Soap tape dispenser

a dispenser and soap technology, applied in the field of mold packaging, can solve the problems of limiting the manner in which the film may be dispensed, consuming a lot of resources, so as to prevent reduce the effect of premature activation and dissolution, and enhance the dispensing of appropriate amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In the following detailed description numerous specific details are set forth in order to provide a thorough understanding of the invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. For example, the invention is not limited in scope to the particular type of industry application depicted in the figures. In other instances, well-known methods, procedures, and components have not been described in detail so as not to obscure the present invention.

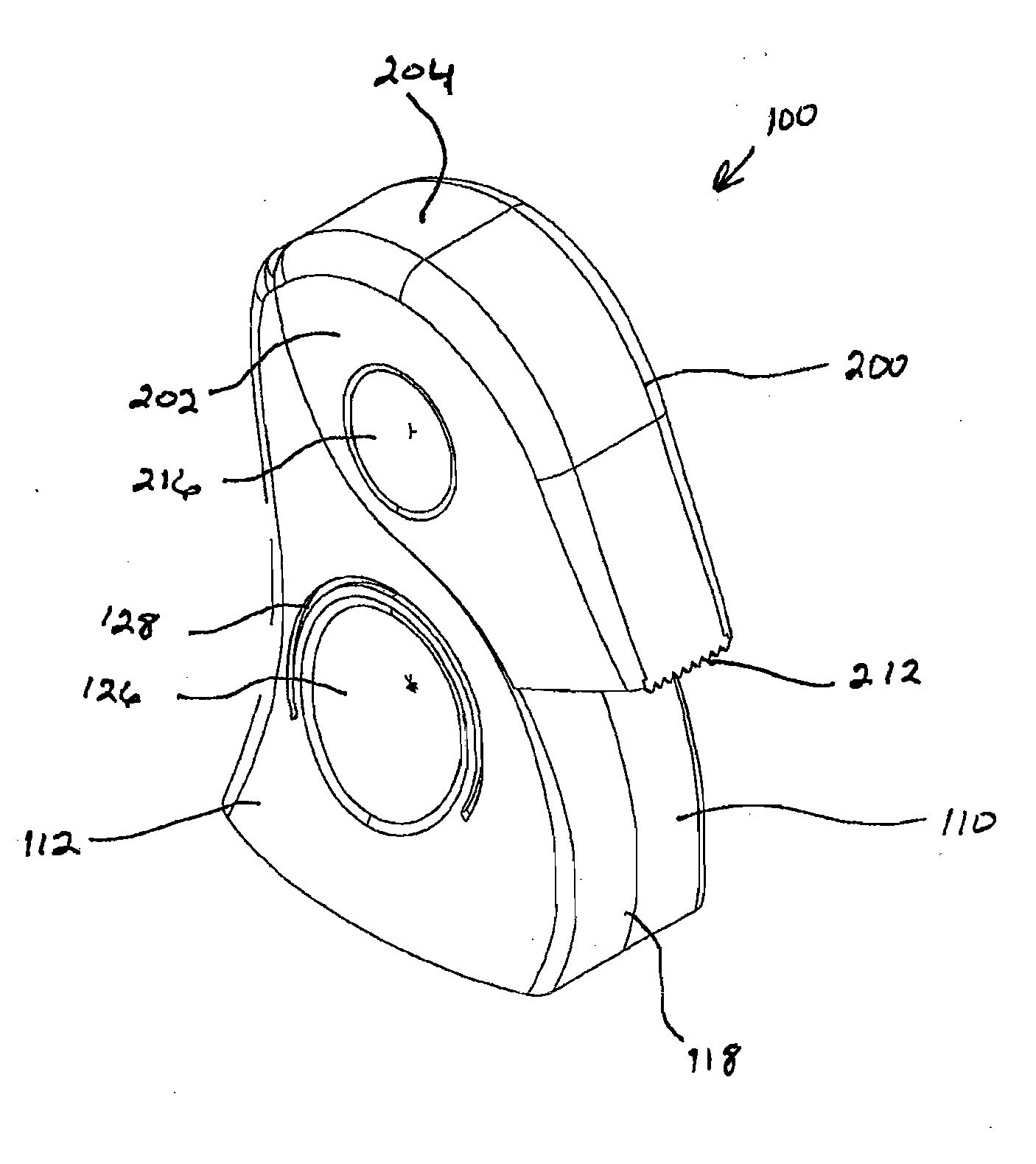

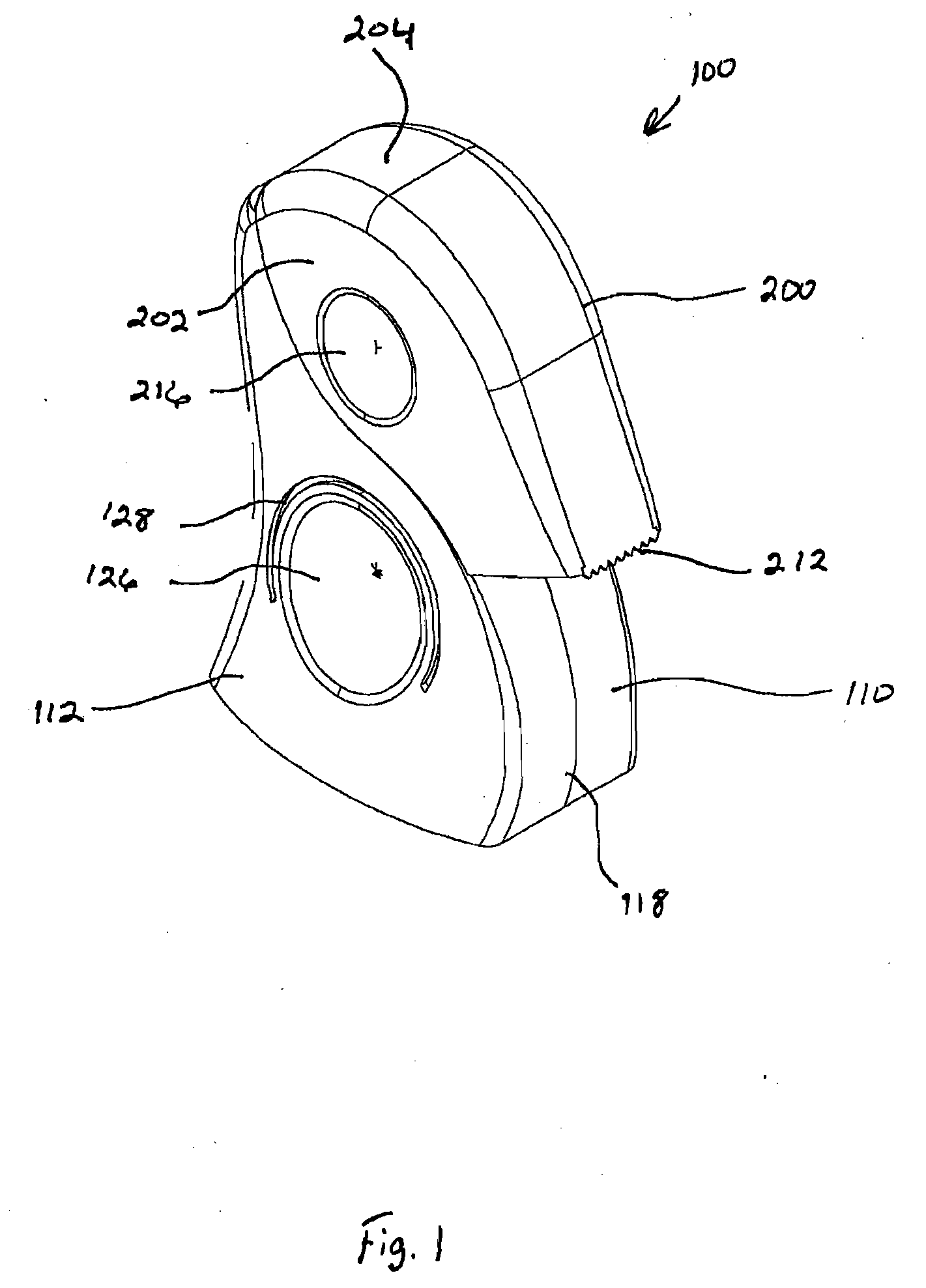

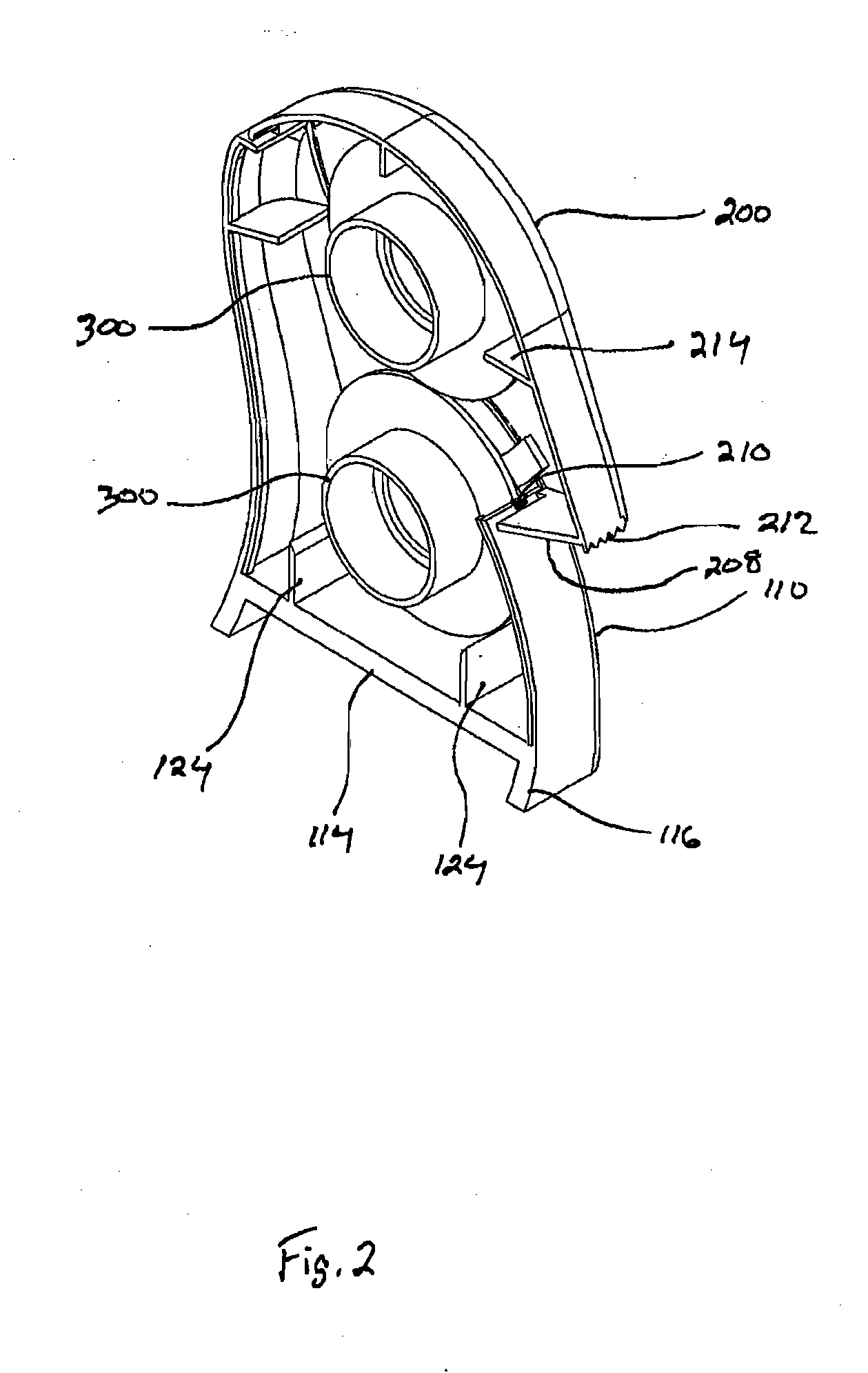

[0027]FIGS. 1-13 illustrate an embodiment of a soap tap dispenser system 100 according to one embodiment of the present invention. The dispenser system 100 includes a dispenser body 110 and top cover 200 that enclose two tape rolls 300. Each of these pieces and their constituent components can be manufactured using any suitable production method and raw materials. However, in the preferred embodiment, the closure is a molded from a material suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com