Low concentrations of gas bubbles to hinder proppant settling

a proppant settling and low concentration technology, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of insufficient foam production and insufficient proppant settling rate, and achieve the effect of reducing proppant settling ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

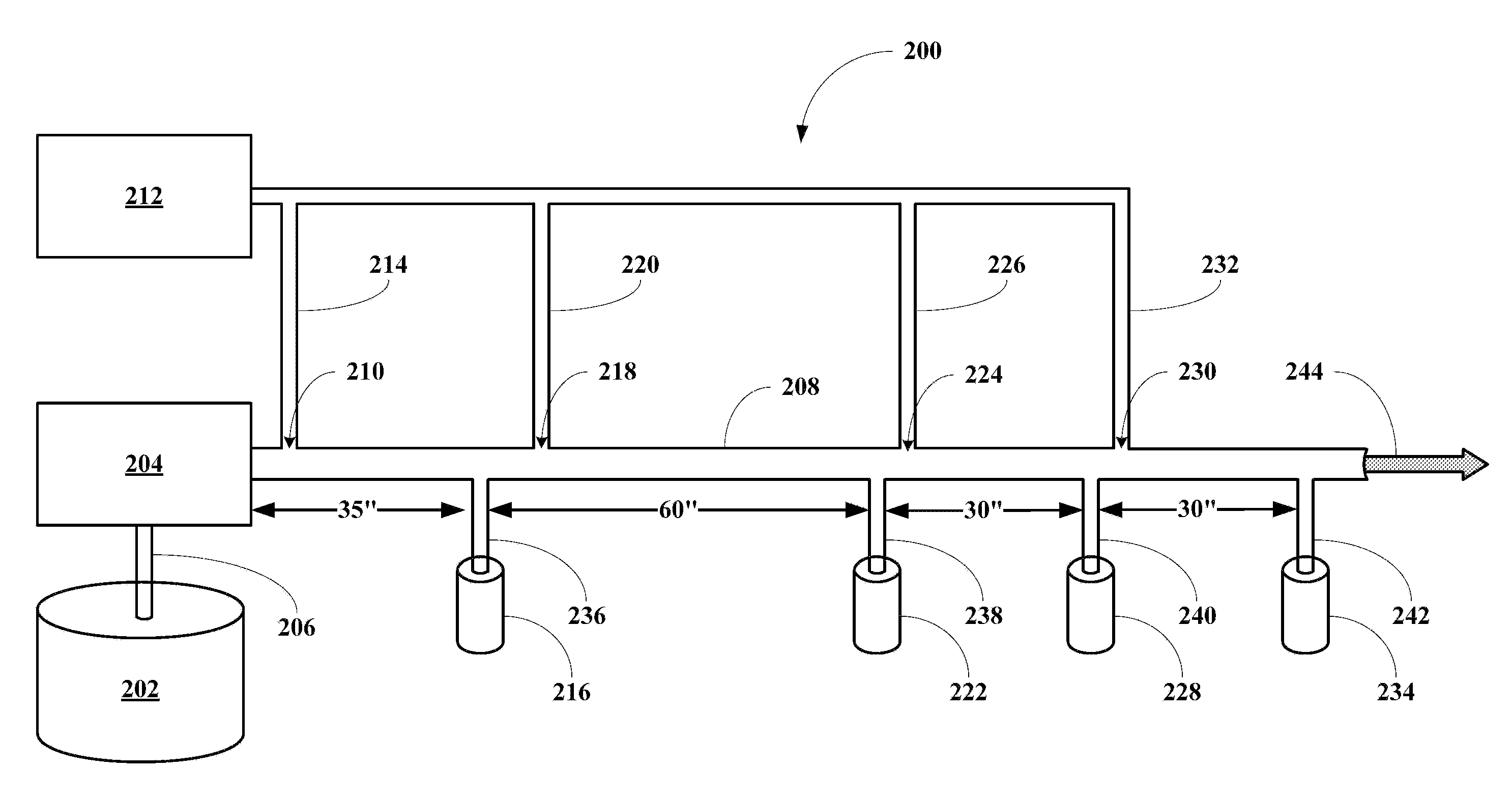

[0062]In this example, proppant settling rates were measured using a slick water fracturing fluid, where the fluid includes a proppant in the apparatus of FIG. 1. The proppant used was 20 / 40 sand in an amount of 0.5 lb / gal of the slick water fracturing fluid.

[0063]The slick water fracturing fluid including the sand was pumped by the pump 104 from its slurry tank 102 into the flow line 108 at flow rates between 1.42 gal / min and 1.31 gal / min. Air was used as the gas in this example and was supplied from a cylinder or unit 112 into the line 108 via the line 114 at flow rates between 0 gal / min and 0.120 gal / min, corresponding to a gas phase percentage between 0% and 9.16% gas. The settling rate at the four stations 116, 118, 120 and 122 were measured and are tabulated in Table 1.

TABLE 1Slick Water Fracturing Fluid Proppant Suspension TestFlow RateFlow RateSlick WaterTime to FillTime to FillTime to FillTime to FillAirFrac Fluid% GasStation 1Station 2Station 3Station 4Test #(gal / min)(gal / ...

example 2

[0070]In this example, proppant settling rates were measured using a guar gum fracturing fluid, where the fluid includes a proppant in the apparatus of FIG. 1. The proppant used was 20 / 40 sand in an amount of 0.5 lb / gal of the guar gum fracturing fluid.

[0071]The guar gum fracturing fluid including the sand was pumped by the pump 104 from its slurry tank 102 into the flow line 108 at flow rates between 1.32 gal / min and 1.21 gal / min. Air was used as the gas in this example and was supplied from a cylinder or unit 112 into the line 108 via the line 114 at flow rates between 0 gal / min and 0.123 gal / min, corresponding to a gas phase percentage between 0% and 10.17% gas. The settling rate at the four stations 116, 118, 120 and 122 were measured and are tabulated in Table 2.

TABLE 2Guar Gum Fracturing Fluid Proppant Suspension TestFlow RateFlow RateGuar GumTime to FillTime to FillTime to FillTime to FillAirFrac Fluid% GasStation 1Station 2Station 3Station 4Test #(gal / min)(gal / min)Phase(sec)...

example 3

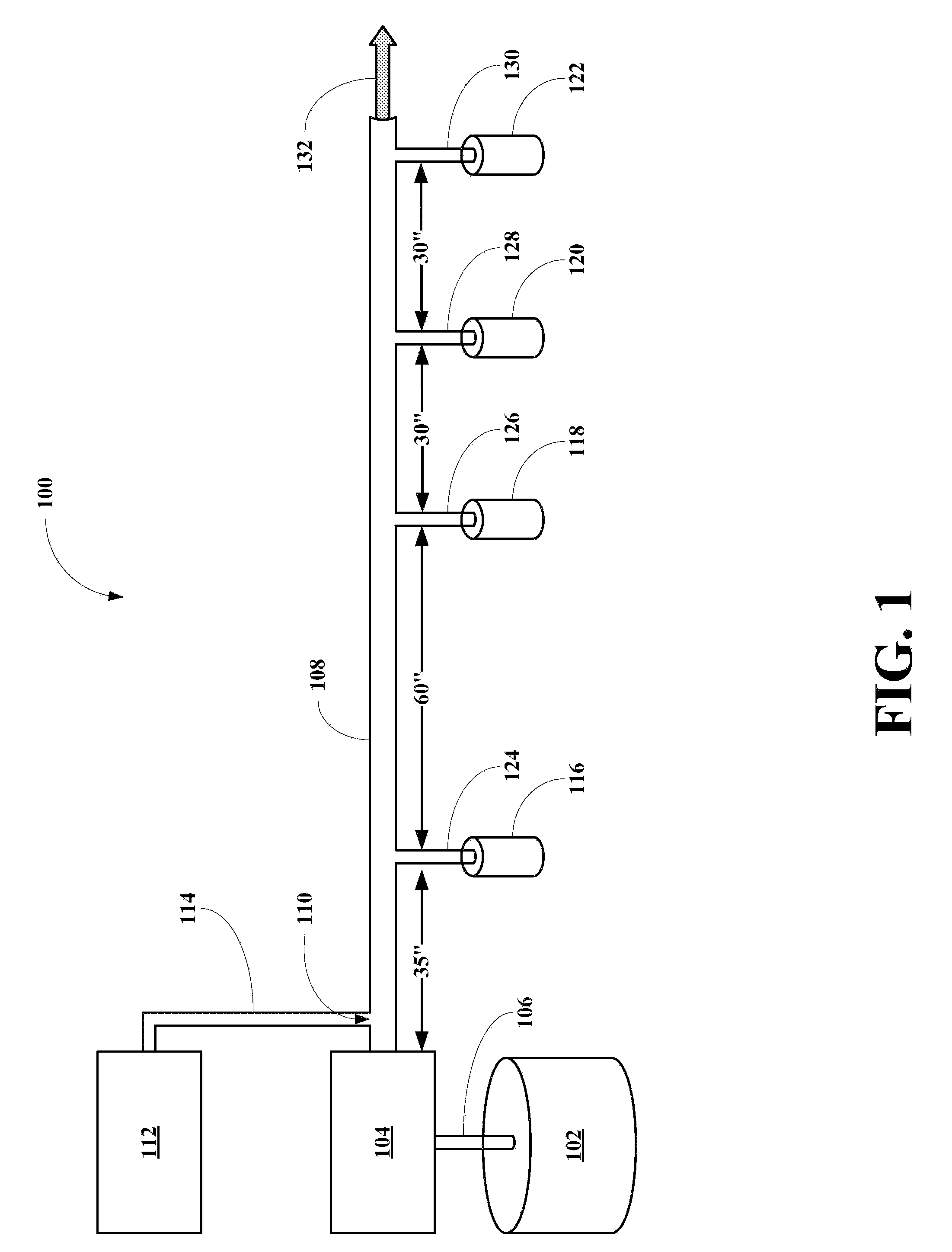

[0078]In this is a prophetic example, proppant settling rates are measured using a slick water fracturing fluid, where the fluid includes a proppant in the apparatus of FIG. 2. The proppant use is 20 / 40 sand in an amount of 0.5 lb / gal of the slick water fracturing fluid.

[0079]The slick water fracturing fluid including the sand is pumped by the pump 104 from its slurry tank 202 into the flow line 208 at flow rates between 1.42 gal / min and 1.31 gal / min. Air is used as the gas in this example and is supplied from a cylinder or unit 212 into the line 208 via the lines 214, 220, 226, and 232 at flow rates between 0 gal / min and 0.120 gal / min, corresponding to a gas phase percentage between 0% and 9.16% gas. The settling rate at the four stations 216, 222, 228 and 234 are measured and tabulated in Table 3.

TABLE 3Slick Water Fracturing Fluid Proppant Suspension TestFlow RateFlow RateSlick WaterTime to FillTime to FillTime to FillTime to FillAirFrac Fluid% GasStation 1Station 2Station 3Stati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume fraction | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com