Fuel bottle for a fuel cartridge using the same.

a technology of fuel bottles and fuel cartridges, applied in the direction of transportation and packaging, other domestic articles, electrochemical generators, etc., can solve the problems of insufficient shape, capacity and formability of the inside container, and achieve the effect of improving the strength of the bottl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

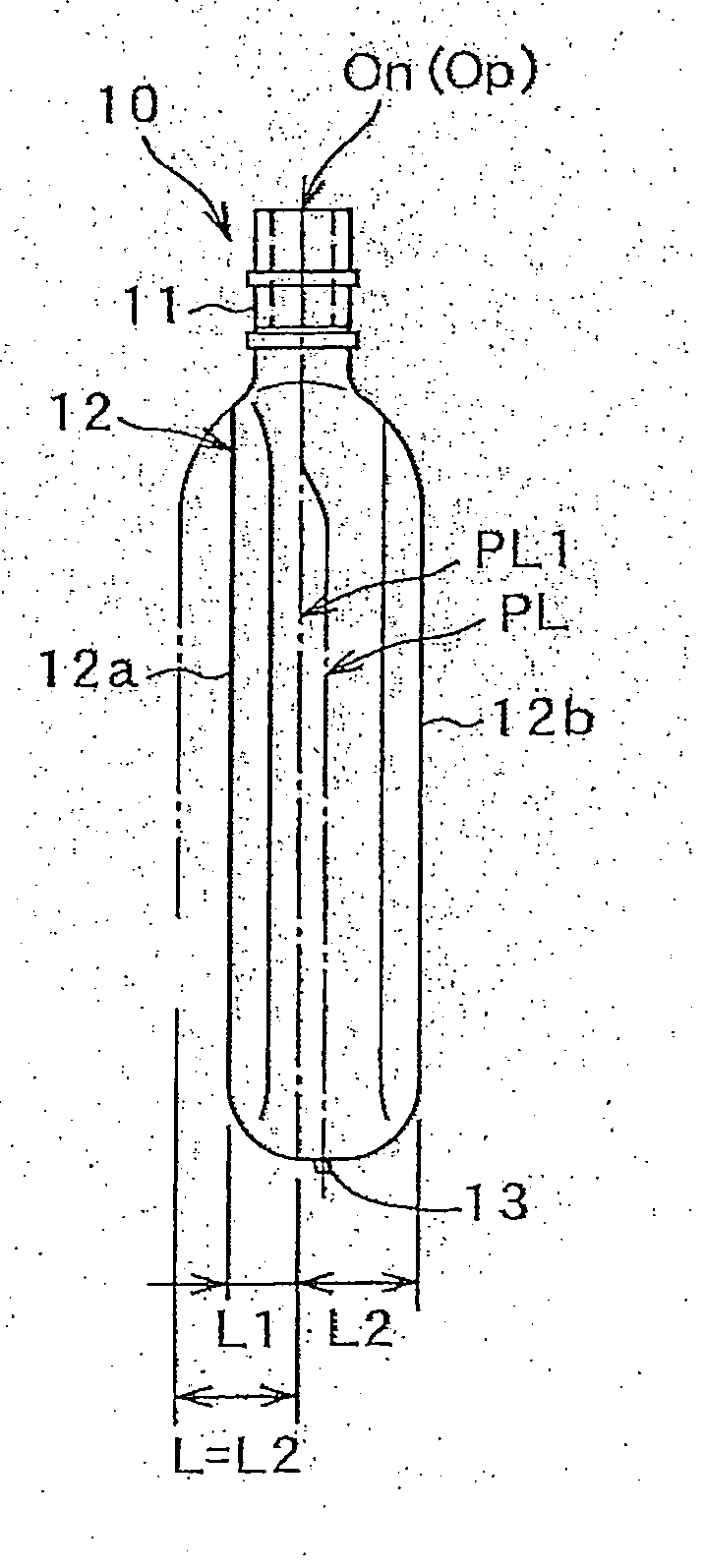

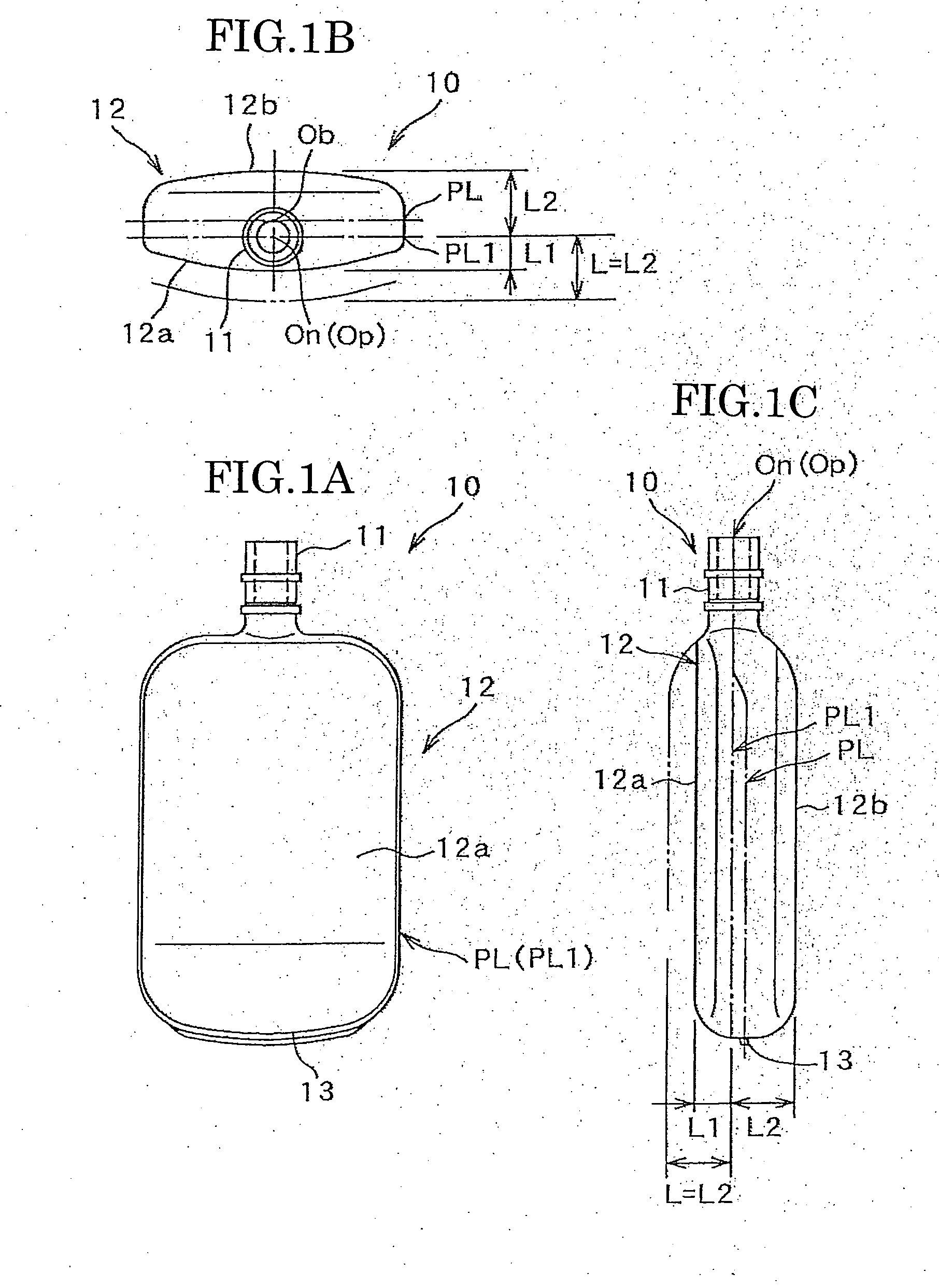

[0038]FIG. 1 shows a front view, a plan view and a side view of an embodiment of a fuel bottle for a fuel cell of the present invention.

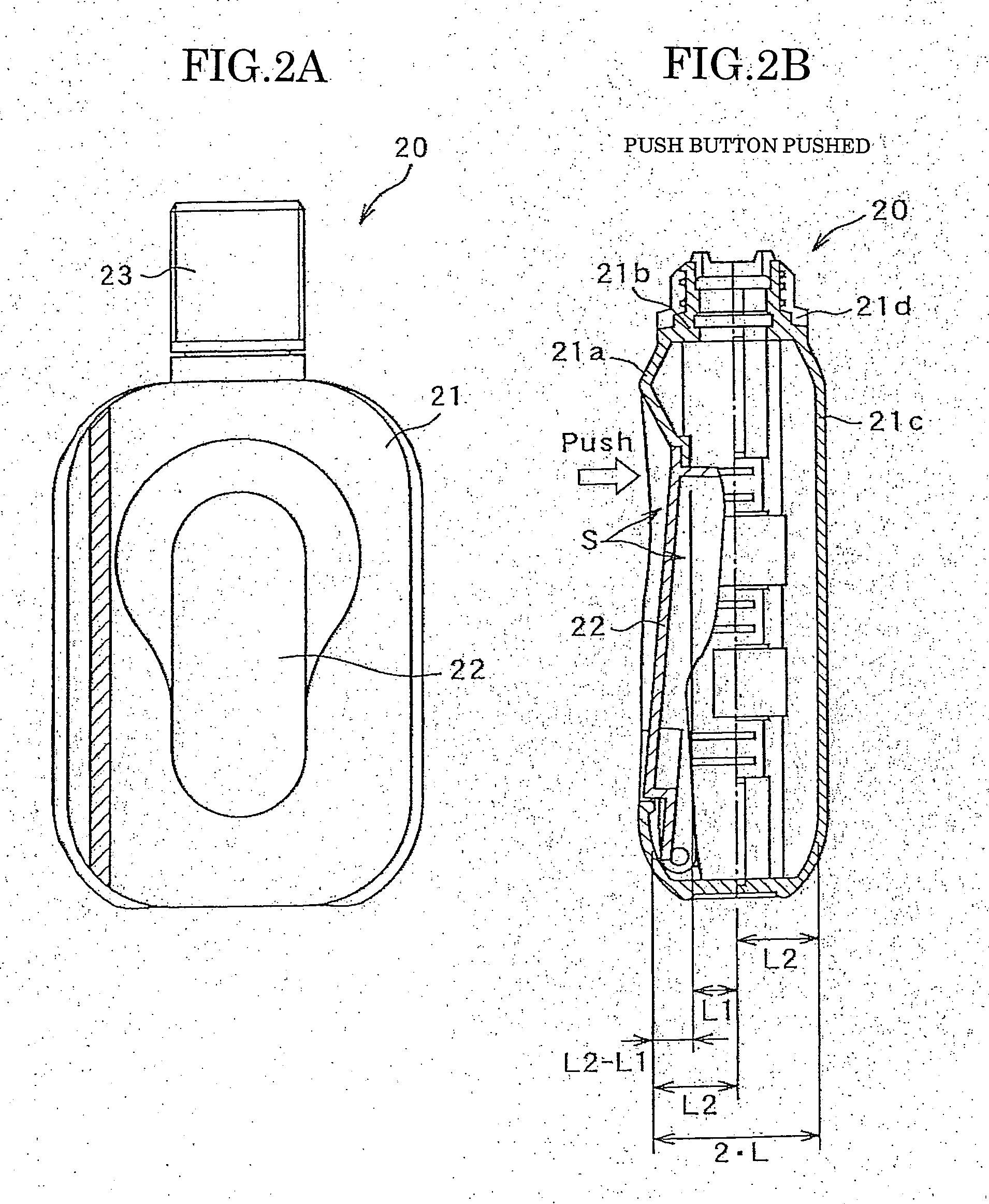

[0039]FIG. 2 shows a front view and a sectional view of an embodiment of a fuel cartridge of the invention using the fuel bottle for a fuel cell. FIG. 3 shows a sectional view of a blow mold used for molding the fuel bottle for a fuel cell of the invention and FIG. 4 shows a front view, a plan view and a side view of another embodiment of a fuel bottle for a fuel cell of the invention.

[0040]A fuel bottle 10 for a fuel cell is a fuel bottle for containing methanol for a passive type fuel cell according to which fuel is directly supplied to a fuel tank of a fuel cell main body of a direct methanol fuel cell (DMFC) using methanol as its fuel.

[0041]This fuel bottle 10 is formed, as shown in FIG. 1, is made of plastic having contractibil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com