Backup safety flow control system for concentric drill string

a safety flow control and drill string technology, applied in the direction of drilling pipes, drilling casings, borehole/well accessories, etc., can solve the problems of reducing the ability to retrieve fluids later, affecting the safety of the operation, and affecting the operation of the valve assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

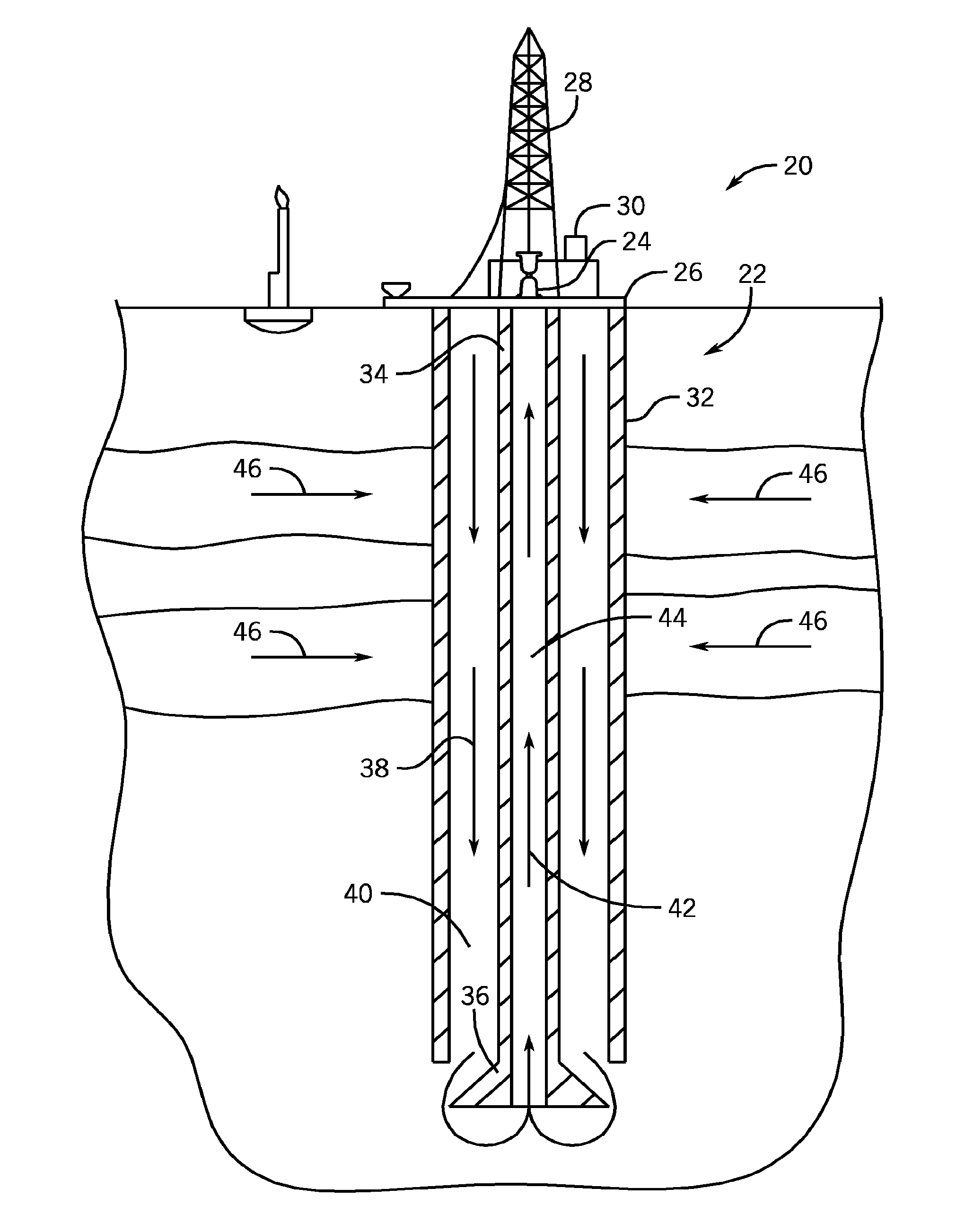

[0020]Referring now to FIG. 1, the present invention will be described as it might be applied in conjunction with an exemplary technique, in this case a drilling system for drilling wells, as represented generally by reference numeral 20. In the illustrated embodiment, the drilling system 20 comprises a concentric drill string 22. The drill string 22 is rotated by a rotary table 24 supported by a drilling platform 26. The drilling system 20 also comprises a derrick 28 to support the drill string 22 and its components during assembly and disassembly of the drill string 22. The illustrated system 20 also comprises a drilling fluid supply and recovery system 30. In this embodiment, the drilling fluid is a gas, such as air. However, other drilling fluids may be used.

[0021]In the illustrated embodiment, the drill string 22 is a concentric drill string having an outer housing 32 secured to an inner drill string 34. The drill string 22 also comprises a drill bit 36. As the drill string 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com