Arrangement for axially securing rotating blades in arotor, and gas turbine having such an arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

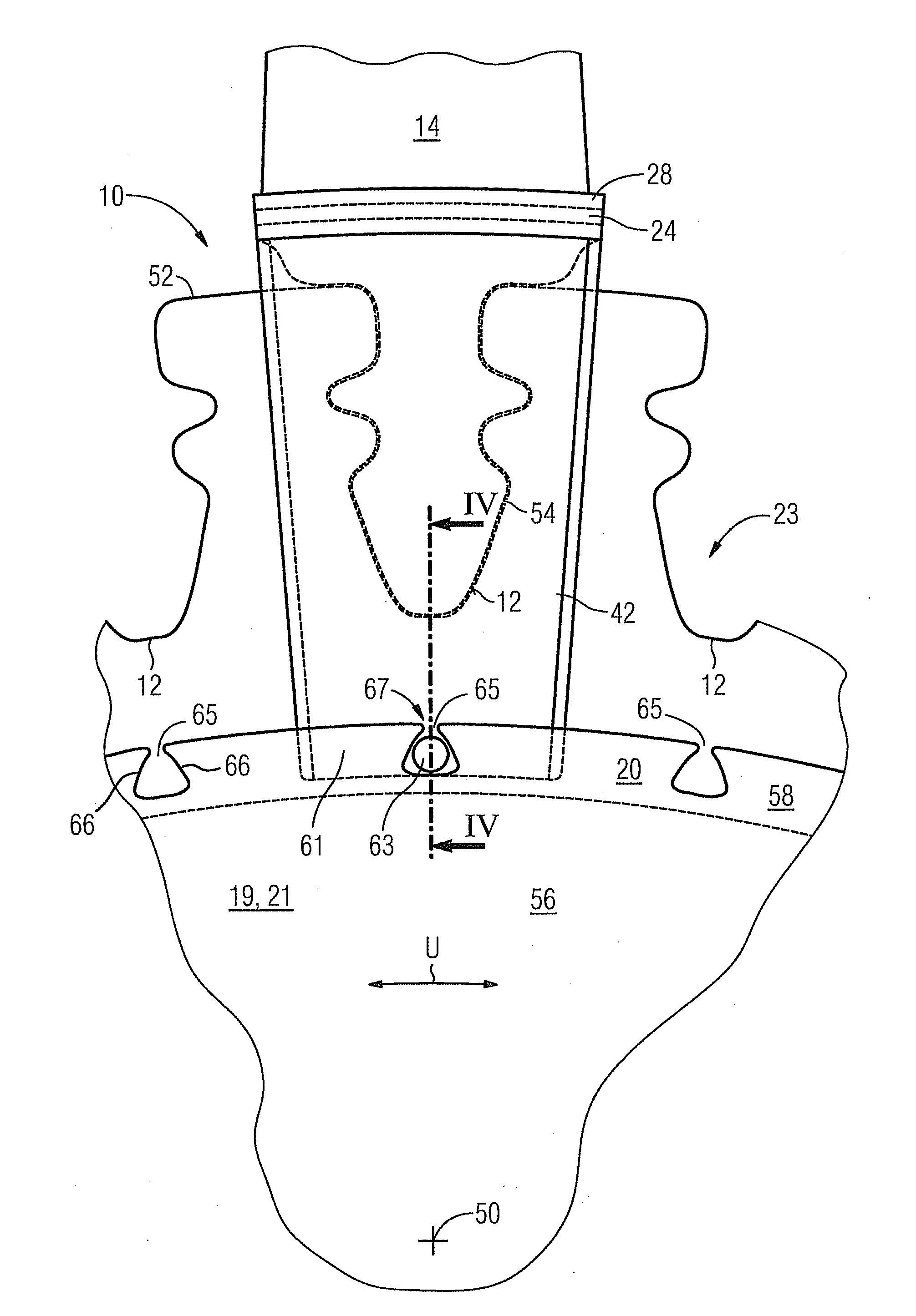

[0025]FIG. 3 shows a detail of the end-face plan view of the shaft collar 21, which is formed by a rotor disk 19, of a rotor 23 of a gas turbine. The rotor 23, which is rotatable around the rotational axis 50, has rotor blade retaining slots 12 which are distributed on its outer periphery 52 along the circumference U and extend in the axial direction, into which slots a rotor blade 14, with a blade root 54 which is constructed corresponding to the rotor blade retaining slot 12, in each case can be inserted. A rotor blade 14 is already inserted in the rotor blade retaining slot 12 which is shown in the middle in FIG. 3. As in the case of the prior art which is shown in FIG. 1 and FIG. 2, a projection 58 or widening, with a radially outwardly open encompassing slot 20 therein, which extends in the axial direction, is arranged on an end face of the rotor disk 19 or on an end-face side surface 56 of the shaft collar 21. The encompassing slot 20 for example is arranged radially further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com