Scroll fluid machine

a fluid machine and scrolling technology, applied in the direction of liquid fuel engines, positive displacement liquid engines, piston pumps, etc., can solve the problems of difficult to secure offset thrust loads acting on the right and left orbiting scrolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

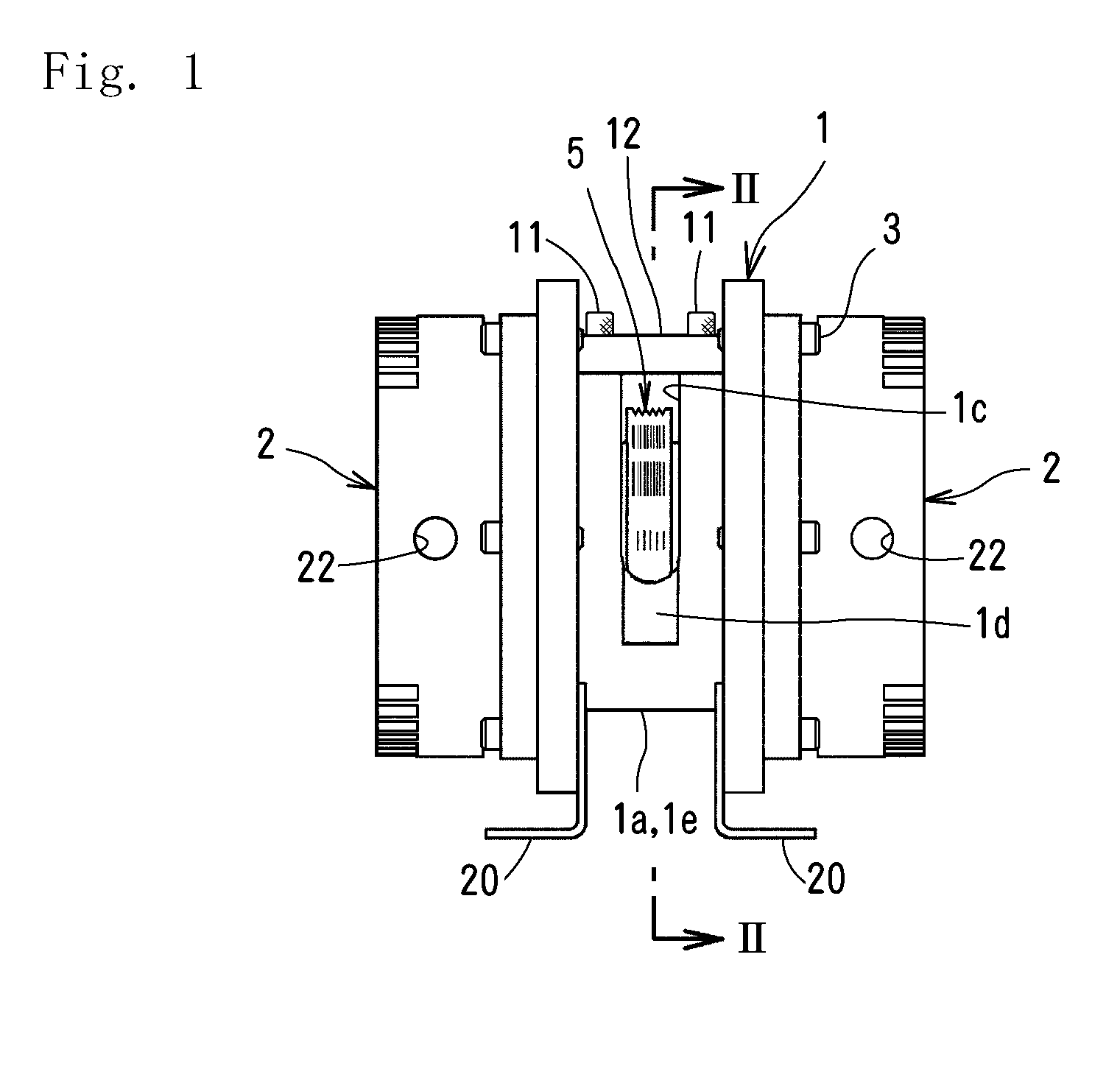

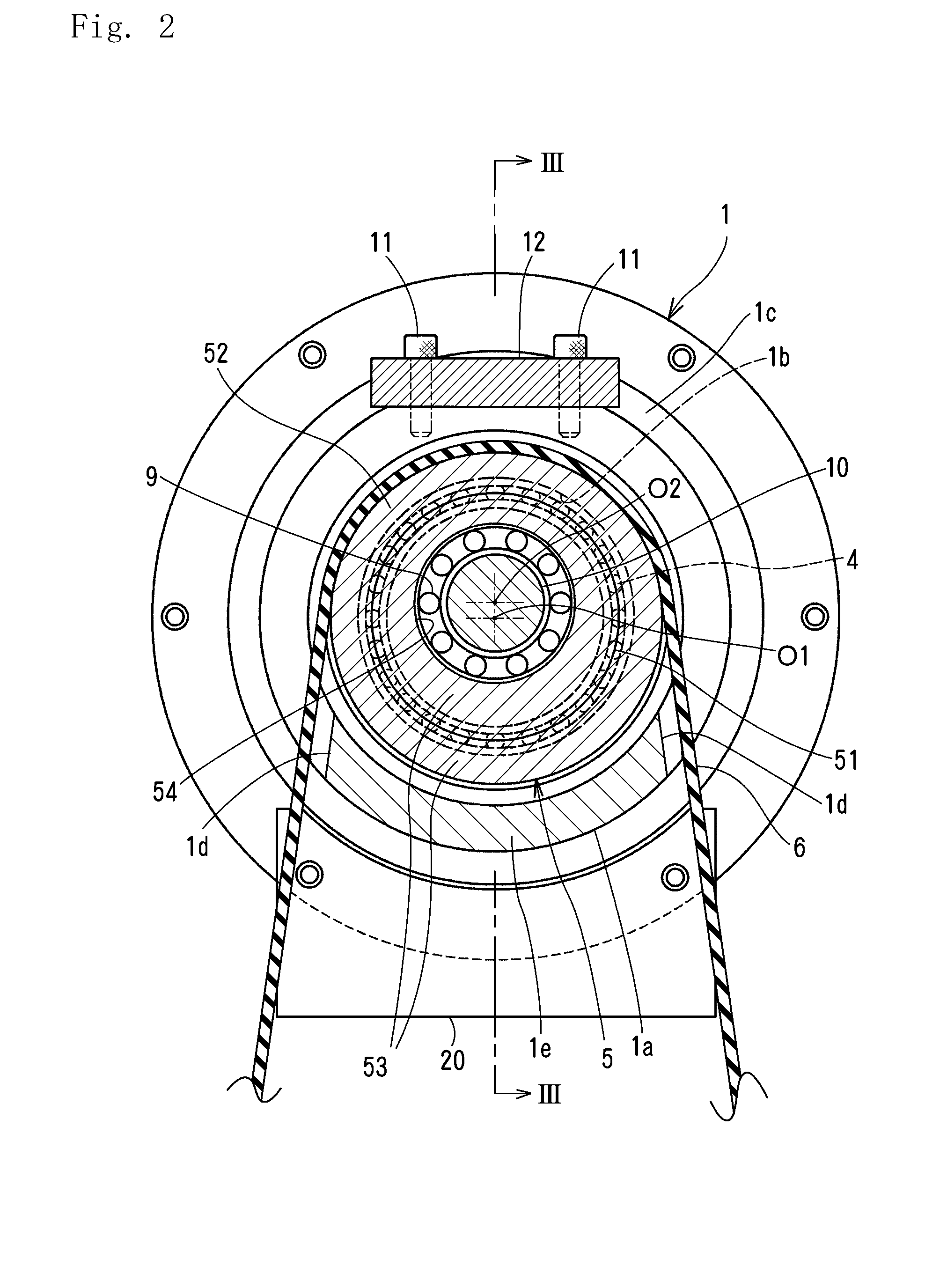

[0012]One embodiment of the present invention will be described with respect to the drawings.

[0013]In FIGS. 1 and 3, at each side of a cylindrical housing 1 of a scroll fluid machine, a fixed scroll 2 which includes a fixed wrap 21 is fixed with a plurality of screws. L-shaped feet 20, 20 which are fixed on a support (not shown) are fixed to the lower part of the housing 1.

[0014]On the inner side surface of the fixed scroll 2, a spiral orbiting scroll 3 which has a spiral orbiting wrap 31 engages with the fixed wrap 21 to form a compression chamber so as to rotate around the first axis O1.

[0015]The right-hand orbiting scroll 2 is disposed on the inside of the housing 1 with three known pin-crank-type self-rotation preventing devices 30 spaced on a circle by 120 degrees. Only one of the self-rotation preventing devices is shown in FIG. 3. In this embodiment, the right and left orbiting scrolls 3, 3 are fixed at the right and left ends of a thrust offsetting shaft 10. Thus, the pin-cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com