Extracting and cooling system for large flows of heavy ashes with efficiency increase

a technology of large flows and cooling systems, applied in the direction of combustible gas production, lighting and heating apparatus, combustion process, etc., can solve the problems of high implementation and handling costs, known cooling systems that cannot be effective and efficient, and high production of heavy ashes in high-power boilers. , to achieve the effect of increasing the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

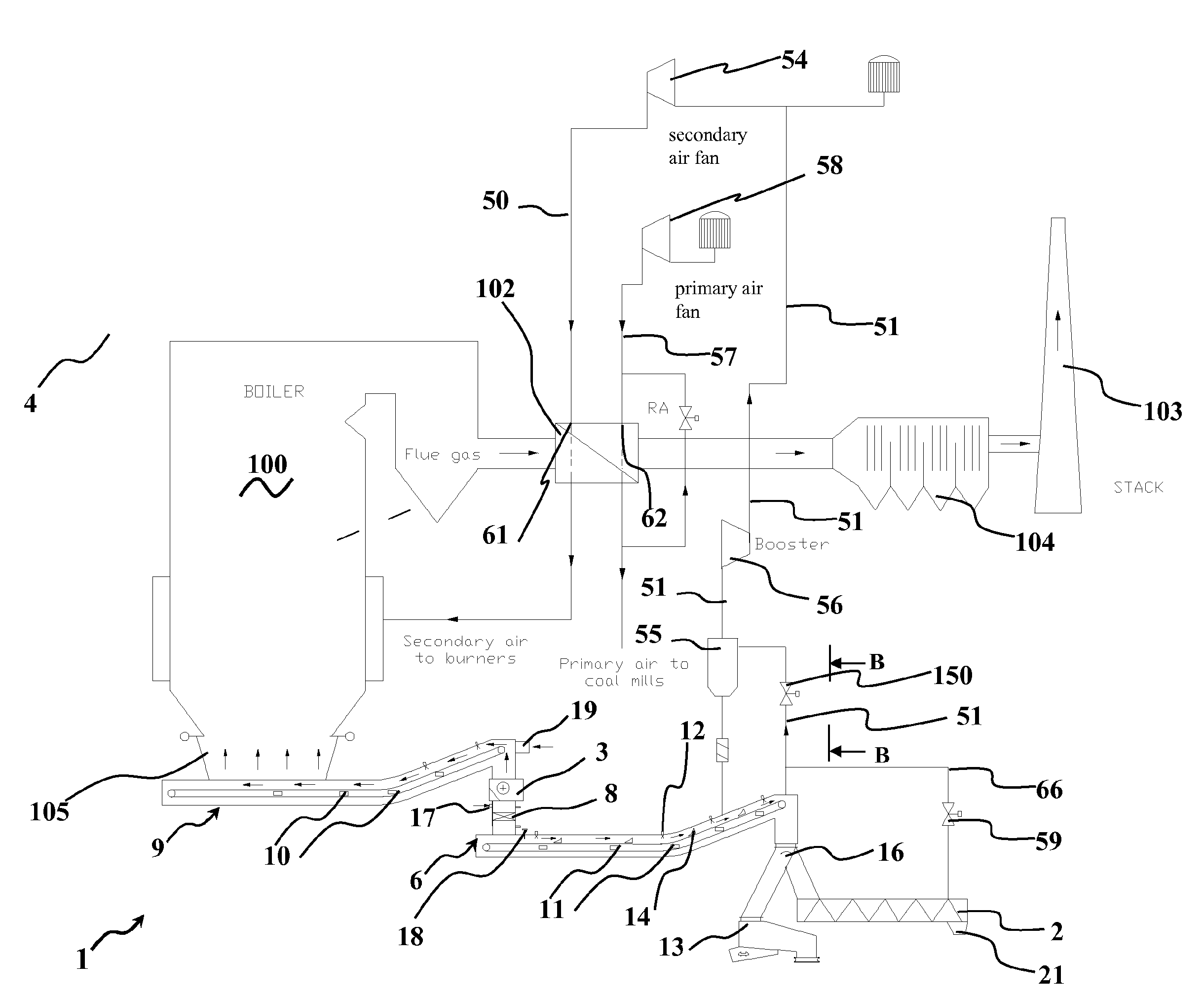

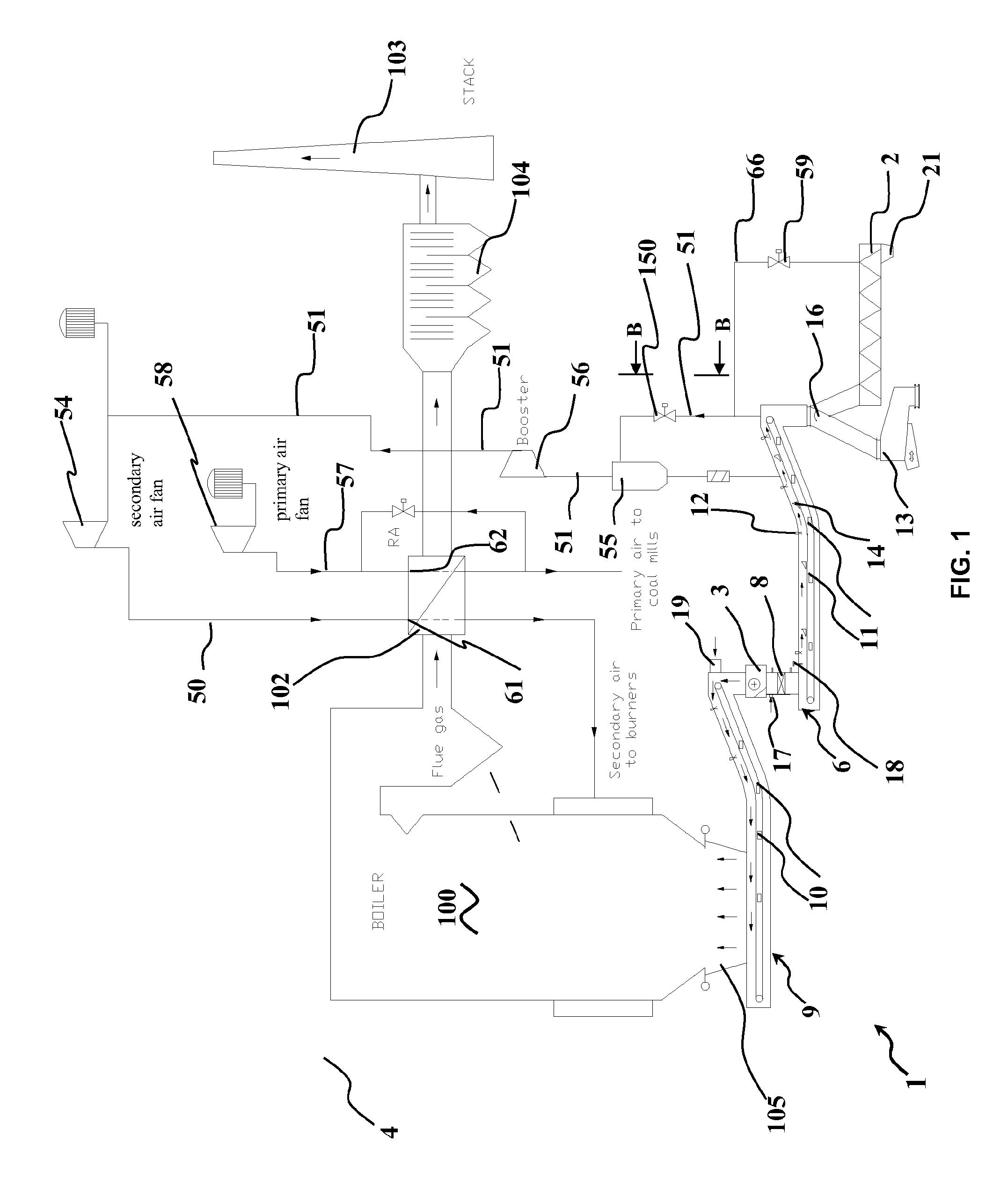

[0044]By referring to the above-mentioned figures, a plant for extracting and cooling the combustion residues, of the type used for example in solid fossil fuel thermo-electric plants and according to a preferred embodiment of the invention, is designated as a whole with 1. As it will be better appreciated in the following description, the plant 1 is particularly suitable to handle large flows of heavy ashes, produced for example by the combustion of coals or lignites with high ash content.

[0045]For a better explanation clarity, the different components of the plant 1 will be described as follows by referring to the path followed by the combustion residues as from the extraction thereof from the bottom of the combustion chamber (or boiler), designated with 100, until the disposal thereof.

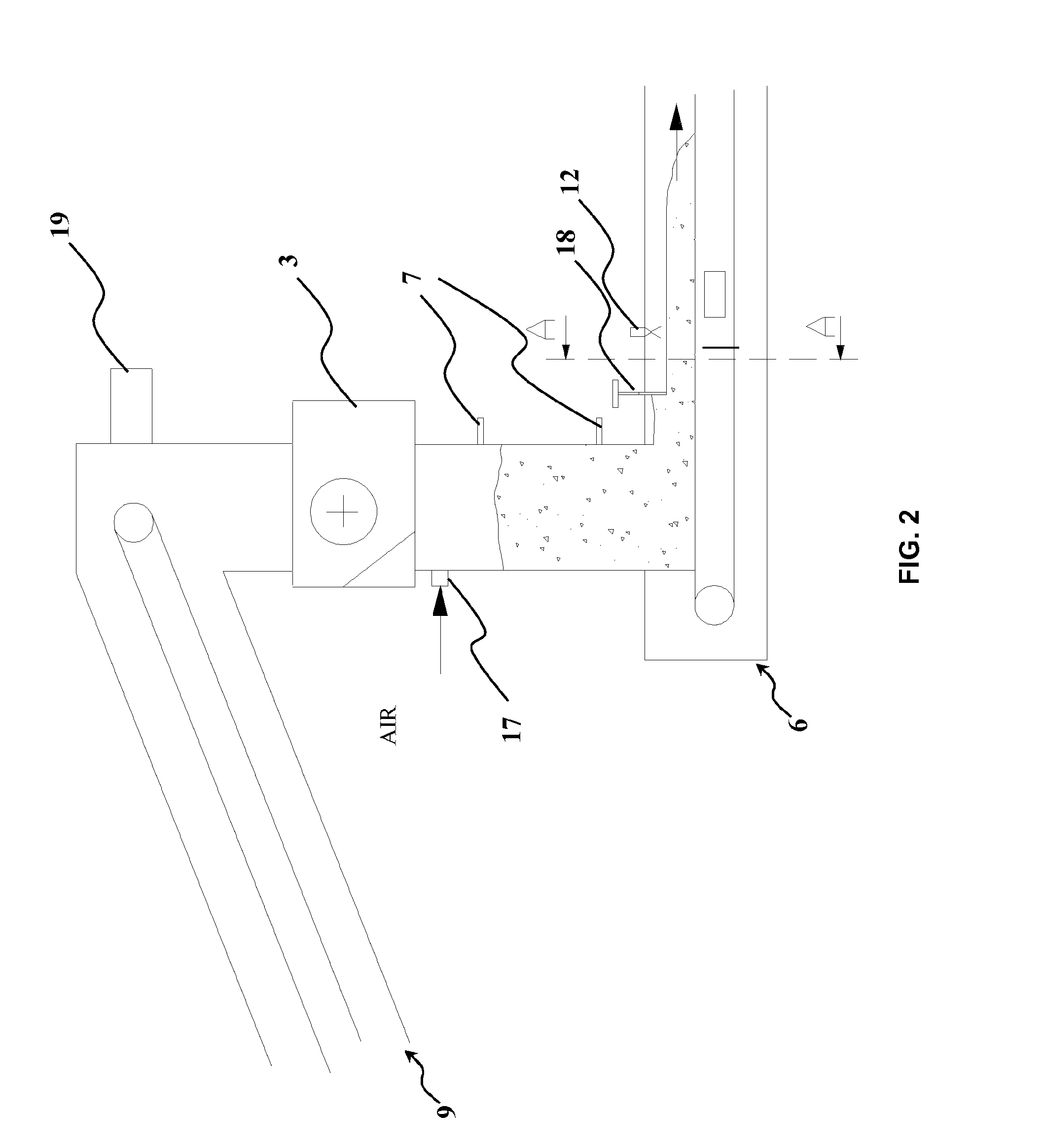

[0046]Immediately downstream of the combustion chamber 100, or better of a transition hopper 105 of the latter, the plant 1 provides a first extraction and transport unit, in particular a dry extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com