Dsm enabling of electro mechanically controlled refrigeration systems

a technology of electromechanical control and refrigeration system, applied in the field of energy management, can solve the problems affecting the efficiency of household refrigeration appliances, etc., and achieve the effect of reducing the power consumption of electromechanically controlled refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

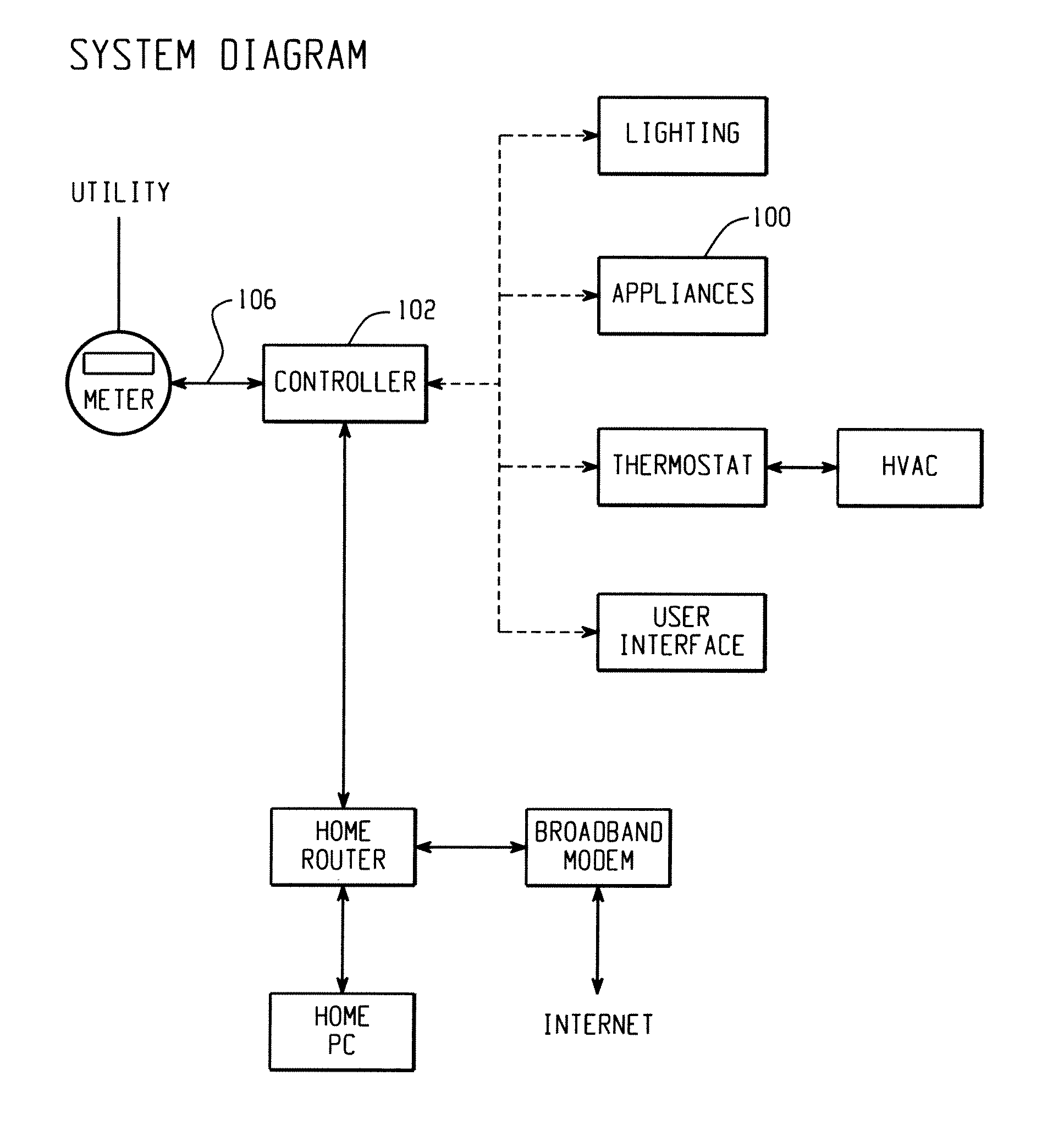

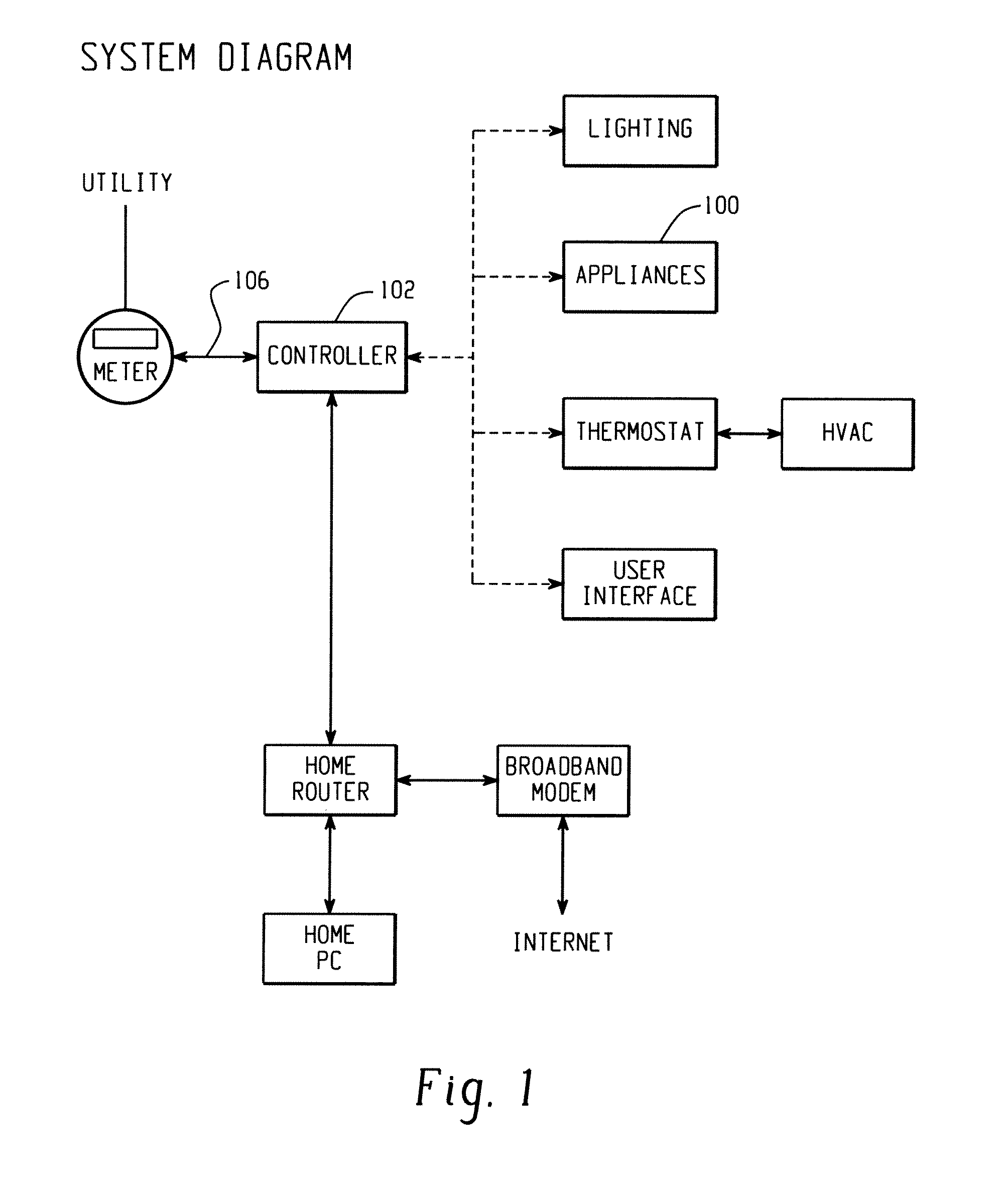

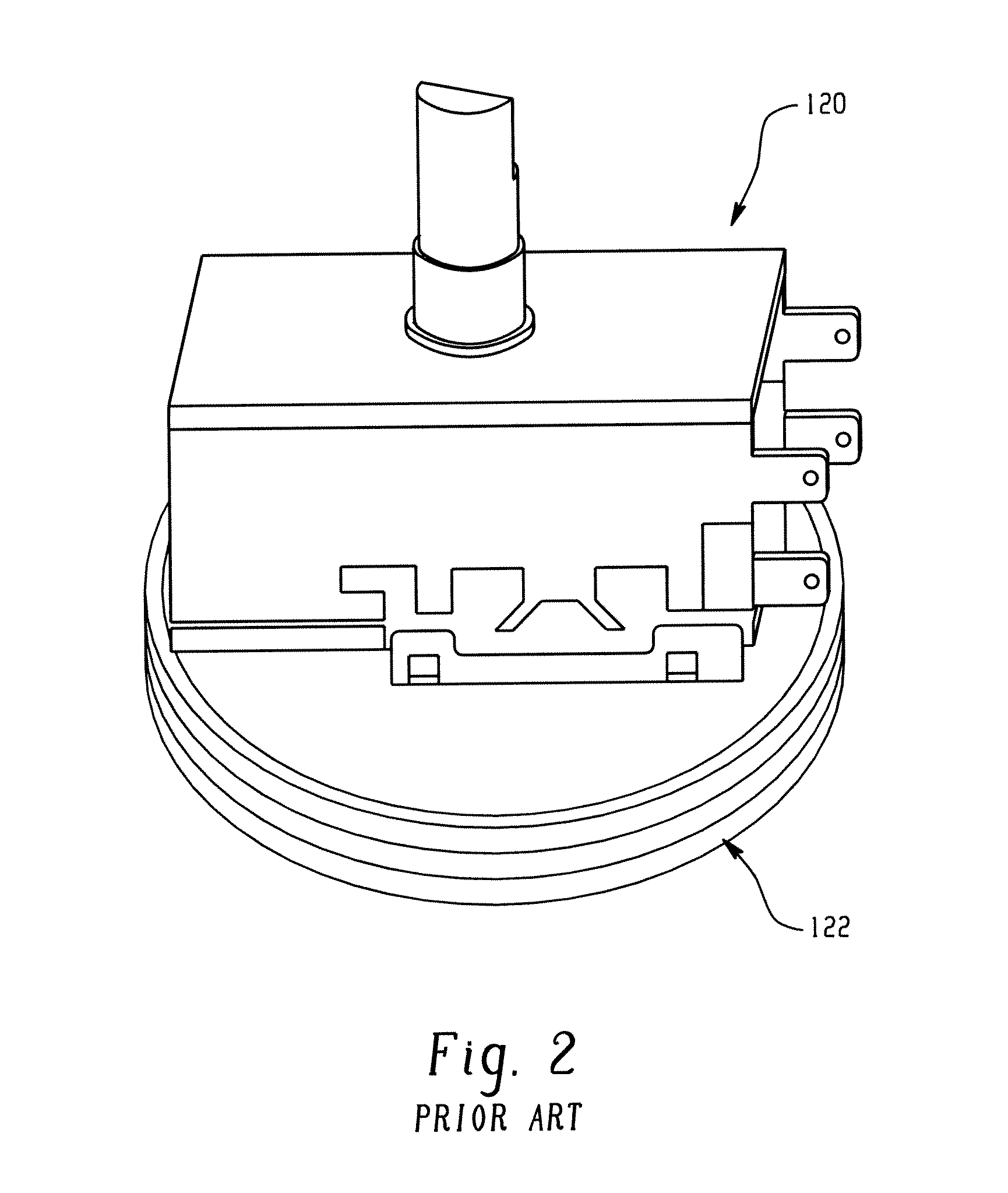

[0021]An exemplary embodiment of an energy management system for household appliances 100 is illustrated in FIG. 1. An electronic controller 102 is provided for communicating with a utility meter and reducing power consumption in response to a signal 106 indicative of a peak demand period. Electromechanically controlled refrigerators, according to one aspect of the present disclosure, include a cold control 120 to control the temperature of the refrigerator compartments, which is depicted in FIG. 2. A cold control 120 is a temperature control incorporating a single pole, single throw switch with an associated set of electrical contacts for turning a refrigerator's compressor and fans concurrently on and off. A bourdon tube 122 is associated with the cold control 120 to sense temperature increases and decreases in a refrigerator compartment. As introduced above, a bourdon tube 122 is a hollow tube filled with refrigerant or an inert gas and placed in the airstream of the compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com