Self centering hinge design for concentric sealing of an enclosure

a hinge design and enclosure technology, applied in the direction of cell components, cell component details, transportation and packaging, etc., can solve the problems of enclosure seals that cannot be sealed properly, enclosure seals may be compromised, and seal arrangements suffer from various drawbacks, so as to achieve uniform compression of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

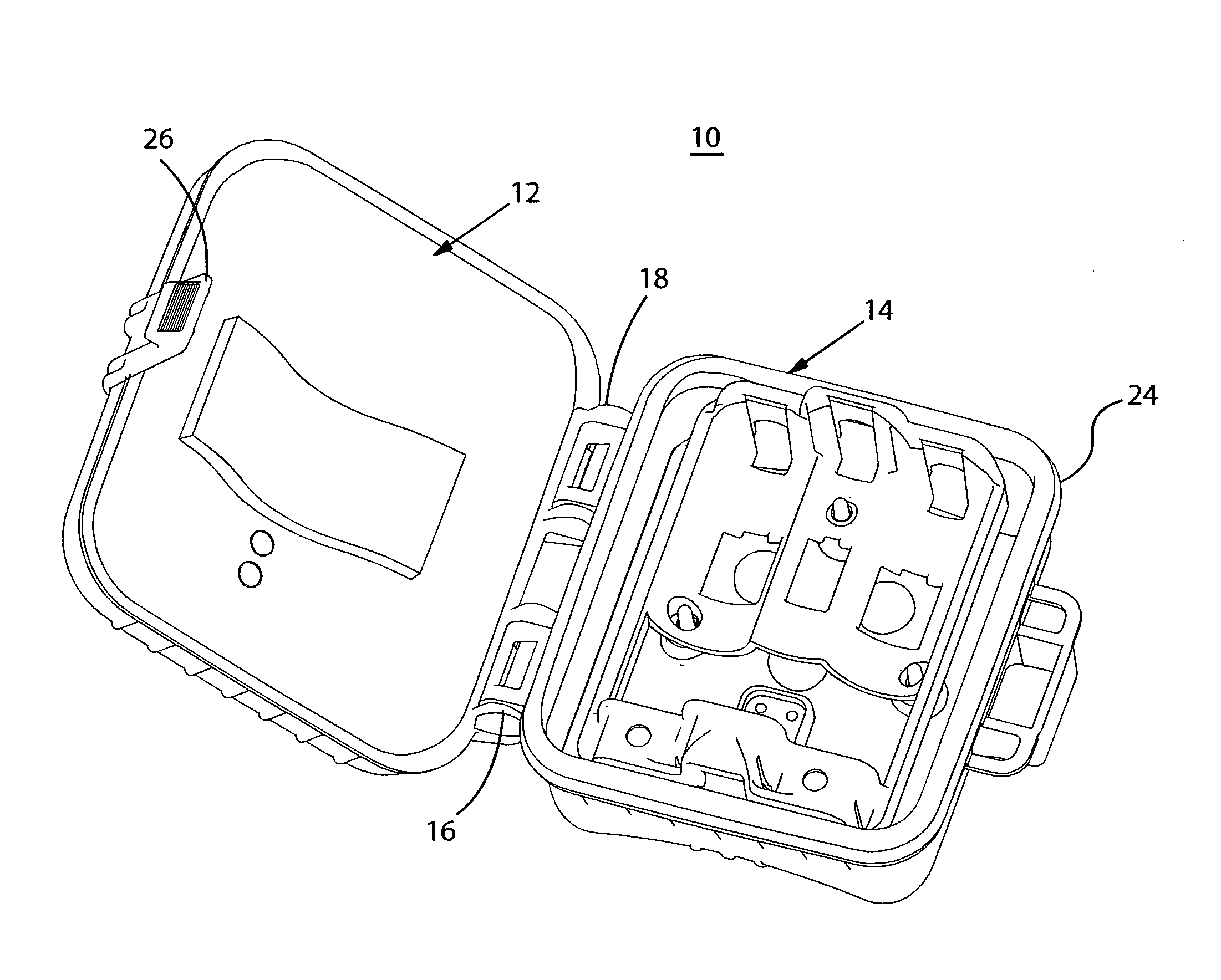

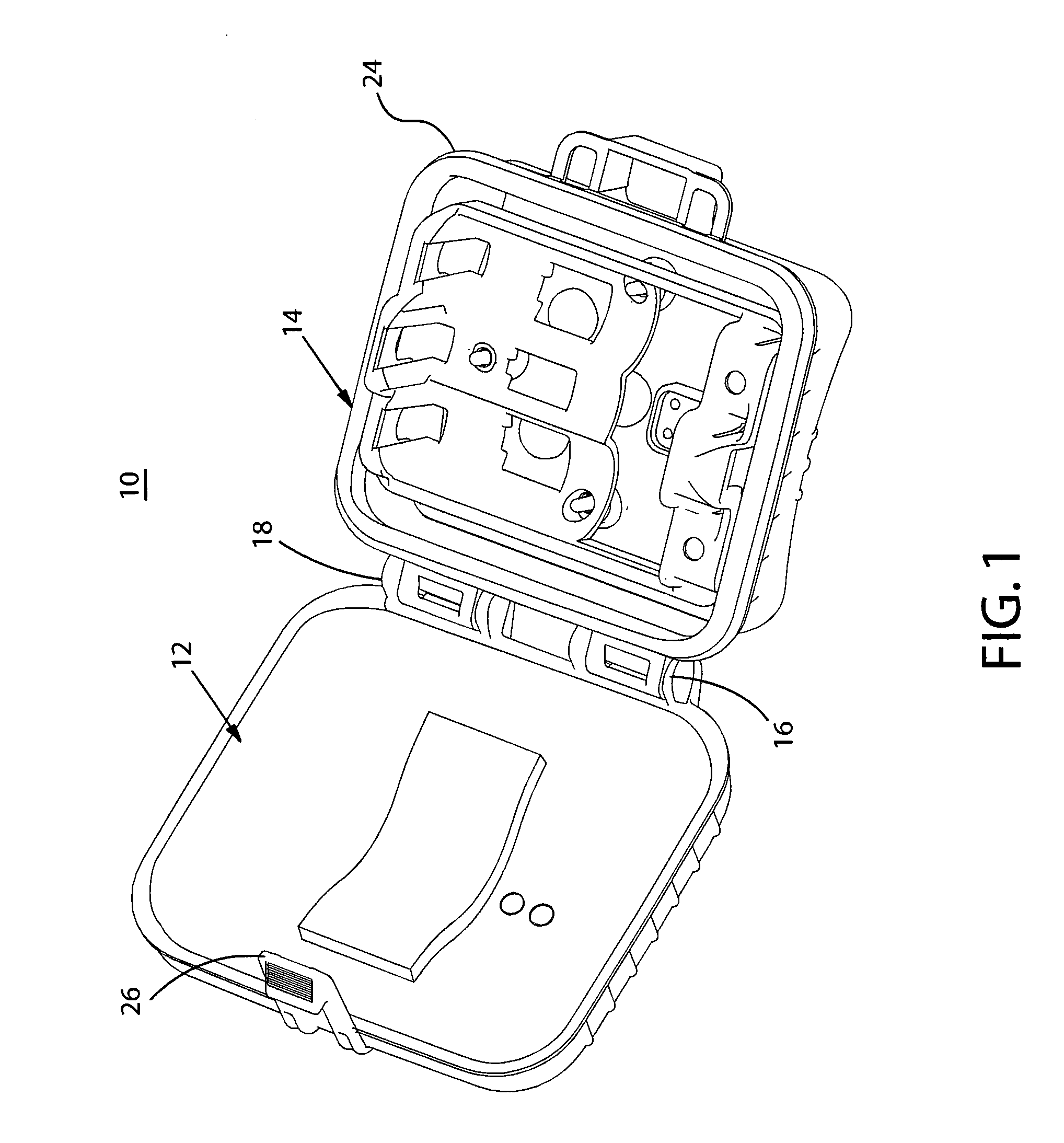

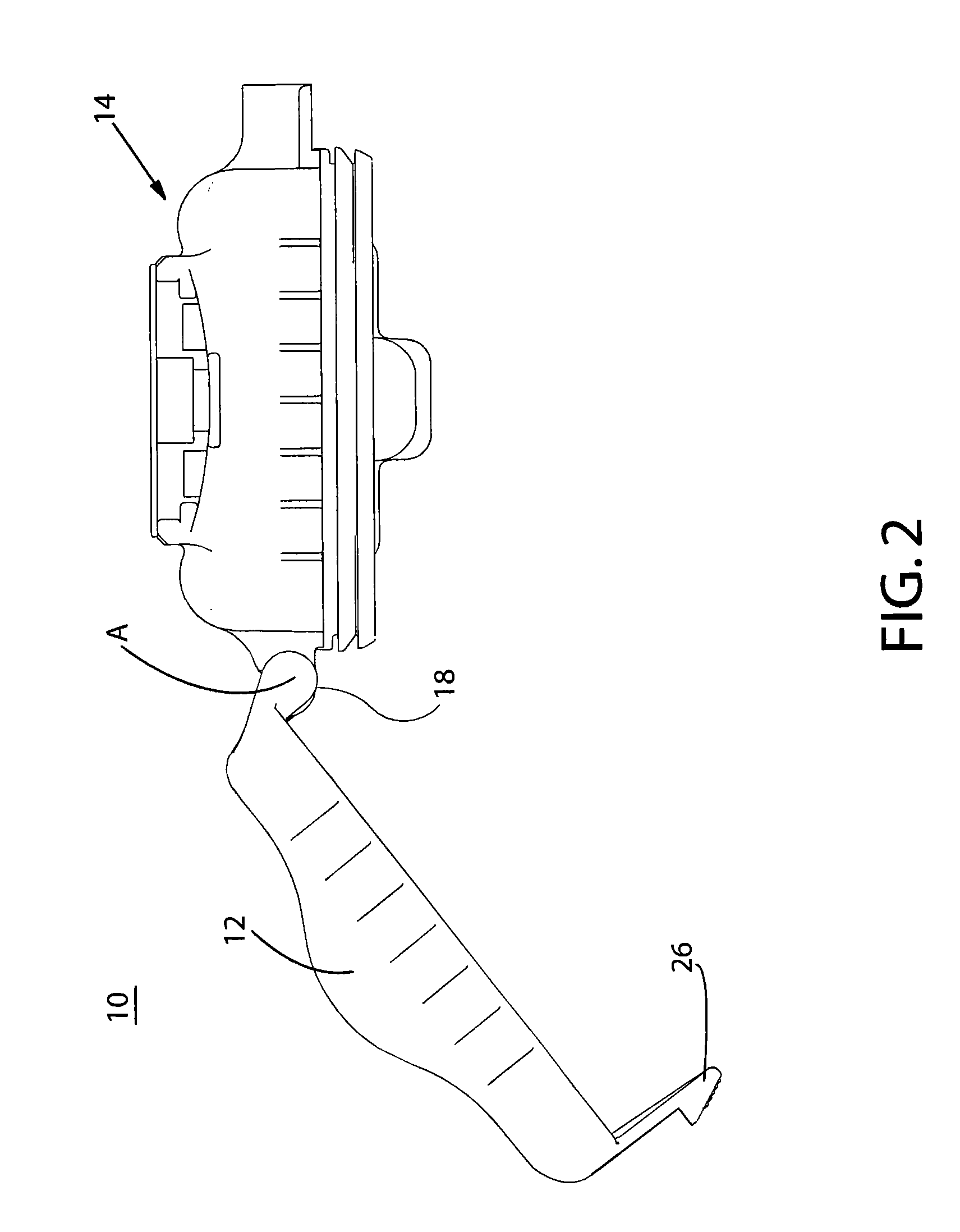

[0019]Referring generally to the figures, and according to one aspect of the invention, a waterproof, clam-shell style enclosure 10 comprises a first cover 14; a second cover 12 that is hingedly coupled to the first cover 14 to pivot about an axis of rotation ‘A’ between an open state and a closed state, wherein, in a closed state, the first cover 14 and the second cover 12 define an enclosed interior region of the enclosure 10. A seal 24 is positioned on a sealing surface 23 of either the first cover 14 or the second cover 12, wherein the seal 24 is positioned to inhibit the passage of fluid into the enclosed interior region of the enclosure 10 in the closed state of the enclosure 10. A hinge 16, 18 is configured to accommodate translation of the second cover 12 with respect to the first cover 14 in the ‘X’ and ‘Y’ directions upon pivoting the second cover 12 to a closed state to achieve uniform compression of the seal 24 along its circumference. Uniform compression of the seal 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com