Circulating Fluidized Bed Combustor and a Method of Operating a Circulating Fluidized Bed Combustor

a fluidized bed and combustor technology, applied in the direction of lighting and heating apparatus, emission prevention, combustion types, etc., can solve the problems of large ash particles in the cfb system, high dust loading, etc., and achieve the effect of reducing the amount of pollutants in the atmospher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

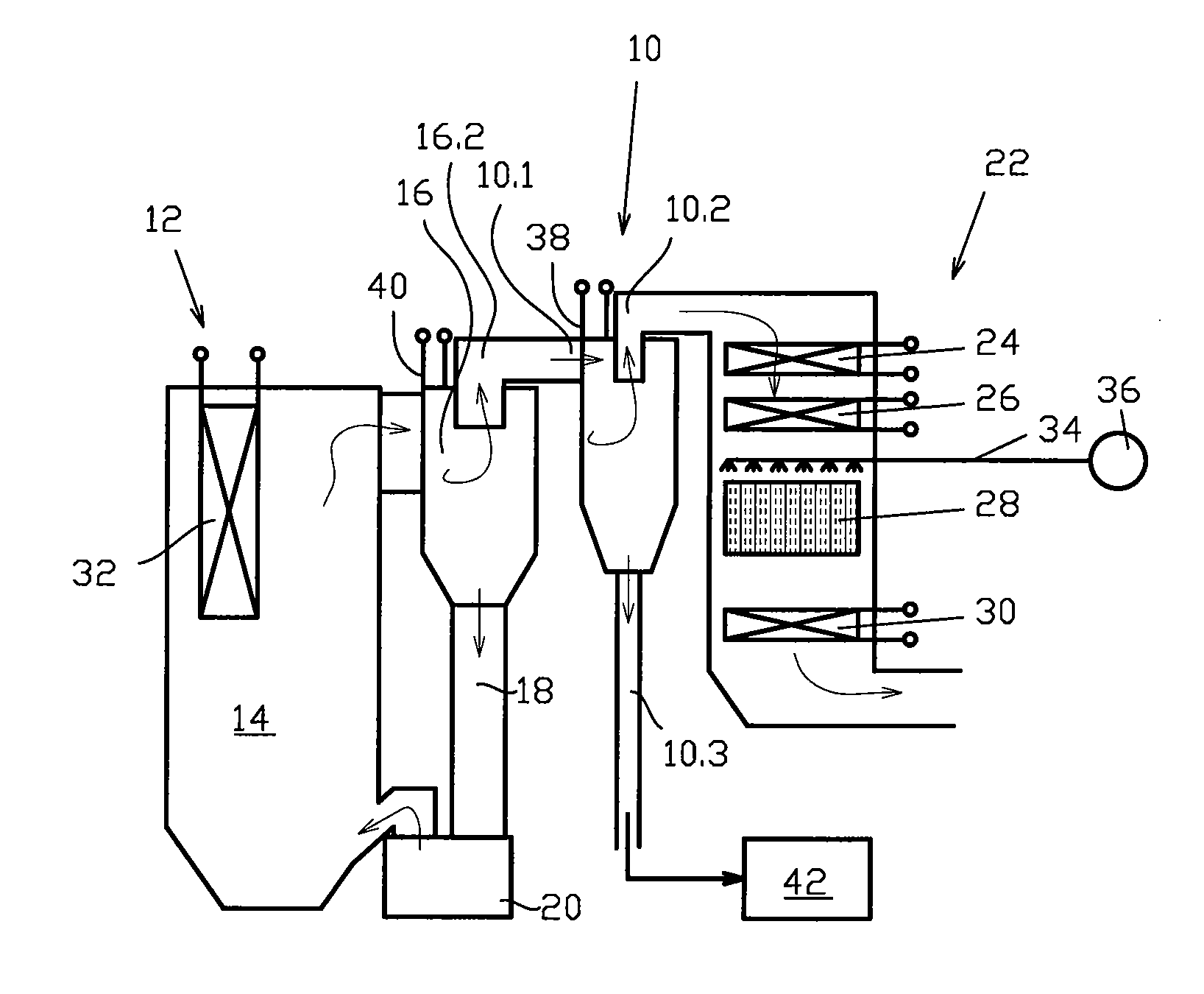

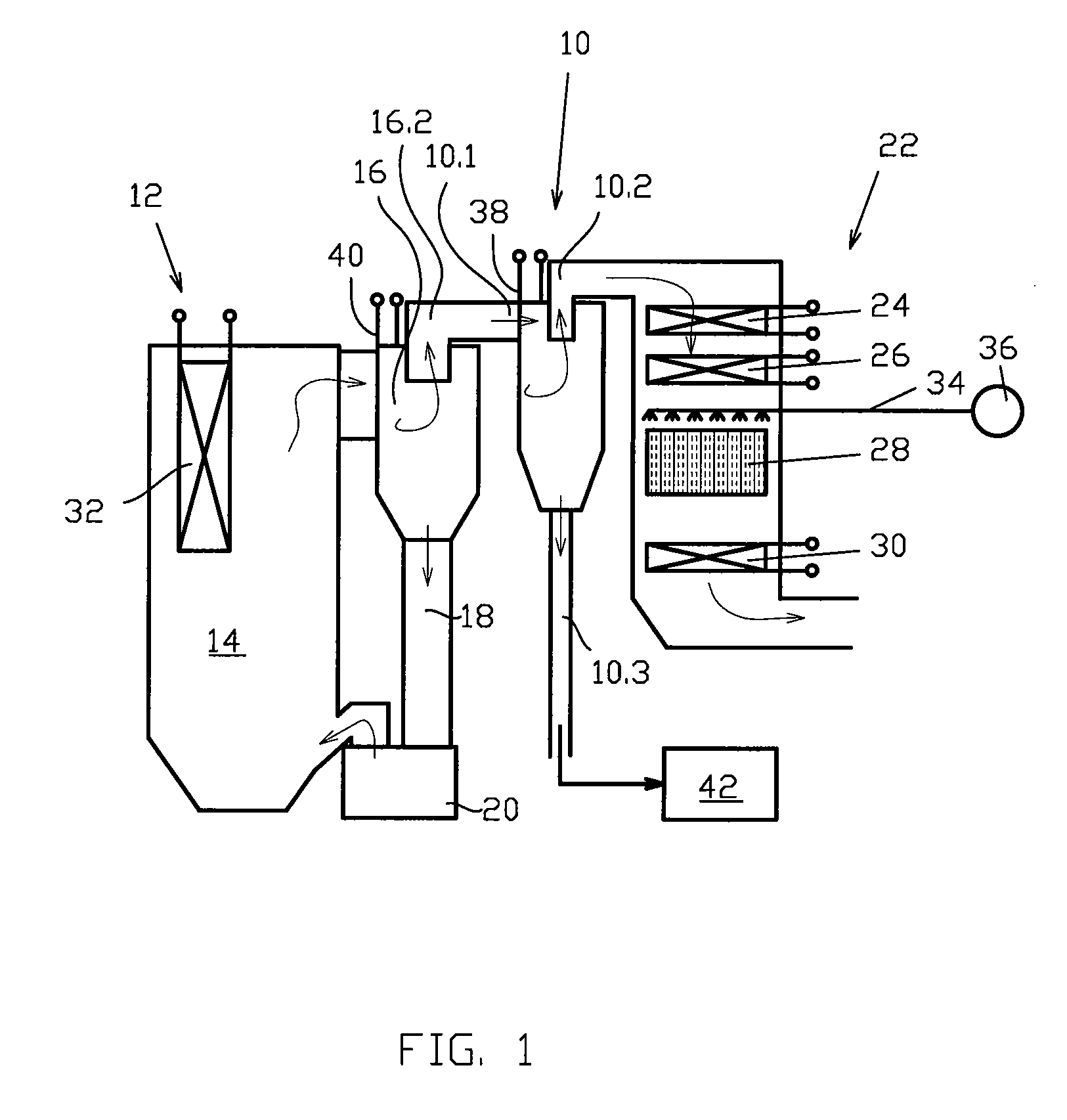

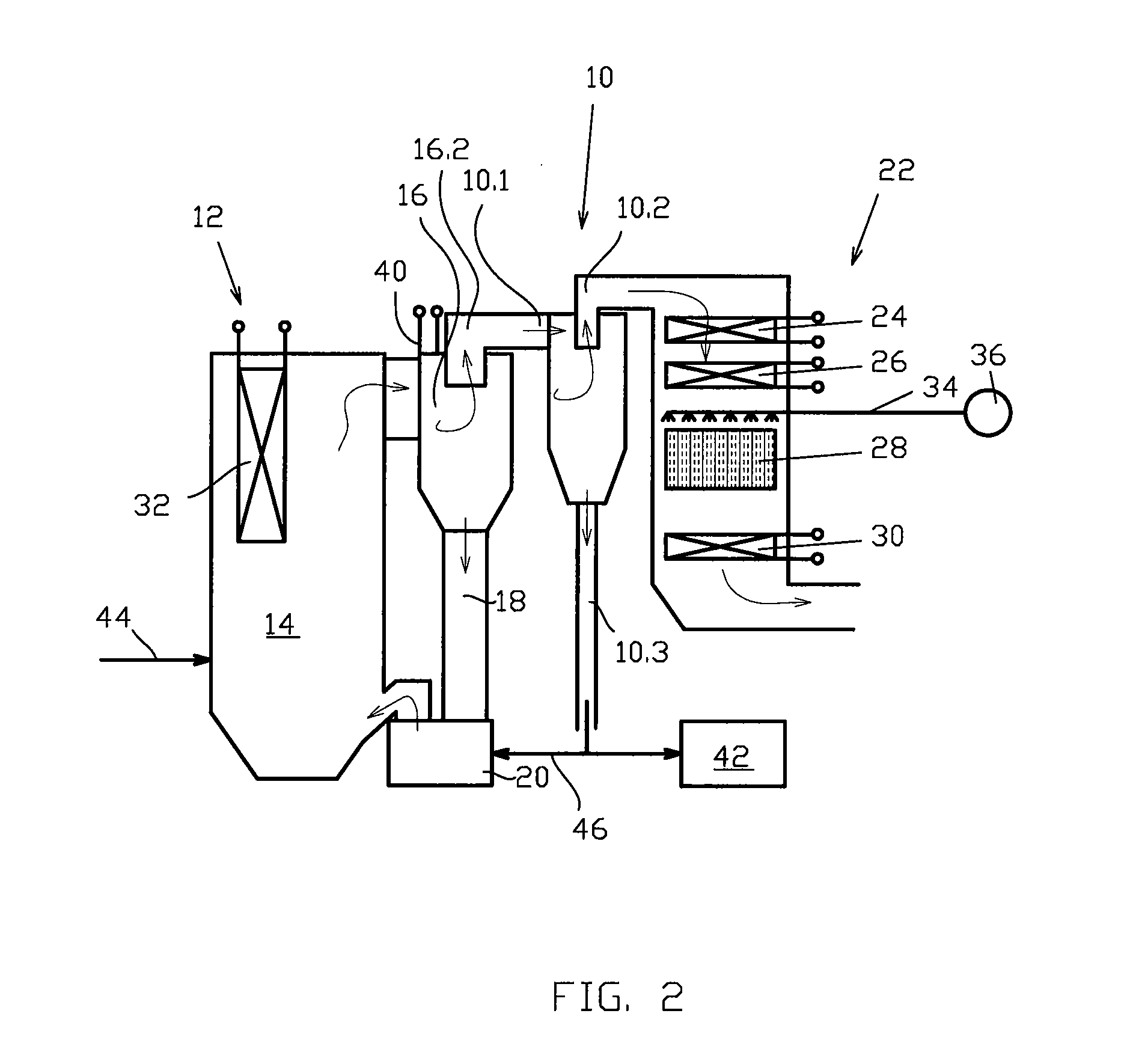

[0057]FIG. 1 schematically illustrates a circulating fluidized bed (CFB) combustor arrangement 10. The CFB combustor arrangement 10 comprises a circulating fluidized bed reactor 12 including a combustion chamber 14, in which fuel material may be combusted making use of a circulating bed of solid particles therein. The CFB reactor 12 is provided with numerous auxiliary devices, of which only those necessary for understanding the invention are described herein. The CFB reactor is connected at its upper portion to a cyclone separator arrangement 16, which acts as a primary separation stage. In the embodiment of FIG. 1, the cyclone separator arrangement 16 includes one cyclone separator, but, e.g., in larger CFB reactors, there may be several separators installed in parallel. The cyclone separator 16 is connected to the lower portion of the combustion chamber 14 via a return conduit 18, including a sealing device, like a loop seal, the purpose of which is, e.g., to prevent gas flow from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com