Integrated Bottle, Case and Mirror

a technology for mirrors and bottles, applied in rigid containers, transportation and packaging, packaging, etc., can solve the problems of affecting the use of lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

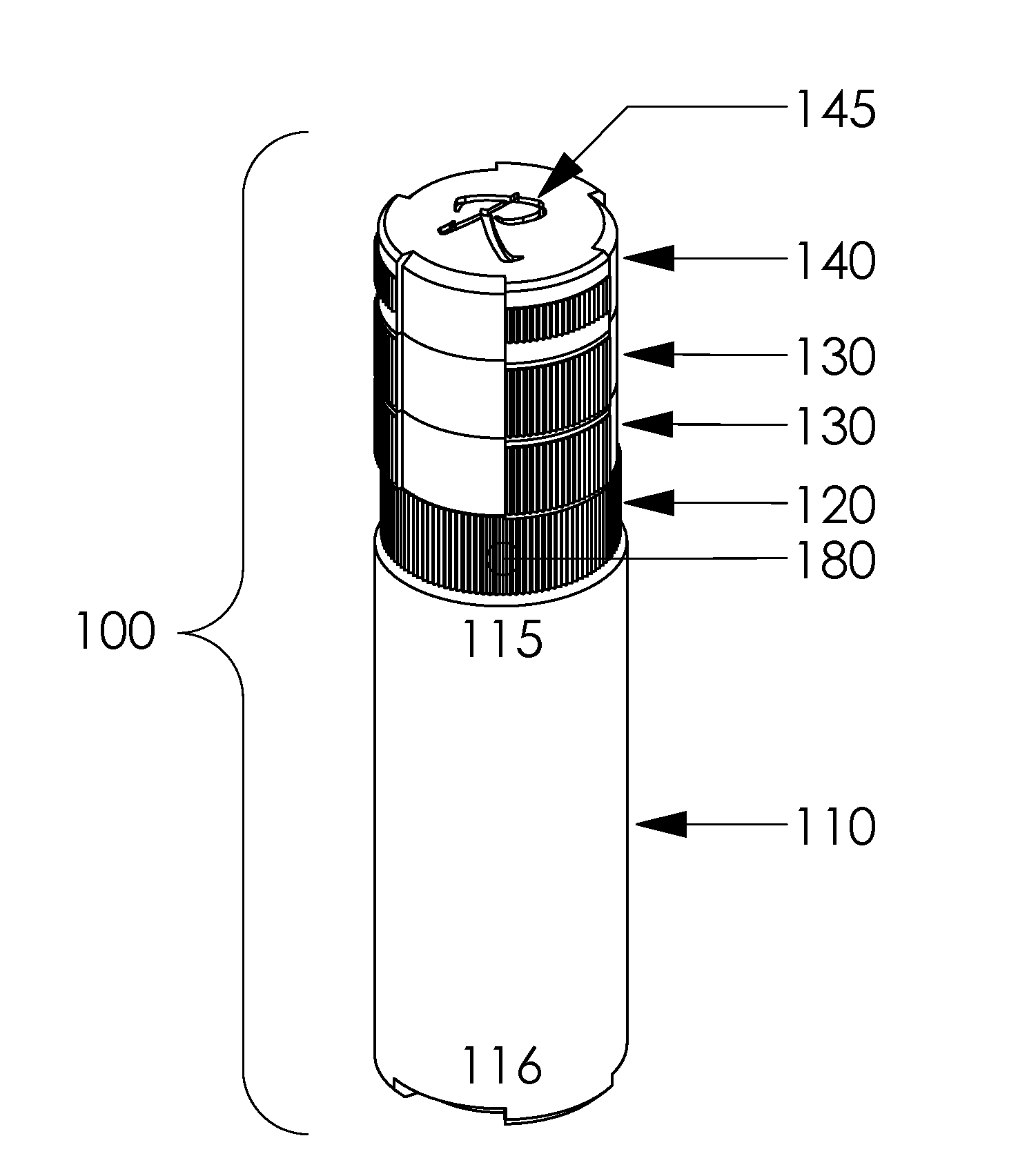

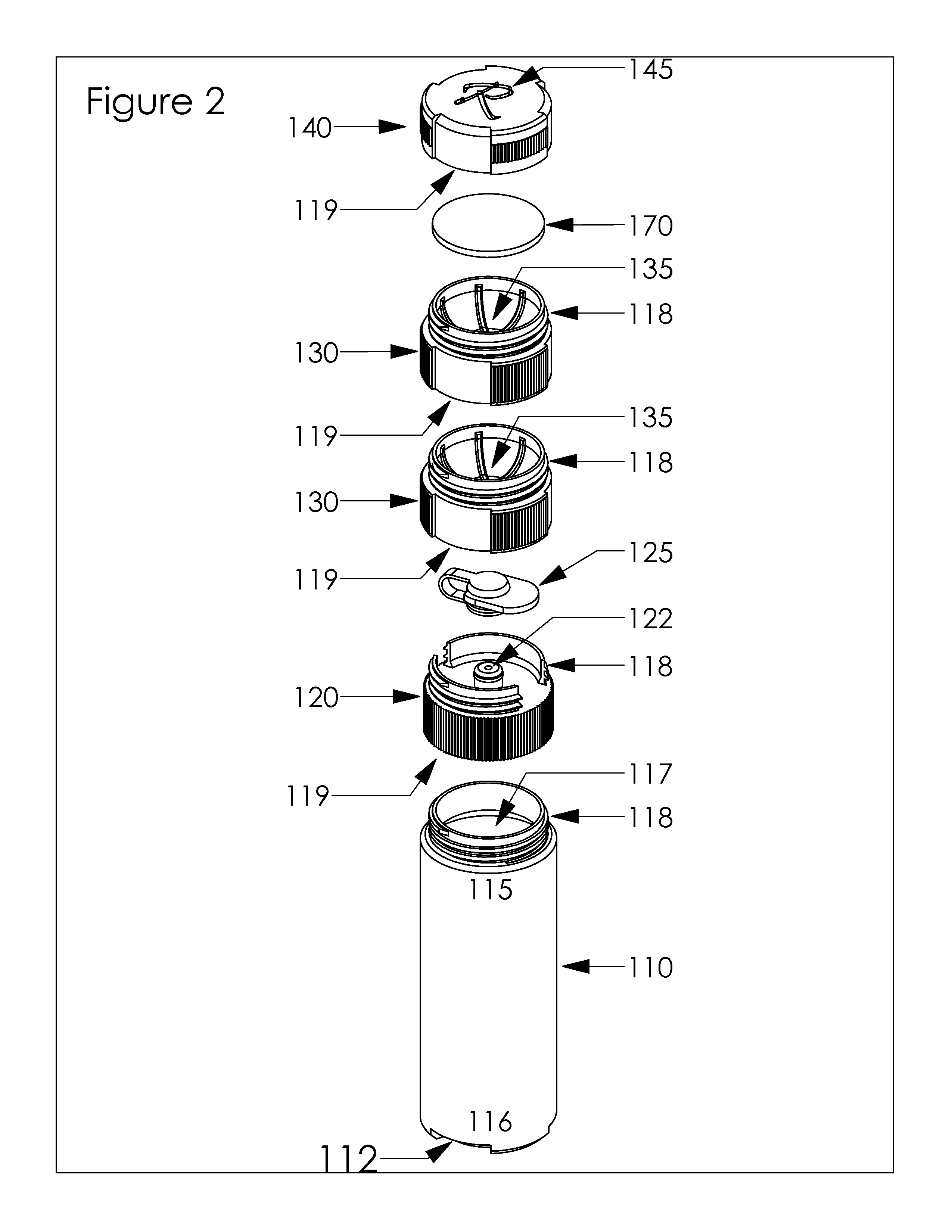

[0085]Referring to the figures, FIGS. 1-6 show one embodiment of a device in accordance with the principles of the present invention in multiple positions and configurations. FIG. 1 shows a perspective view of a device 100 in an integrated (stacked or assembled) configuration or position comprising one bottle 110, one bottle cap 120 (nozzle lid not shown), two contact lens cases 130, and one cover 140 (mirror within the cover not shown). As shown in FIGS. 2-6, the top end 115 of bottle 110 includes an opening or aperture 117 and a male connector 118 with threads or other fastening means such as, for example, a snap fit connector, for secure but removable attachment of bottle cap 120 to bottle 110. The bottom 112 of bottle 110 is substantially flat for stability when bottle 110 is placed on a flat surface such as, for example, a table or counter. Preferably, bottle 110 is cylindrical or tubular to hold a fluid inside. Materials of construction for bottle 110 include those known in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com