Airless thermal regenerator or enhancer with mixer

a technology of airless thermal regenerator and mixer, which is applied in the direction of machines/engines, exhaust treatment electric control, transportation and packaging, etc., can solve the problems of difficult ignition, difficult to produce more hydrocarbons, disadvantageous traditional configuration, etc., and achieve the effect of reducing the size of the fuel droplet and improving the ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

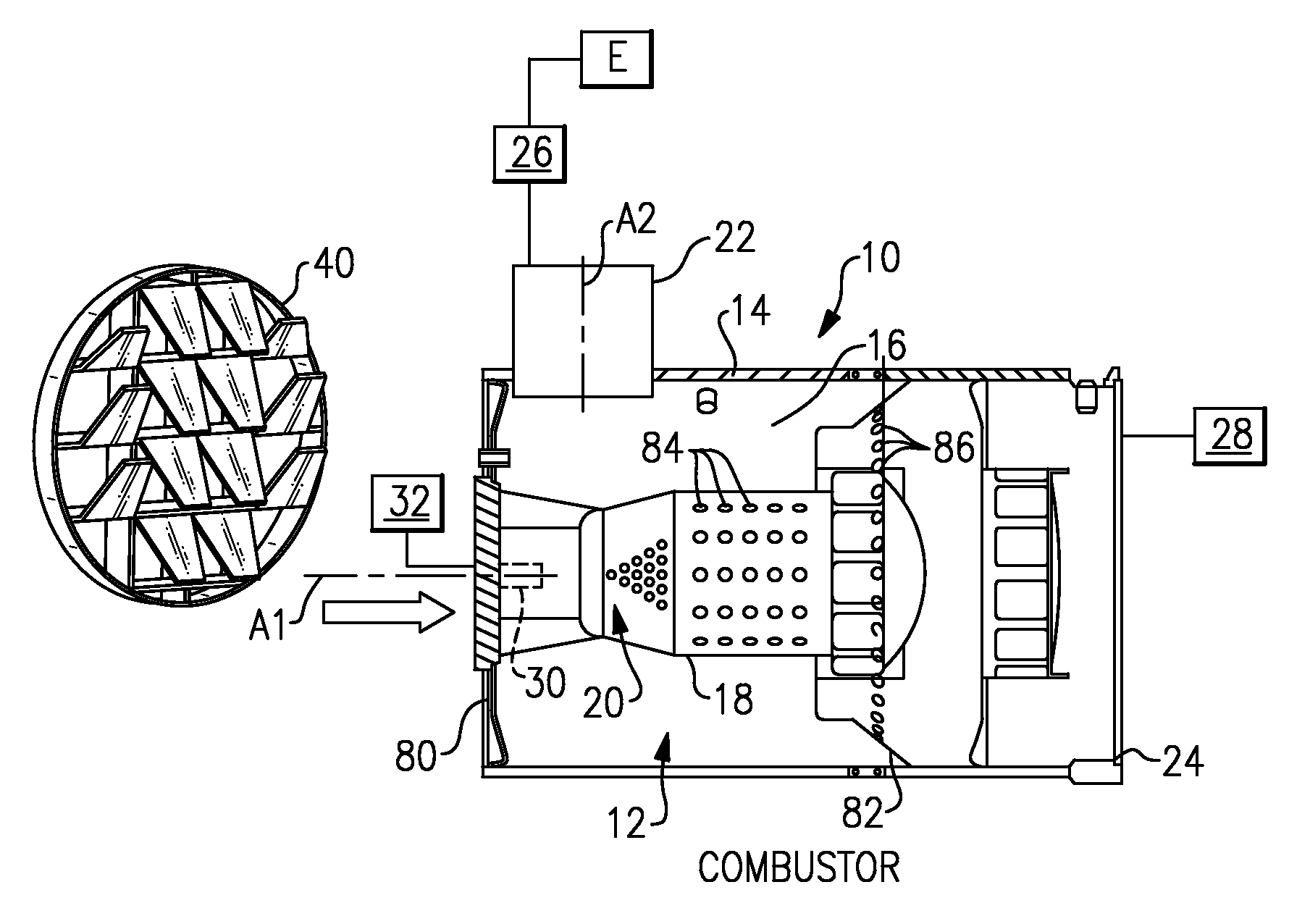

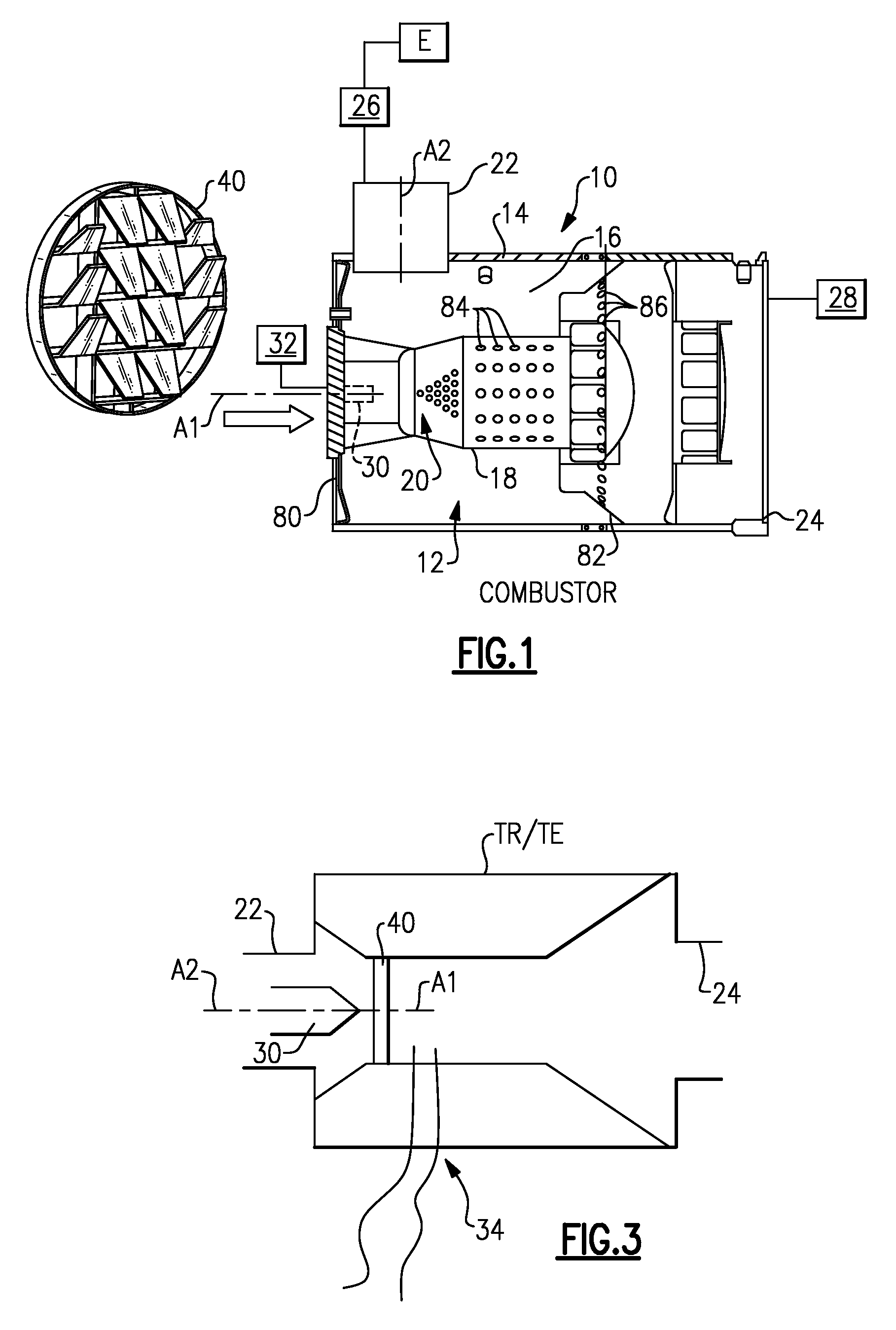

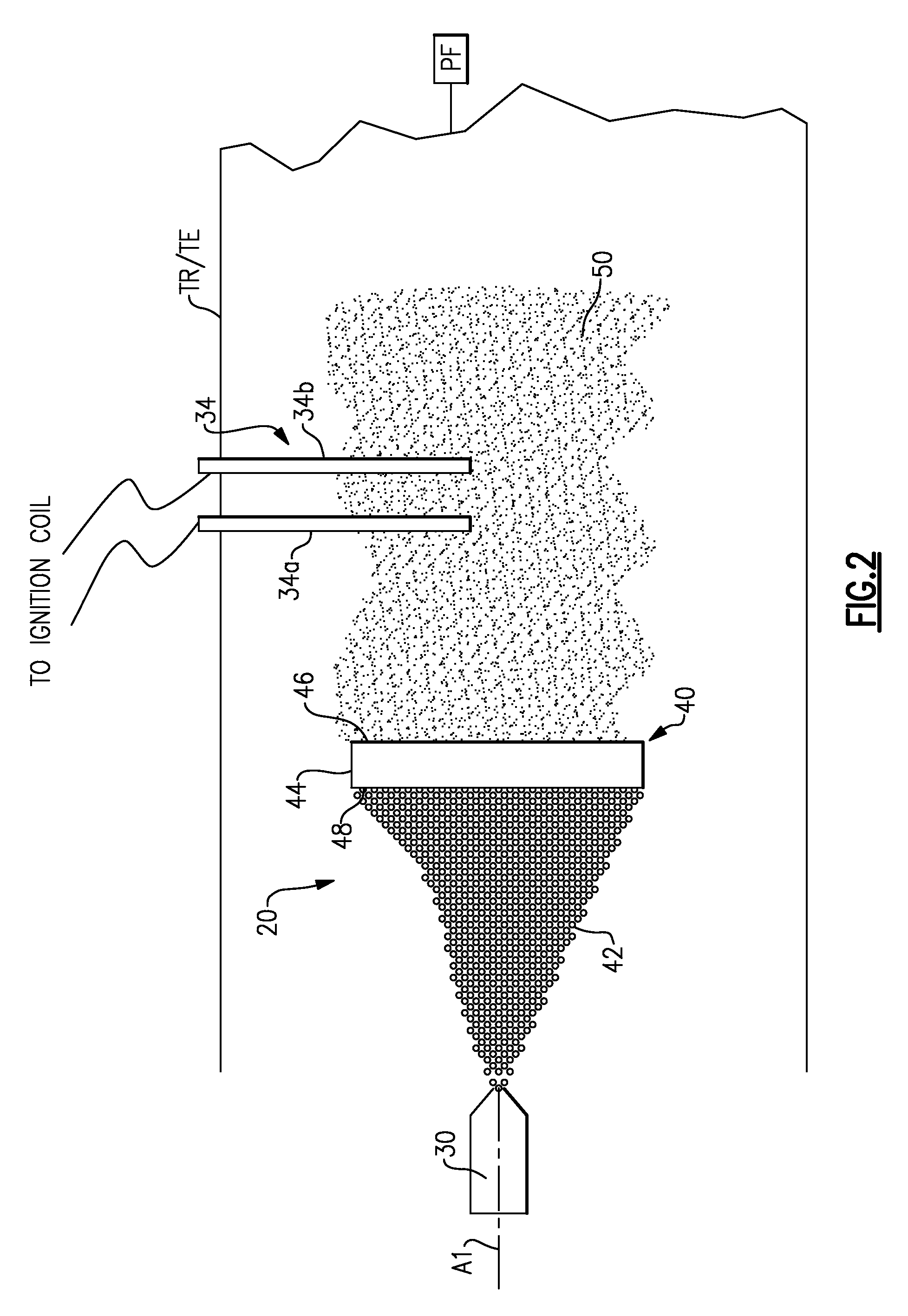

[0014]FIG. 1 shows an exhaust component assembly 10 with a combustor 12. The combustor 12 comprises any type of combustor where air-assisted fuel injection is replaced by airless injection. Examples of such combustors would include vehicle exhaust after treatment components, auxiliary vehicle passenger compartment heaters, turbine combustors, etc.

[0015]The exhaust component assembly 10 includes a housing 14 defining an internal cavity 16 and an internal wall structure 18 that defines a combustion chamber 20. The housing 14 includes an exhaust gas inlet 22 and an exhaust gas outlet 24. Exhaust gases generated from an engine E flows through any upstream exhaust components 26 to the exhaust gas inlet 22. Exhaust gases flow through the exhaust component assembly 10 to the exhaust gas outlet 24 and then on to downstream exhaust system components 28.

[0016]At least one fuel nozzle 30 is supported by the housing 14 to inject / spray fuel from a fuel supply 32 into the combustion chamber 20. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com