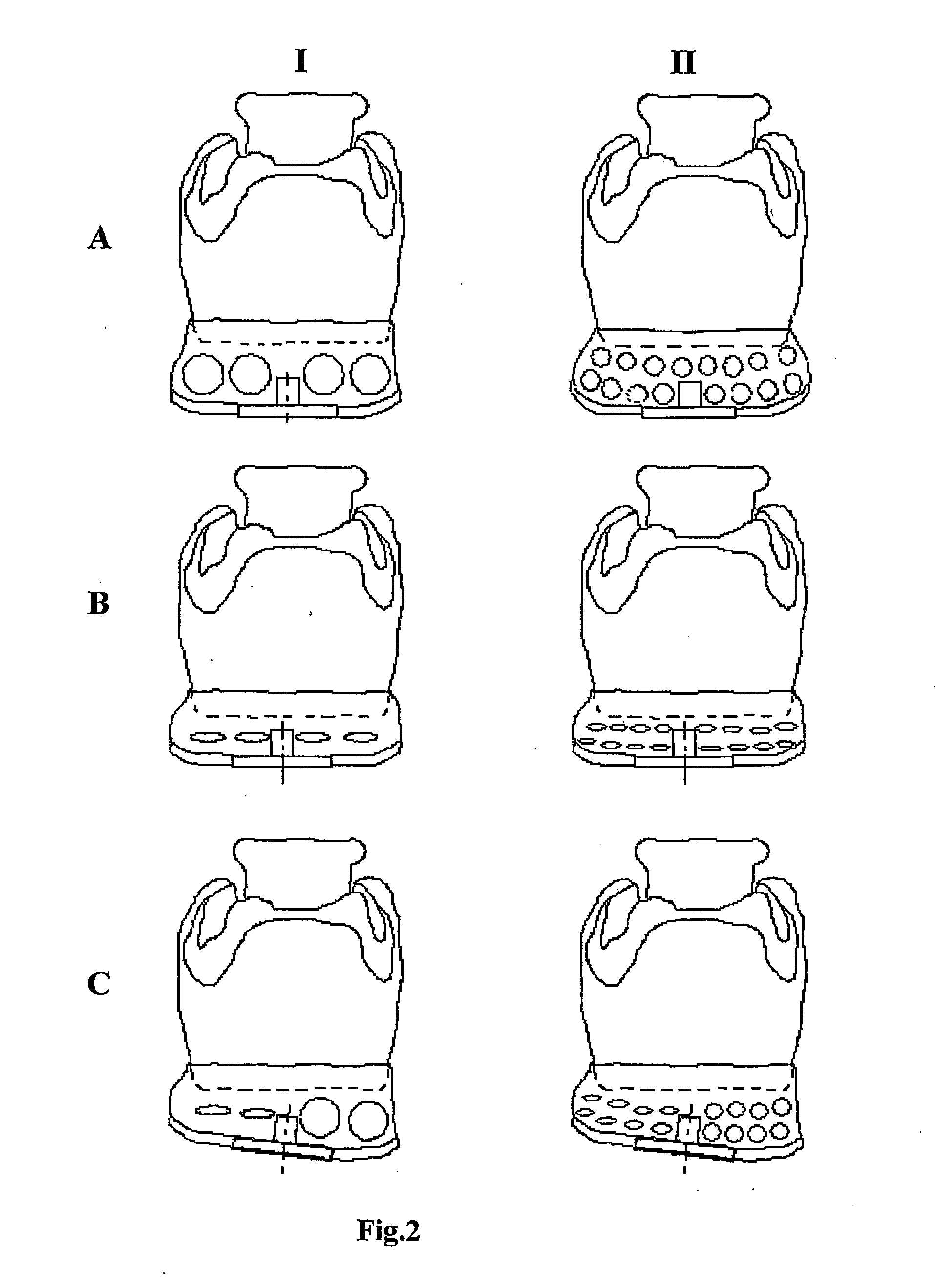

[0095]The best standard method to carry out the invention consists in manufacturing a sole assembly using a coil made of four zones, front right, front left, right heel and left heel and made of a nylon-reinforced rubber tube of diameter 8 mm and 2 mm wall thickness. The diameter under maximum pressure is 14 mm. A single layer of coil is used in the front zones two layers are used in the heel zones. The valves block houses the six needle valves isolating the four zones, the suction of a plunger-pump with a convex disk located under the heel, the vent and its filter.

[0096]The spaces between the coil's tubes are filled by layers of pre-cut foam, made of a type of vinyl acetate ethylene copolymer (eva) for example, ridged and pre-imprinted with the coil path. One thus has a lower foam layer whose upper face, ridged and imprinted with the coil path, is pre-glued; a set composed of the coils, valves block and pump is placed upon it, then an intermediary foam plate whose lower face is rid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com