Air movement system

a technology of air movement and air flow, which is applied in the direction of positive displacement liquid engines, instruments, machines/engines, etc., can solve the problems of unnecessarily increasing the cost of both the system and its operation, affecting the air flow of the system, and affecting the operation of the system, etc., to achieve the effect of improving the air movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

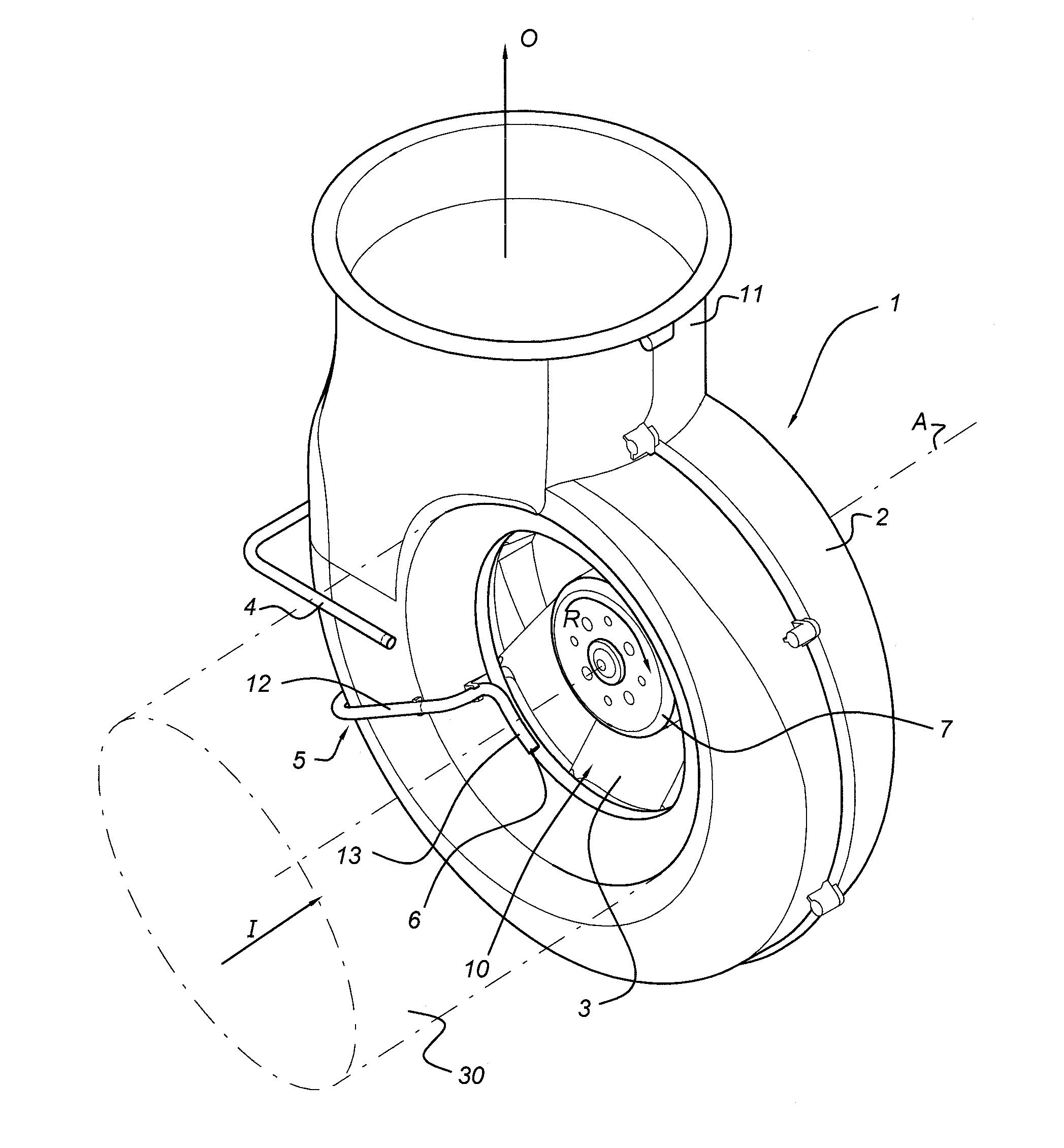

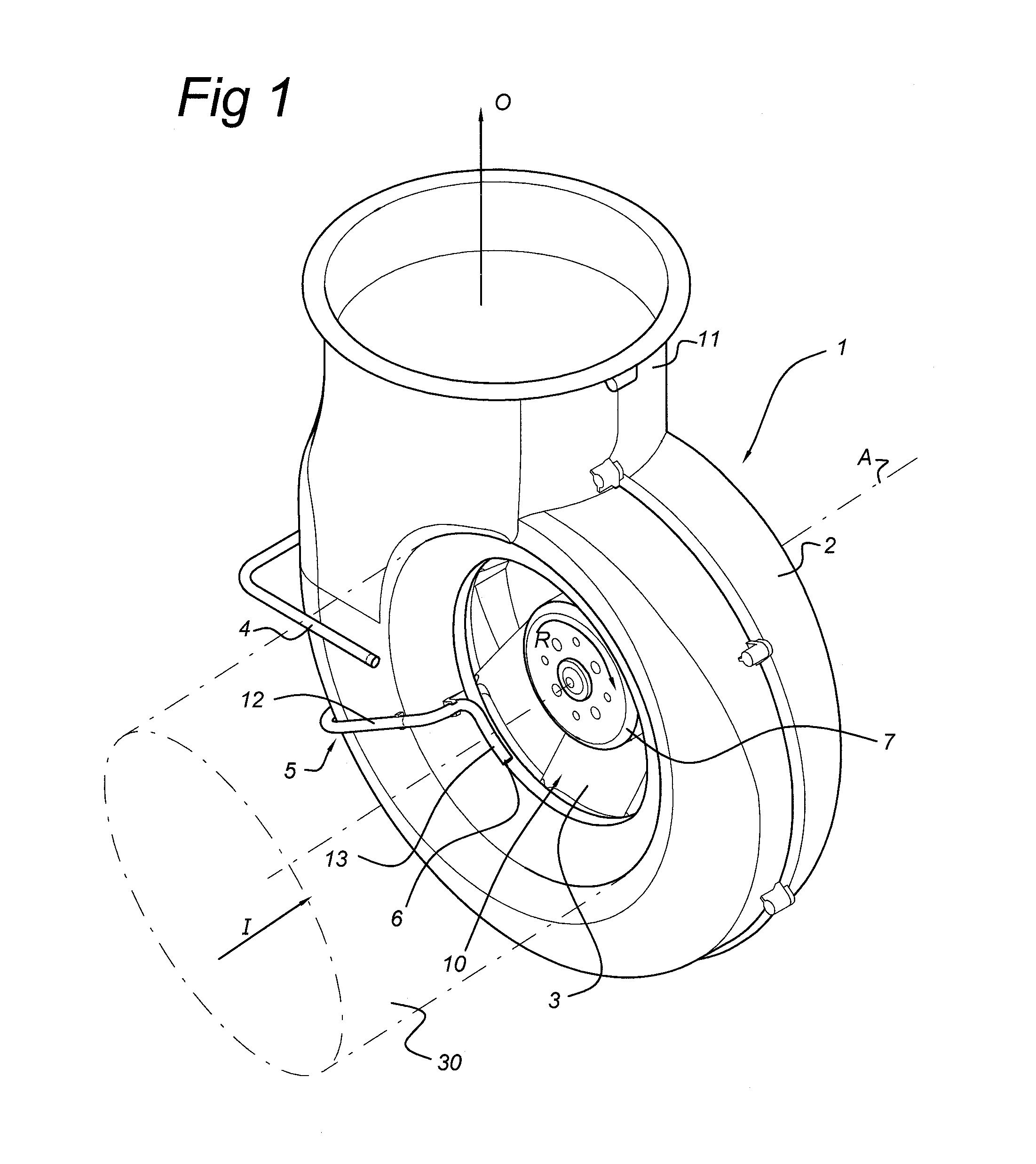

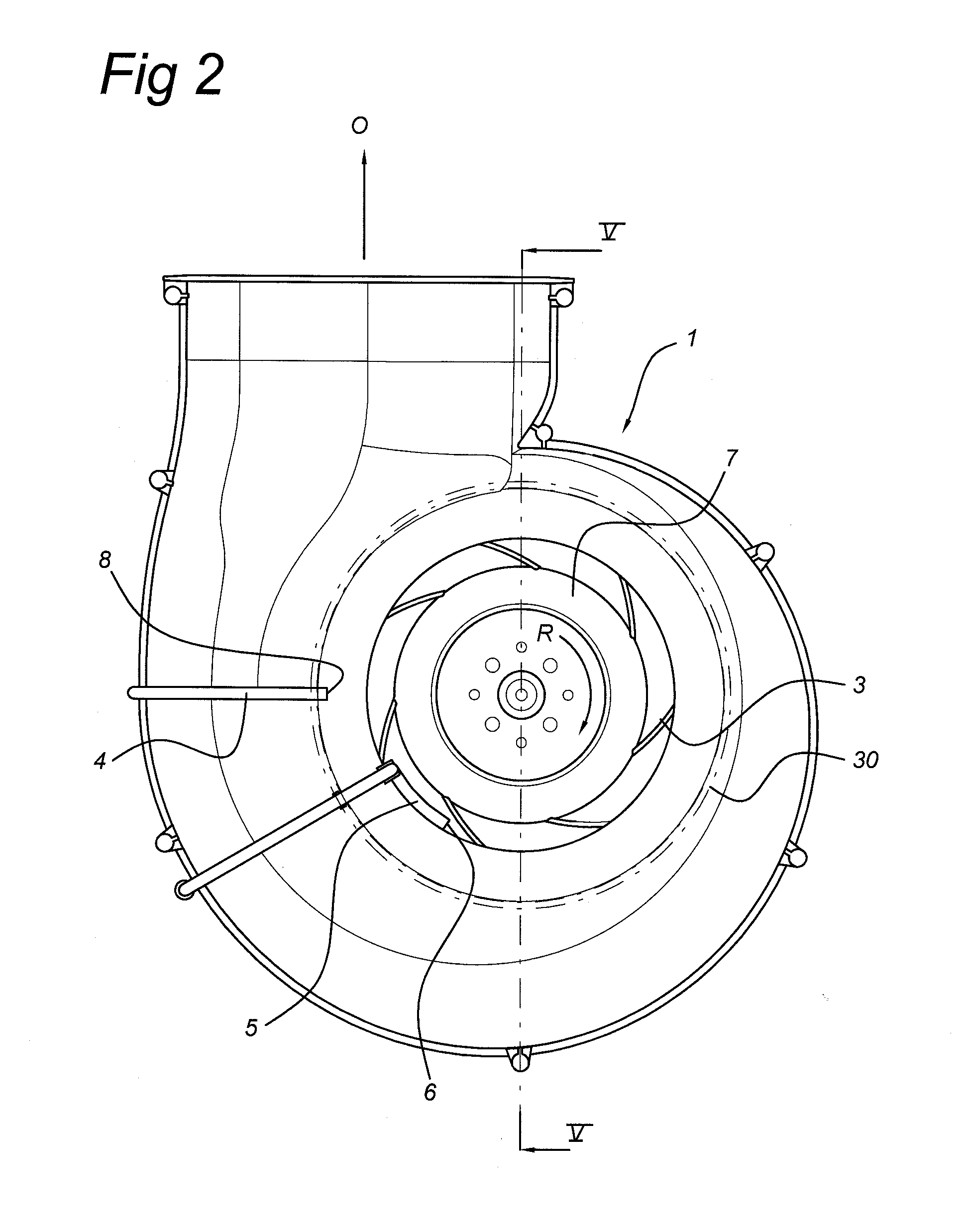

[0043]Example FIG. 1 shows a perspective view of centrifugal pump 1 with a centrifugal fan unit. Example FIGS. 2-4 show several views of the centrifugal pump shown in example FIG. 1. Example FIG. 5 shows a cross section of the centrifugal pump indicated in example FIG. 2.

[0044]Centrifugal pump 1 has a spiral or annular casing 2. Spiral casing or house 2 defines part of inlet duct 10. The direction of incoming air is indicated by arrow I. Example FIGS. 3 and 4 also provide views of the air flow direction I of the incoming air. Provided at the smallest cross-section of inlet duct 10 is fan 3. As illustrated in example FIG. 2, when fan 3 is in operation, its rotational direction is clockwise as indicated by arrow R. House 2 further defines outlet 11. The direction of the outgoing air at outlet 11 is indicated by arrow O. Example FIGS. 2 and 4 also provide views of the air flow direction O of the outgoing air. The direction of outgoing air O is perpendicular to the direction of incoming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com