Transient energy systems and methods for use of the same

a technology of energy systems and energy systems, applied in the field of transient energy systems, can solve the problems of poor reliability of batteries, large storage space, and high maintenance costs, and achieve the effects of reducing bearing load, increasing bearing life, and reducing bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

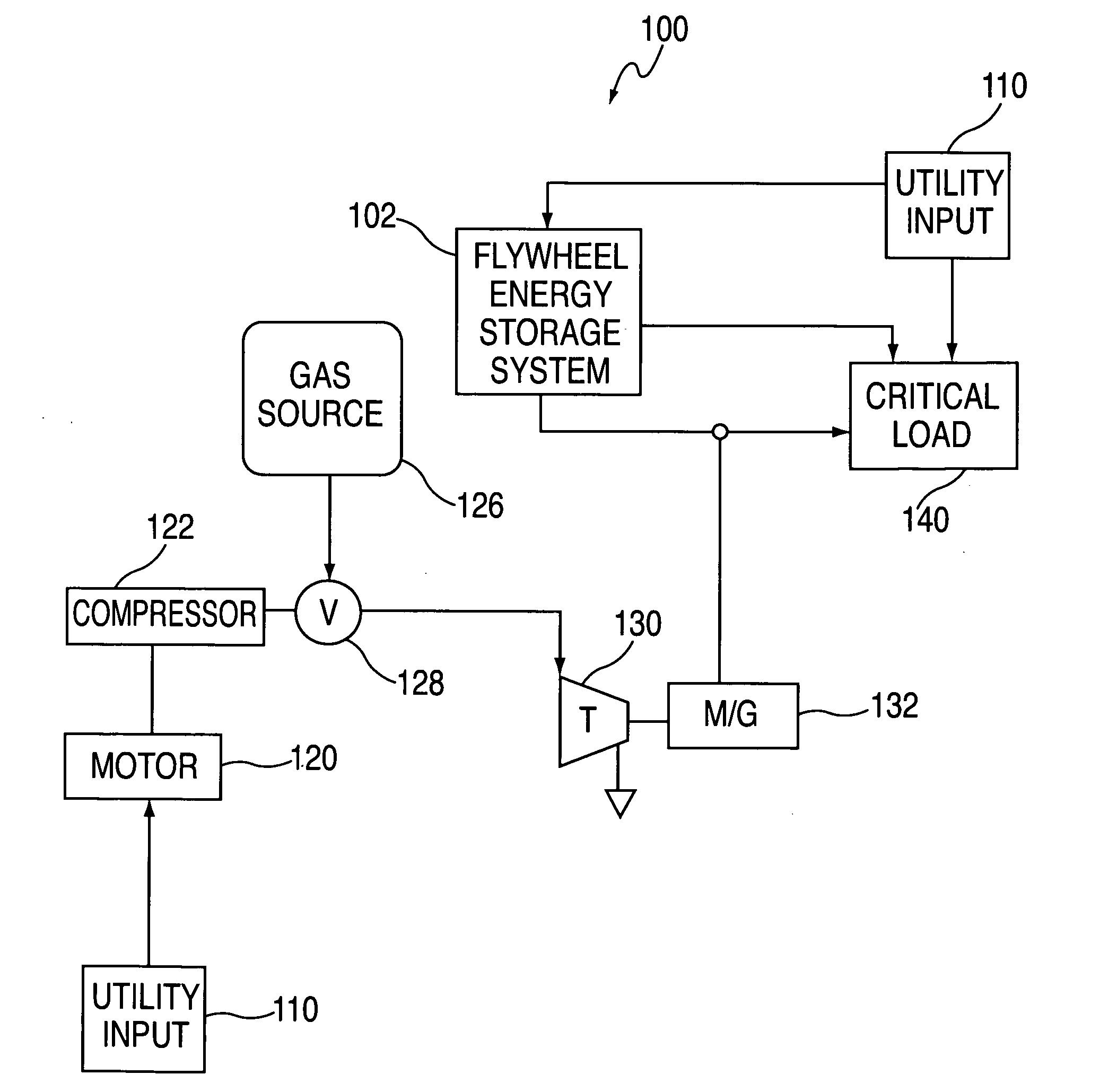

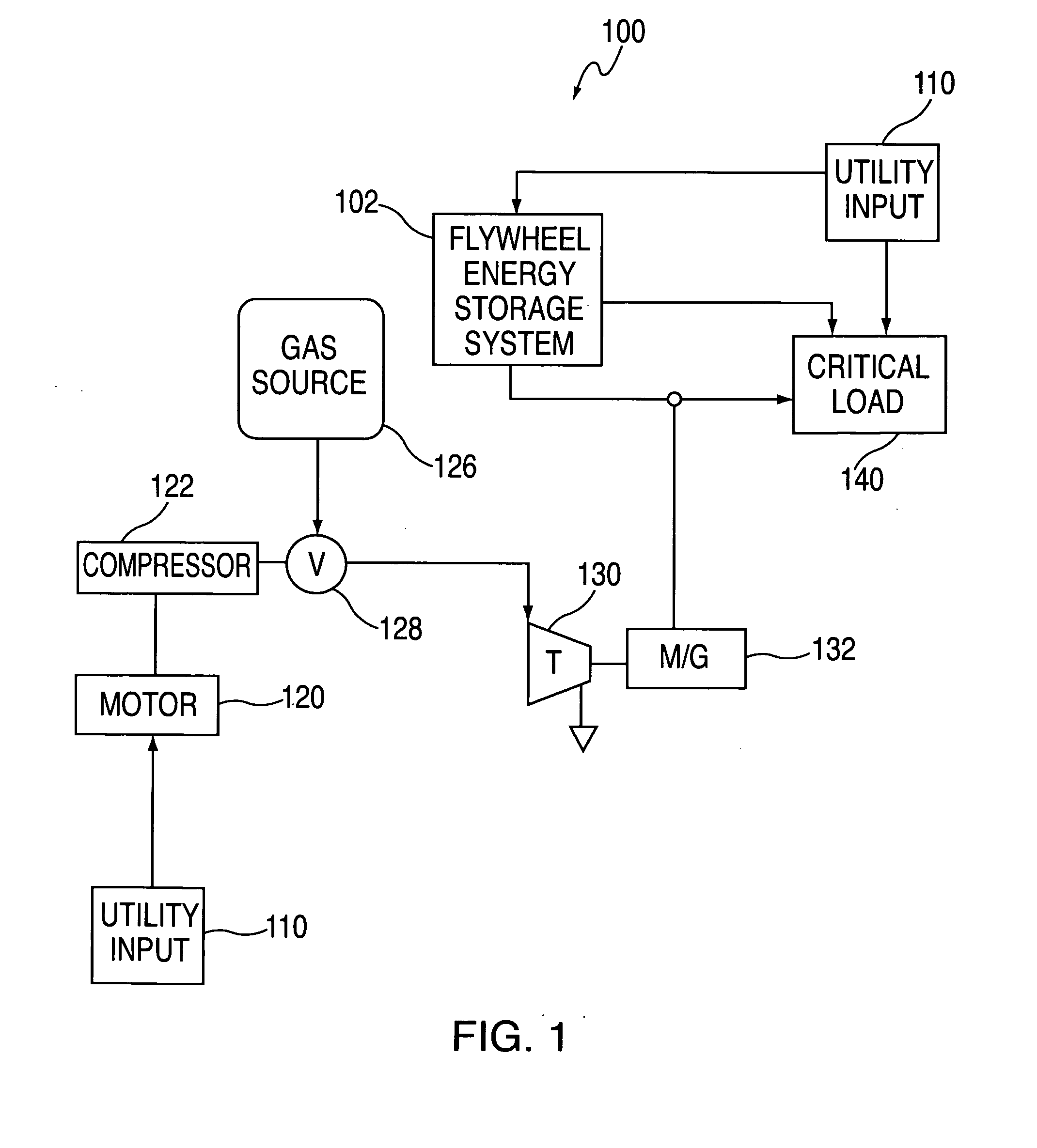

[0053]FIG. 1 shows a block diagram of a compressed air storage (CAS) backup energy system 100, including a flywheel energy storage system in accordance with the present invention, for providing backup power to a load. Backup energy system 100 includes utility input 110 which supplies power to critical load 140 during normal operating conditions. Persons skilled in the art will appreciate that utility input 110 may be any suitable type of primary power source. As illustrated in FIG. 1, backup energy system 100 includes a flywheel energy system 102 according to the principles of the present invention integrated with the components of a CAS system in order to provide backup power to critical load 140. Backup energy system 100 includes motor 120, compressor 122, gas source 126 (e.g., pressure tank), valve 128, turbine 130 and electrical machine 132.

[0054]During normal operating conditions, utility input 110 supplies critical load 140 with power. Utility power 110 also provides bridging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com