Blank firing barrels for semiautomatic pistols and method of repetitive blank fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

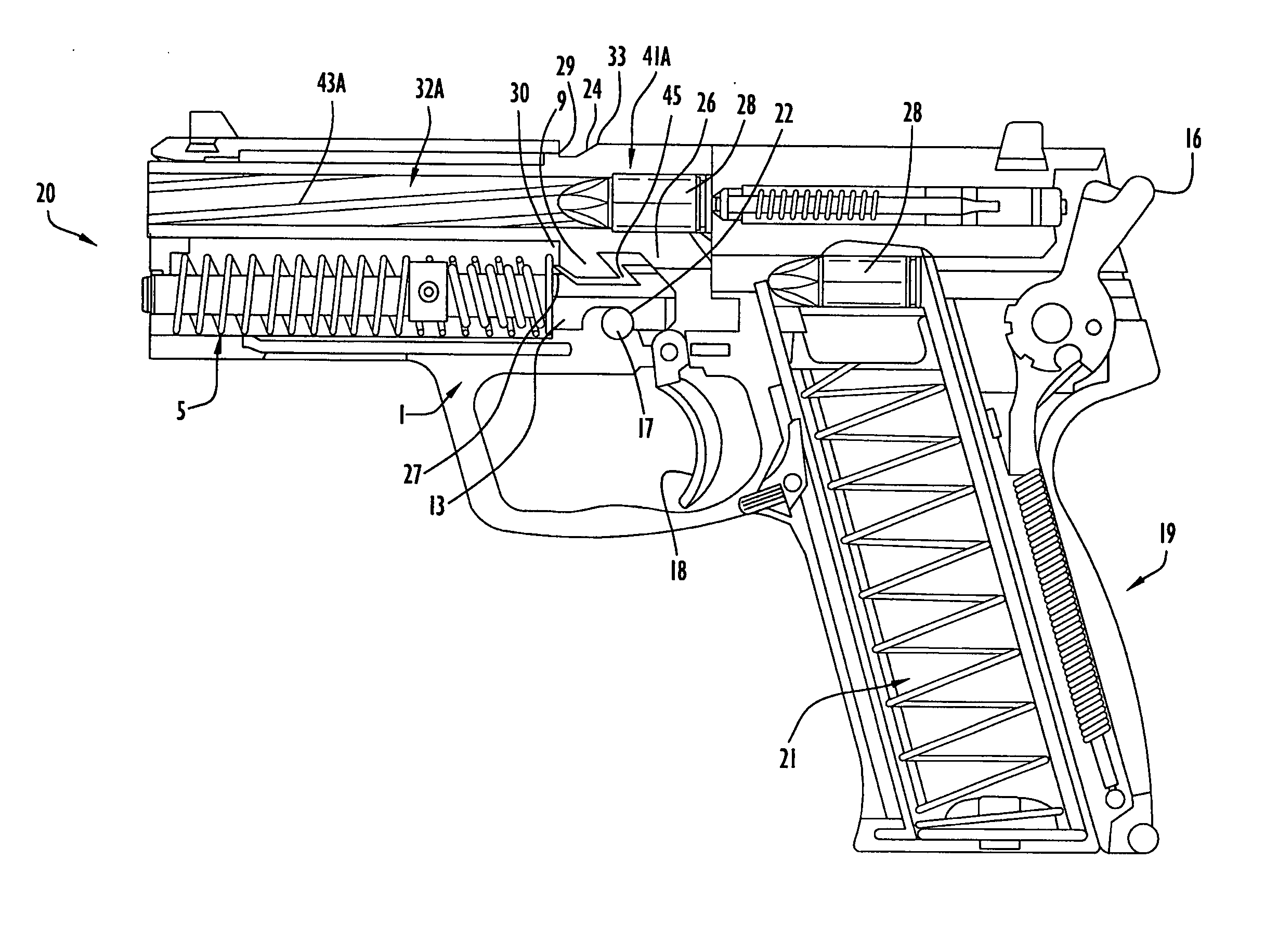

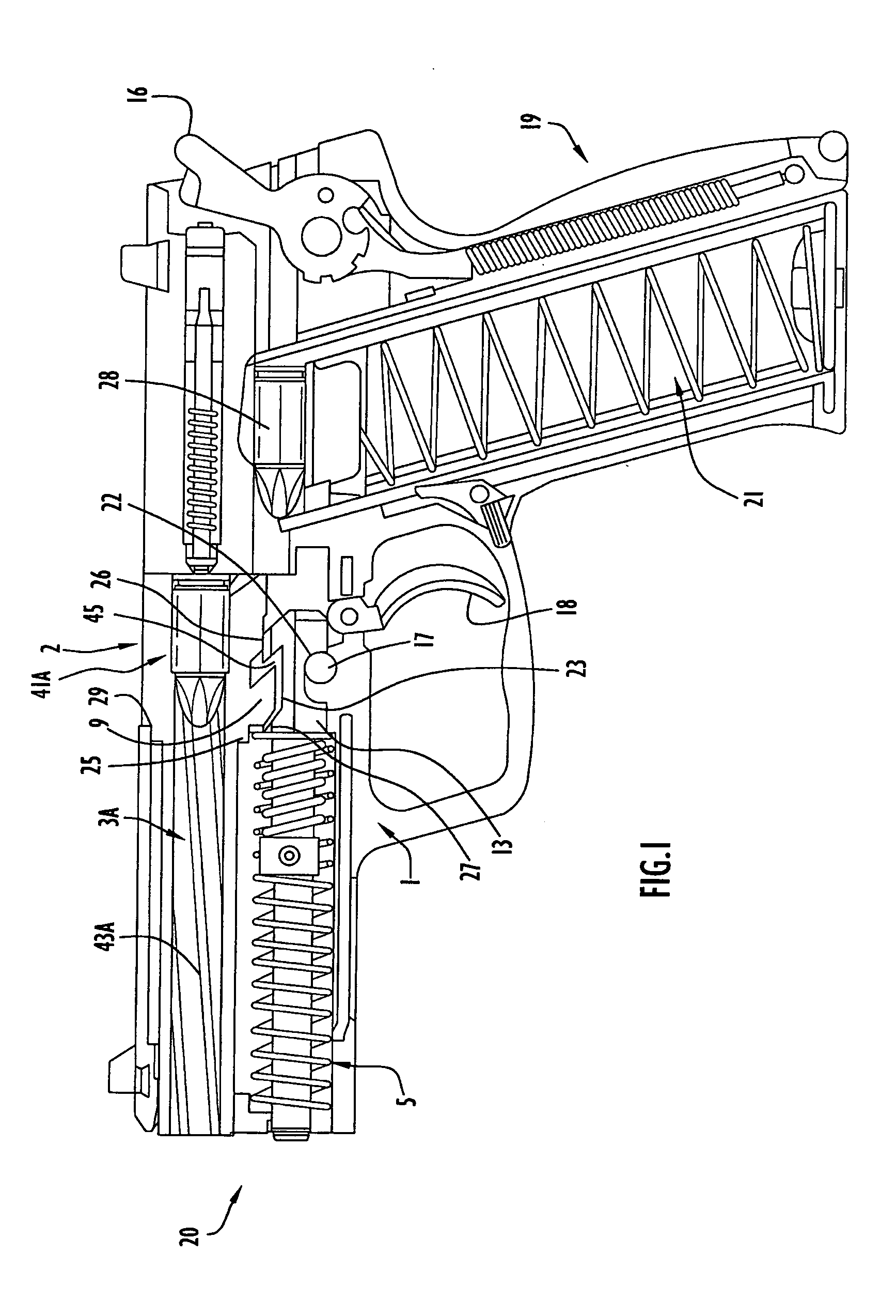

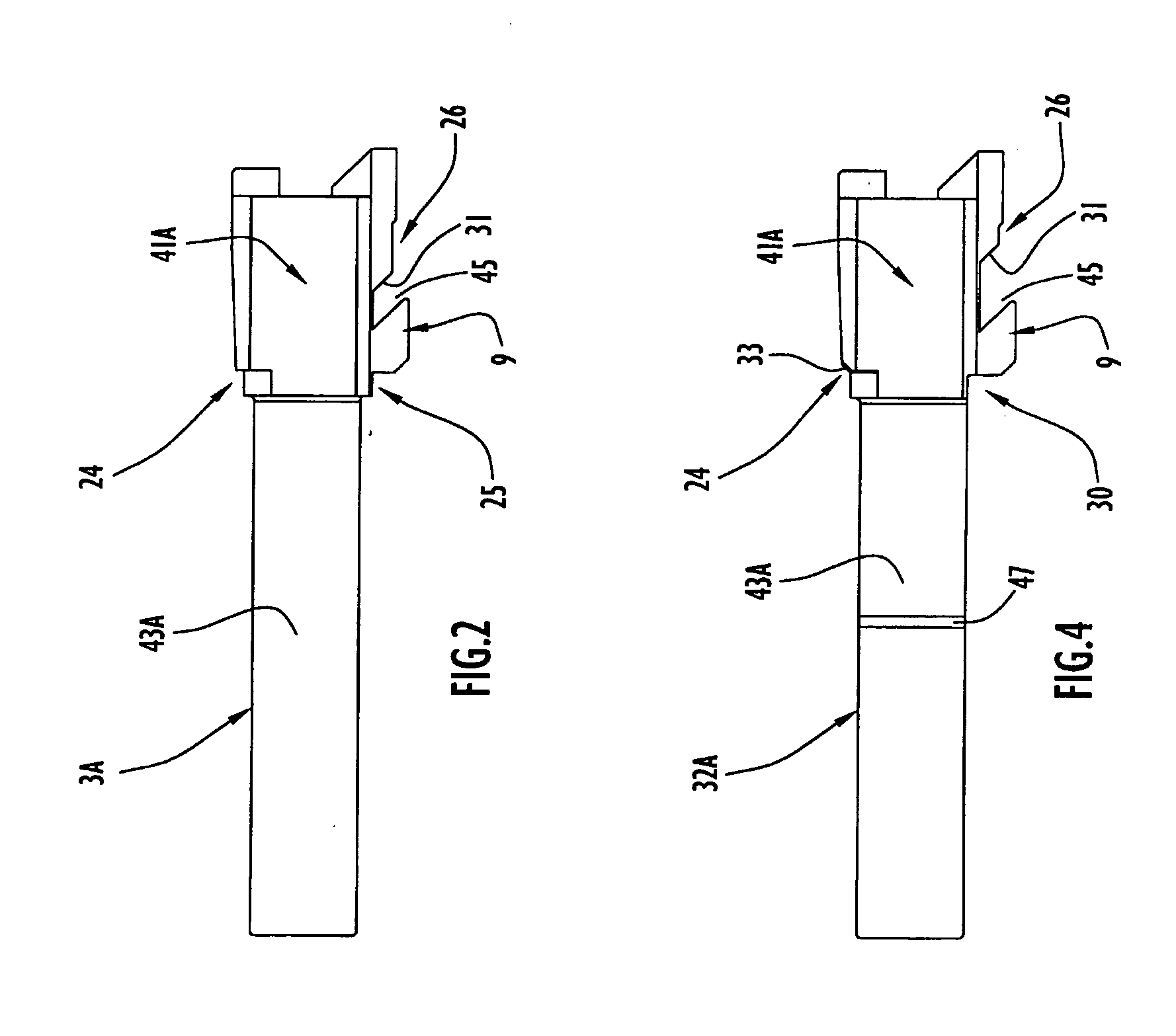

[0027]An example Heckler and Koch type pistol 20 for use with present invention embodiments is illustrated in FIGS. 1-2. Specifically, firearm or pistol 20 includes a frame 1, a slide 2 mounted on frame 1, a barrel unit 3A, and a recoil spring mechanism 5. Frame 1 includes a trigger mechanism 18 with a hammer 16, and a handle or grip portion 19 housing a magazine 21 for storage of one or more cartridges 28. Slide 2 is mounted on frame 1 and is adapted for reciprocal longitudinal movement on the frame in response to firing of pistol 20. Barrel unit 3A includes a chamber portion 41A and a barrel portion 43A. The chamber portion underside or bottom surface includes forward understations or projections 9, 25 and a rear understation or projection 26. Projections 9 and 25 adjoin each other with projection 25 basically forming a shoulder (e.g., or non-planar geometry) with the bottom surface of barrel portion 43A, while rear projection 26 is separated from front projection 9 by a suitably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com