Vent Member and Vent Structure

a technology of vent structure and vent member, which is applied in the direction of ventilation system, electrical apparatus casing/cabinet/drawer, container preventing decay, etc., can solve the problems of not always the case, and achieve the effect of maintaining gas permeability, preventing water droplets, and maintaining gas permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

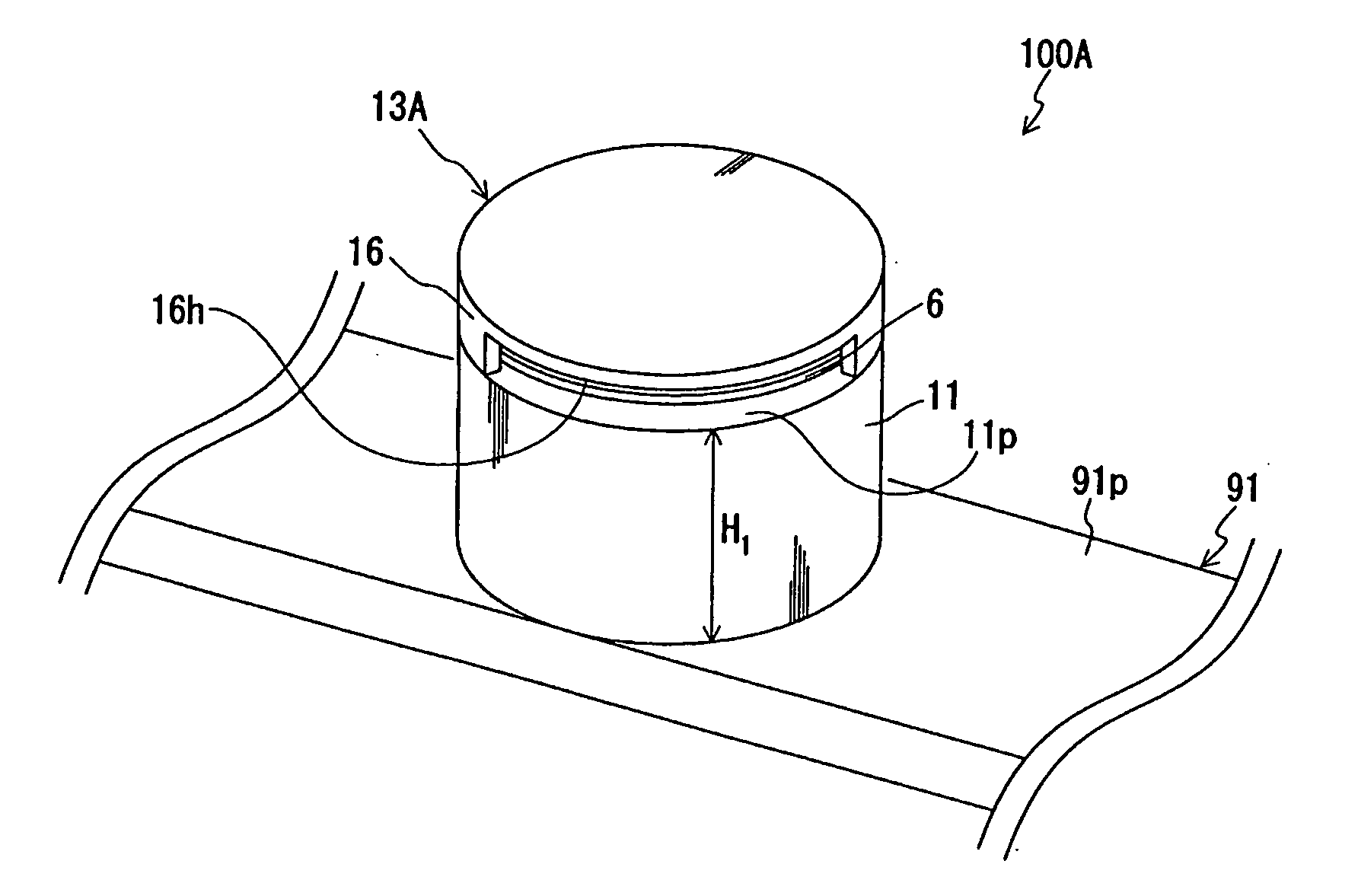

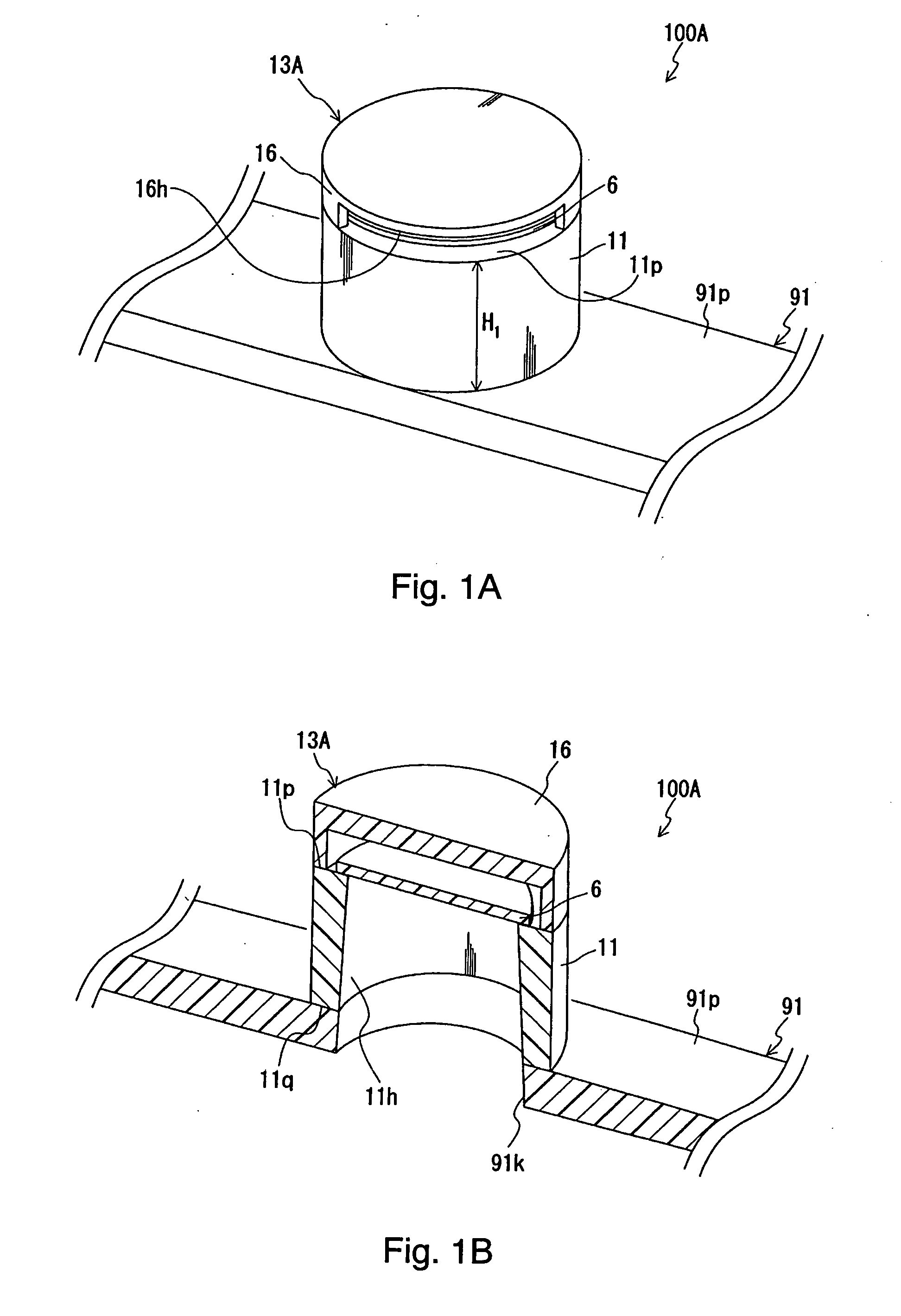

[0043]Hereinafter, embodiments of the present invention will be described with reference to the attached drawings. FIG. 1A is a perspective view of a vent member of a first embodiment according to the present invention, and FIG. 1B is a sectional perspective view thereof. FIG. 12 is a general view of a housing on which the vent member of FIG. 1A is attached. As shown in FIG. 12, the vent member 13A shown in FIGS. 1A and 1B constitutes a vent structure 100A for providing ventilation between the interior and the exterior of a housing 91 when attached to an opening portion 91k of the housing 91 of, for example, an automobile electrical component. The housing is not limited to a box-shaped housing as shown in FIG. 12. Any components or articles having an interior space that needs ventilation can be a housing to which the vent member of the present invention is to be attached.

[0044]As shown in FIGS. 1A and 1B, the vent member 13A is provided with a support body 11 having a through hole 1...

second embodiment

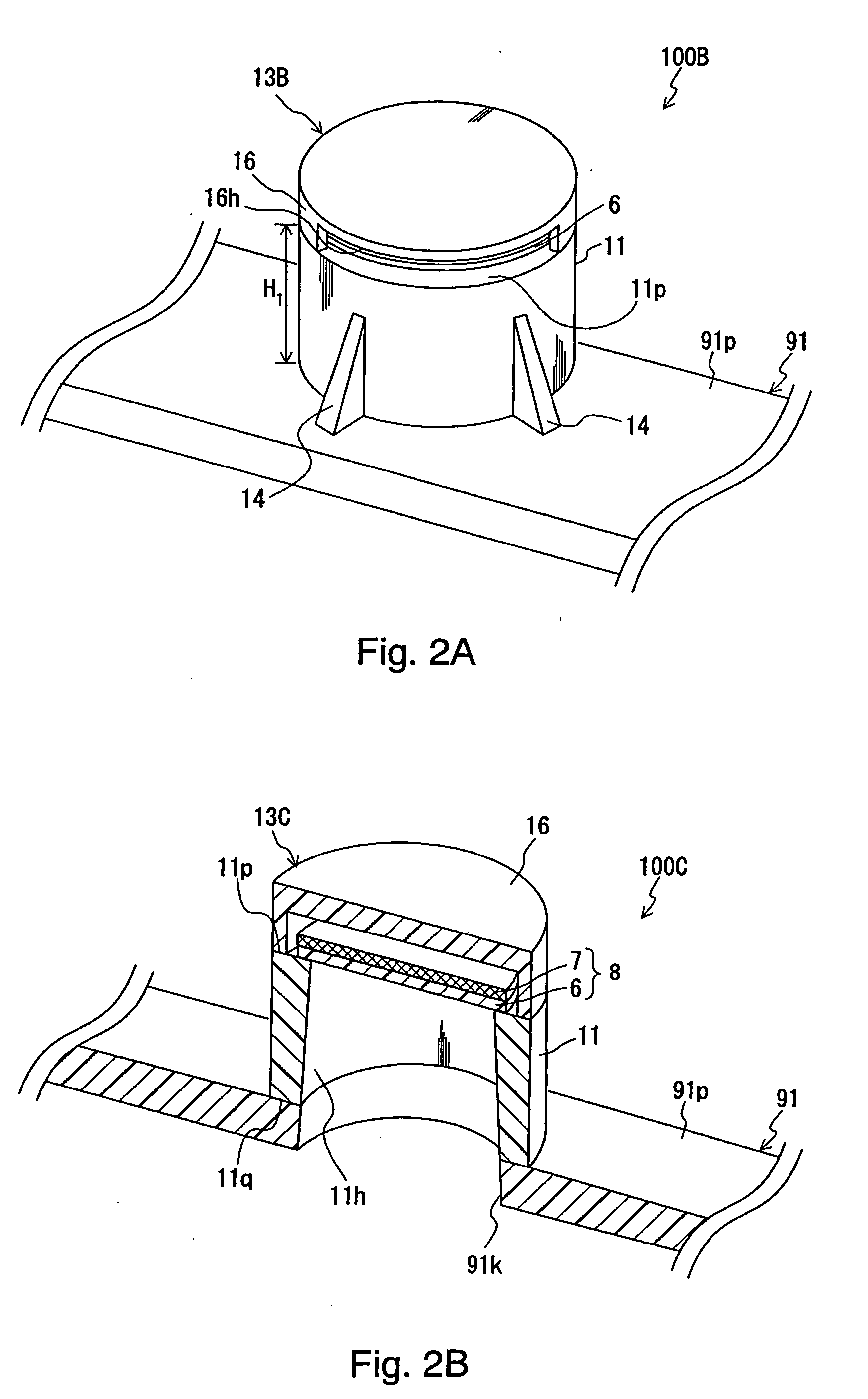

[0062]FIG. 3A is a perspective view of a vent member of a second embodiment, and FIG. 3B is a sectional perspective view thereof. A vent structure 102 for performing ventilation between the interior and the exterior of the housing 91 is constituted by attaching a vent member 23 shown in FIGS. 3A and 3B to the opening portion 91k of the housing 91.

[0063]The vent member 23 is provided with a support body 21 having a through hole 21h and 21i to serve as a gas passage between the interior and exterior of the housing 91 and the gas permeable membrane 6 fixed to the support body 21 so as to close the through hole 21h and 21i. A second opening end face 21q serves as a bonding surface that is directly bonded to the housing 91. The support body 21 includes a cover 26 covering the gas permeable membrane 6. A clearance between the gas permeable membrane 6 and the cover 26 communicates with an opening 26h that opens in a direction parallel to the in-plane of the gas permeable membrane 6. The ve...

third embodiment

[0068]A vent member 43A of a third embodiment shown in FIG. 4A is a modification of the vent member 23 of the second embodiment. A vent structure 106A is constituted by attaching the vent member 43A to the opening portion 91k of the housing 91. This embodiment is common with the embodiments above in that a through hole 41h and 41i is divided into an upper portion and a lower portion by the gas permeable membrane 6, a support body 41 includes a cover 46, and a height H7 from the outer surface 91p of the housing 91 to a first opening end face 41p is set to 4 mm or more. A difference is that the gas permeable membrane 6 is integrated with the support body 41 by insert molding.

[0069]As shown in FIG. 4A, the gas permeable membrane 6 is fixed to the support body 41 in the through hole 41h and 41i by integrating a peripheral portion 6k with the resin of which the support body 41 is composed. In other words, the peripheral portion 6k of the gas permeable membrane 6 is embedded into the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com