Headlight optical axis adjustment device

a technology of optical axis and adjustment device, which is applied in the direction of lighting support device, transportation and packaging, lighting and heating apparatus, etc., can solve the problems of inability to adjust the pitch angle of the vehicle finely, inhibit durability, and confuse the drivers of oncoming vehicles, etc., to achieve unnecessary adjustment and enhance durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

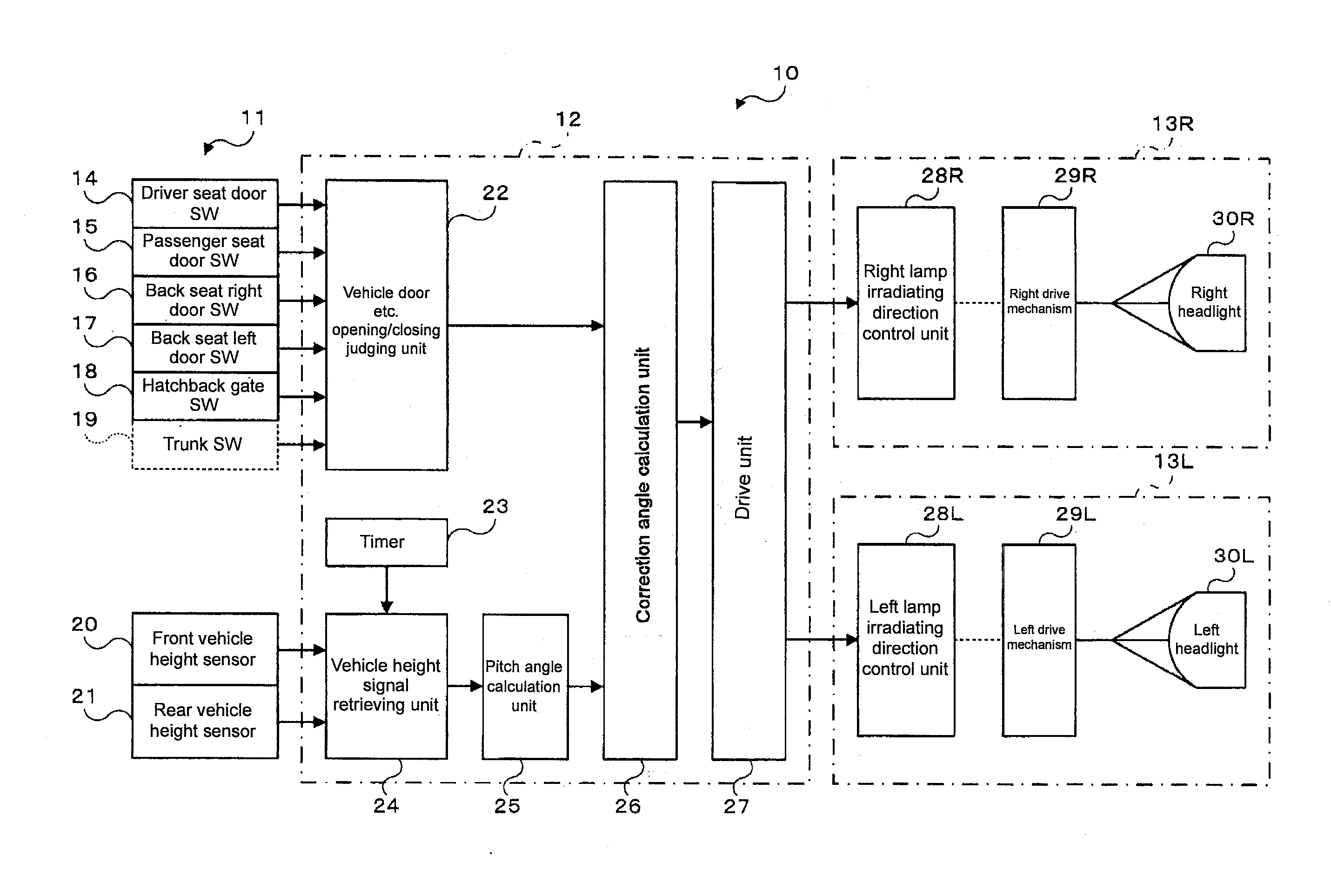

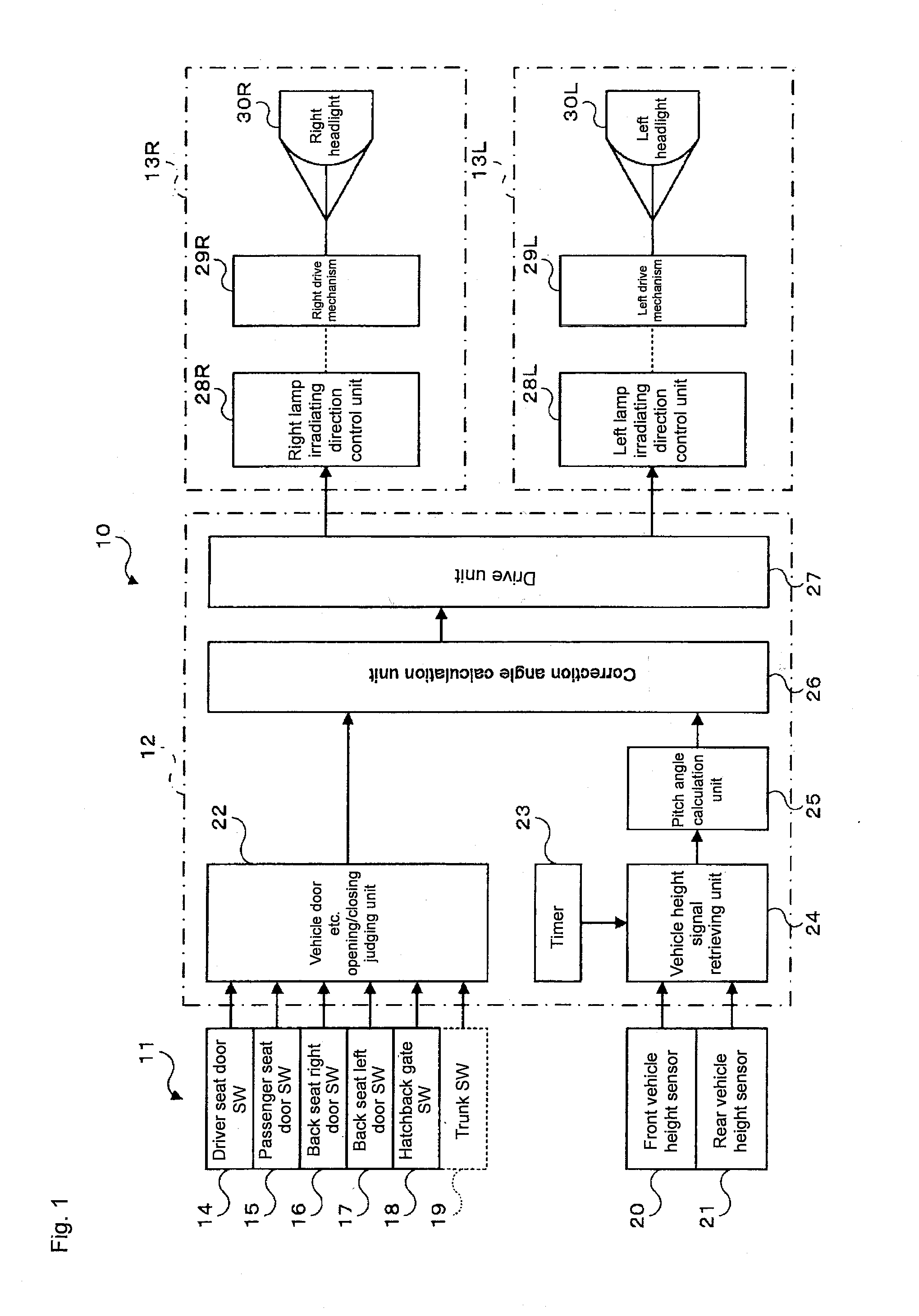

Method used

Image

Examples

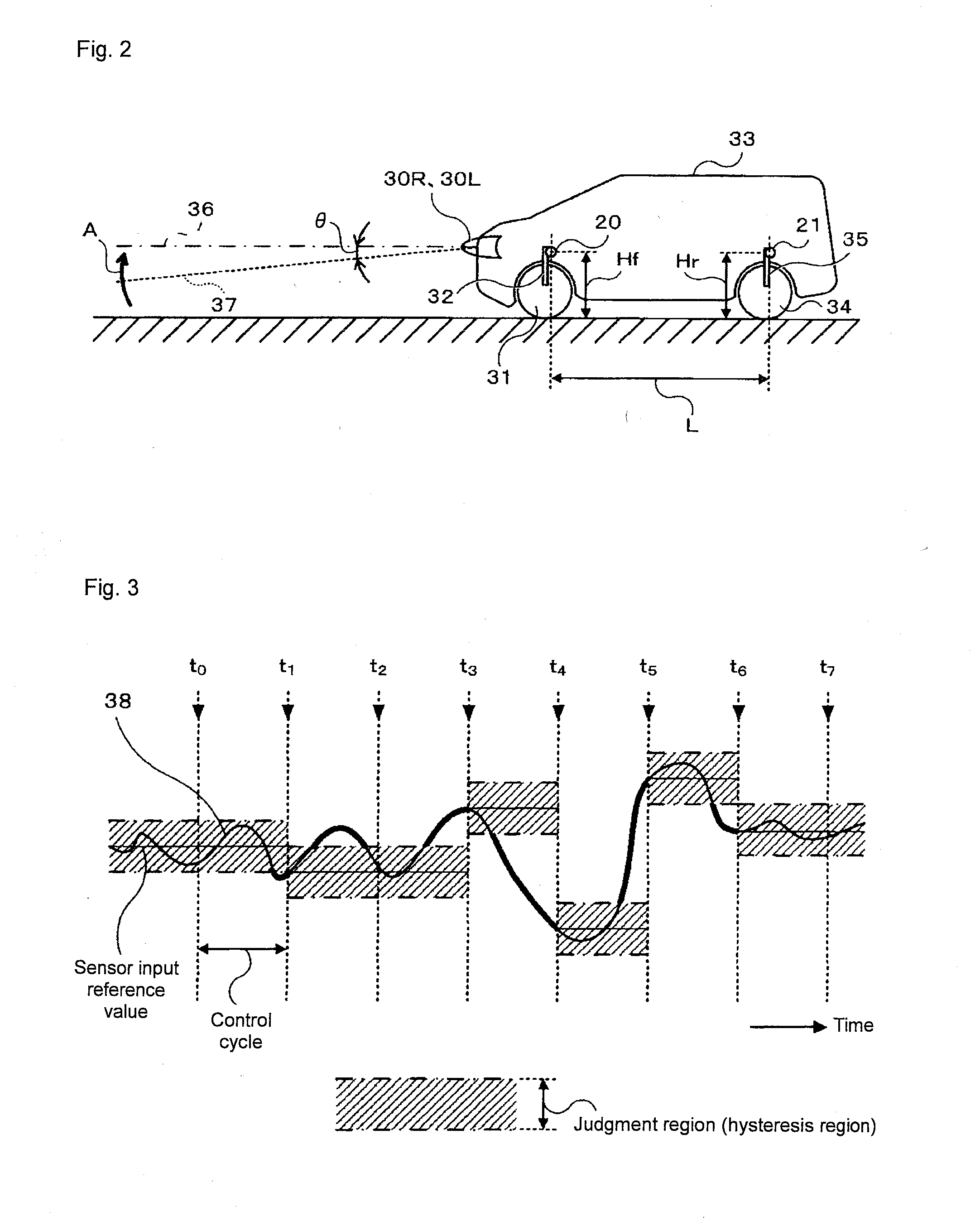

first example

[0056]FIG. 4 shows a view of an operation flow in a first example. In this example, the opening / closing of the doors (driver seat door, passenger seat door, back seat right door, back seat left door, hatching gate, trunk) is judged by the vehicle door etc. opening / closing judging unit 22 (step S11), where when judged that one or more doors is opened (“YES” in step S11), presumption and judgment are made as being in a situation where the passenger goes in / out or the baggage is being loaded / unloaded, and the change in the pitch angle θ generated during the door opened state is calculated from the detection signals (Hf, Hr) of the front vehicle height sensor 20 and the rear vehicle height sensor 21, and the control amount of each drive mechanism (right drive mechanism 29R and left drive mechanism 29L) of the right lamp ASSY 13R and the left lamp ASSY 13L is determined based on the calculation result, so that the optical axes of the right headlight 30R and the left headlight 30L are adj...

second example

[0059]FIG. 5 shows a view of an operation flow in a second example. In this example, the opening / closing of the door (driver seat door, passenger seat door, back seat right door, back seat left door, hatchback gate, trunk) is judged by the vehicle door etc. opening / closing judging unit 22 (step S21), where when judged that one or more doors are opened (“YES” in step S21), presumption and judgment are made as being in a situation where the passenger goes in / out or the baggage is being loaded / unloaded, and the optical axes of the right headlight 30R and the left headlight 30L are adjusted to “lower side” (preferably lowermost side) (step S22).

[0060]Herein, adjusting the optical axis to “lower side” means the following. Each drive mechanism (right drive mechanism 29R and left drive mechanism 29L) of the right lamp ASSY 13R and the left lamp ASSY 13L moves the optical axis (accurately, tilt angle of reflector) of the right headlight 30R and the left headlight 30L, but the movement amoun...

third example

[0062]FIG. 6 shows a view of an operation flow in a third example. In this example, the opening / closing of the doors (driver seat door, passenger seat door, back seat right door, back seat left door, hatching gate, trunk) is judged by the vehicle door etc. opening / closing judging unit 22 (step S31), where when judged that one or more doors are opened (“YES” in step S31), presumption and judgment are made as being in a situation where the passenger goes in / out or the baggage is being loaded / unloaded, and only the lower side control of the optical axis of the headlight is permitted (step S33) only when both or one of the detection signals (Hf, Hr) of the front vehicle height sensor 20 and the rear vehicle height sensor 21 exceeds the judgment region (hysteresis region: Hopen herein) of predetermined upper and lower widths (step S32), and the optical axes of the right headlight 30R and the left headlight 30L are adjusted (step S34).

[0063]In step S33, the reason for “permitting only the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com