Double Side Polishing Machine

a polishing machine and side polishing technology, which is applied in the direction of edge grinding machines, lapping machines, manufacturing tools, etc., can solve the problems of large variation of the upper lapping plate by the variability of the rod, and achieve the effect of preventing deflection of the upper polishing plate, reducing the variability of the upper lapping plate, and increasing the strength of the supporting pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

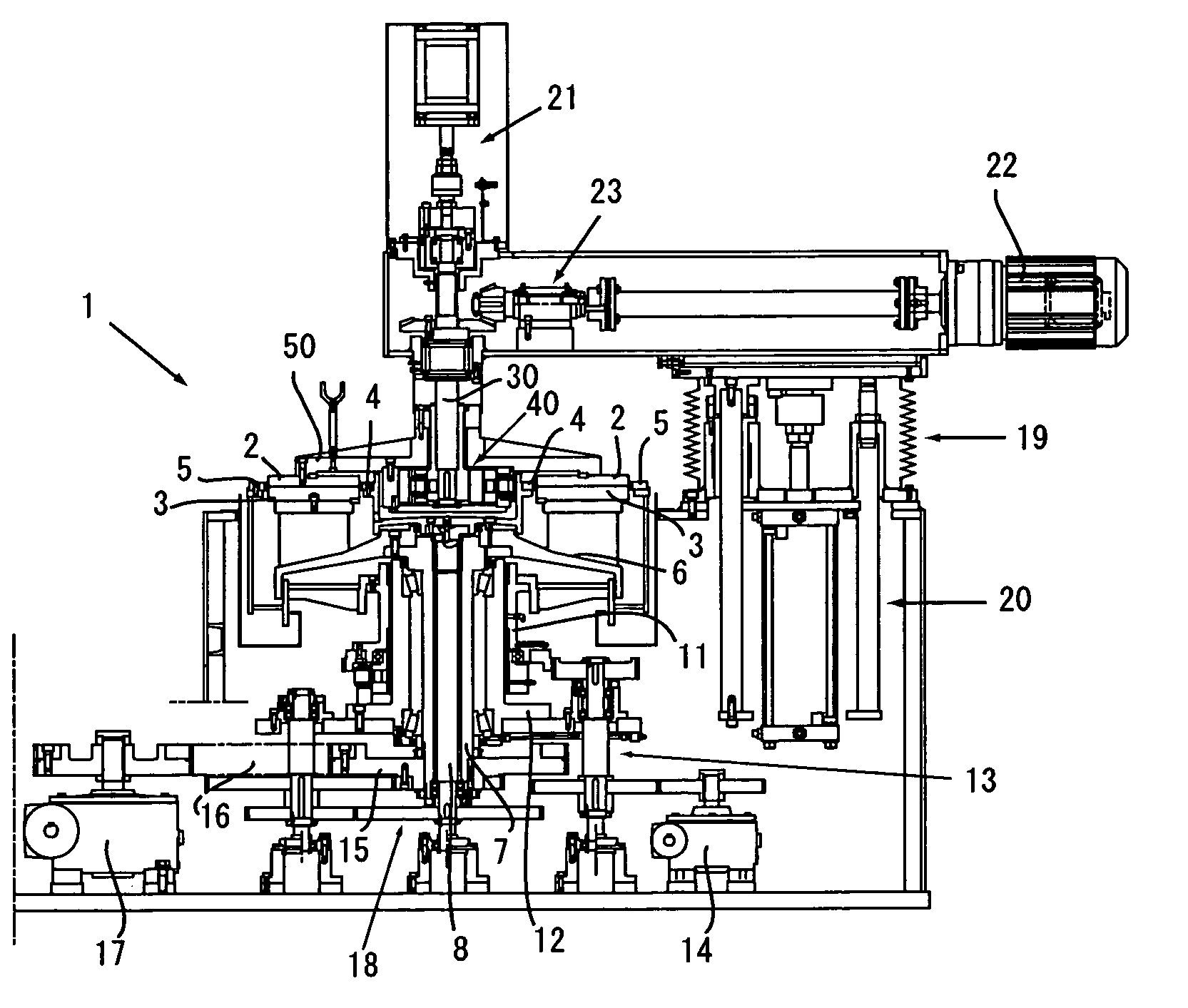

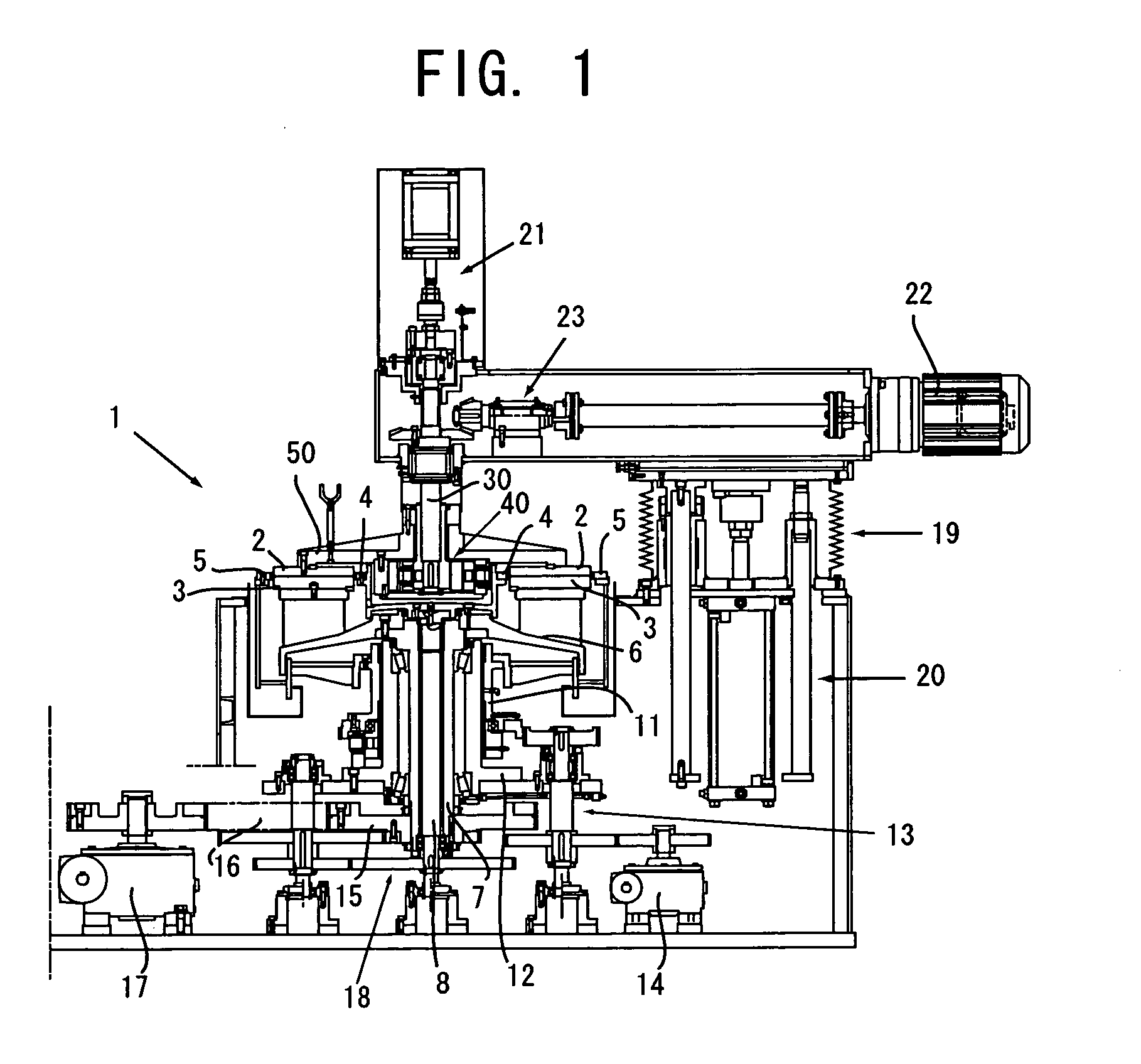

[0018]Hereinafter, an embodiment of the present invention is explained by referring drawings.

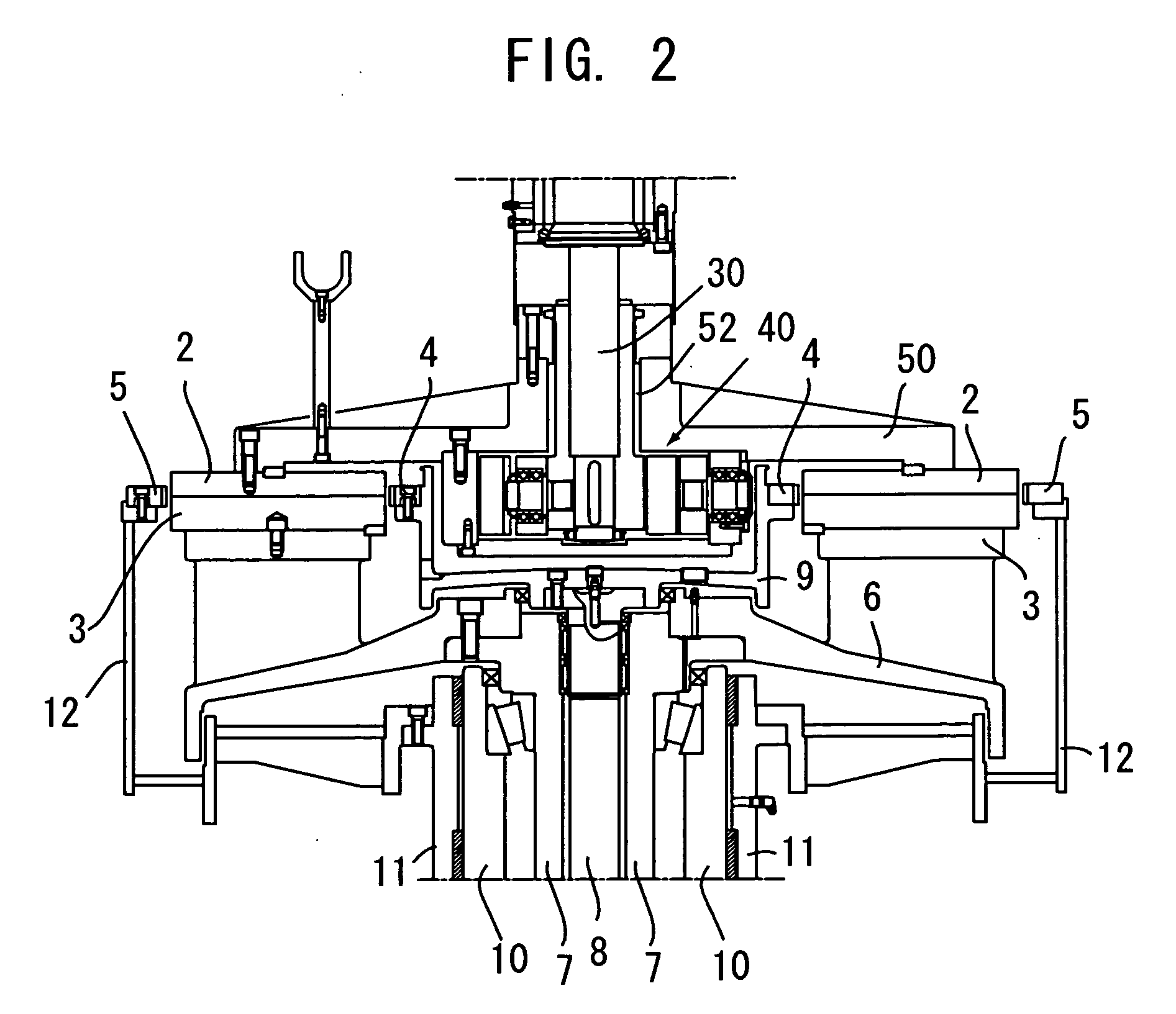

[0019]A double side polishing machine 1 according to an embodiment of the present invention comprises an upper polishing plate 2 and a lower polishing plate 3 between which a plurality of carriers not shown in figures installing plural works are put, and a sun gear 4 and an internal gear 5 with which the carriers are engaged in order to rotate and revolve.

[0020]The lower polishing plate 3 is secured on a supporting plate for lower polishing plate 6 to be held and rotated via a rotatable cylindrical shaft 7 on which the supporting plate 6 is secured. A rotation shaft 8 passing though the rotatable cylindrical shaft 7 is provided inside the rotatable cylindrical shaft 7, a closed-end and cylindrical sun gear portion 9 is secured at a front end of the rotation shaft 8, and then the sun gear 4 formed on an outer peripheral surface of the sun gear portion 9 is rotated with rotation of the rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com