Paper corner protector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

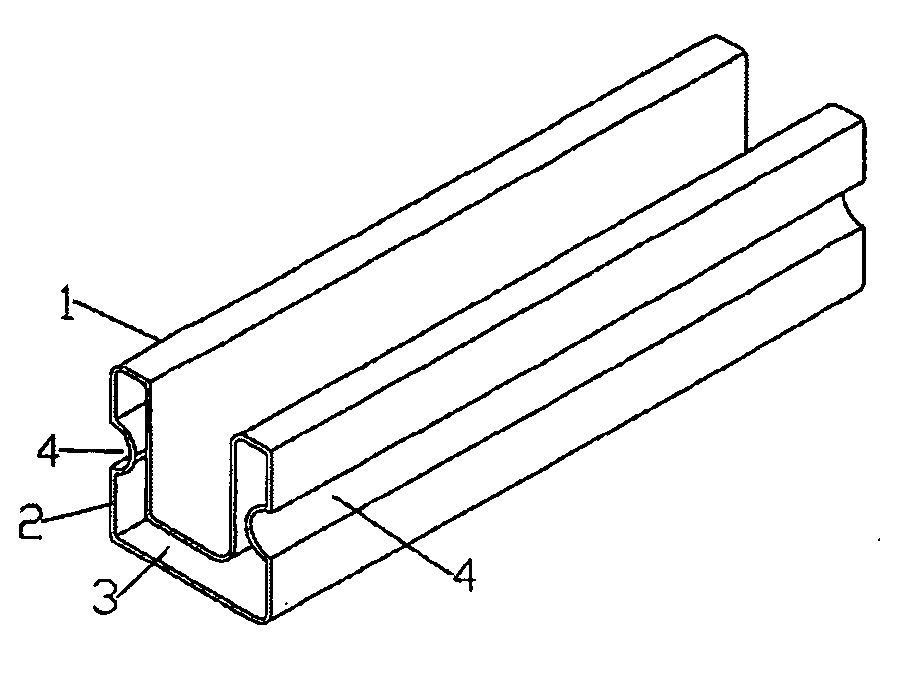

[0030]FIG. 2 illustrates the present invention, wherein the to corner protector, which is made of paper, comprises a corner reinforcement body 1 formed by folding a cardboard 2 edge-to-edge and defined an empty cavity 3 between two board walls of the corner reinforcement body 1. The corner reinforcement body 1 has a U-shaped cross section. The corner reinforcement body 1 further has a reinforcement bouncing groove 4 indently and longitudinally formed at each of the outer board walls of the corner reinforcement body 1 for preventing the deformation of the corner reinforcement body 1.

[0031]FIGS. 3 and 4 illustrate a third embodiment of the present invention as an alternative mode of the second embodiment, wherein the corner protector has a U-shaped cross section. One side longitudinal wall of the U-shaped corner reinforcement body 1 is higher than the opposed side longitudinal wall of the U-shaped corner reinforcement body 1. An indention slot 5 is formed between the two side longitud...

fourth embodiment

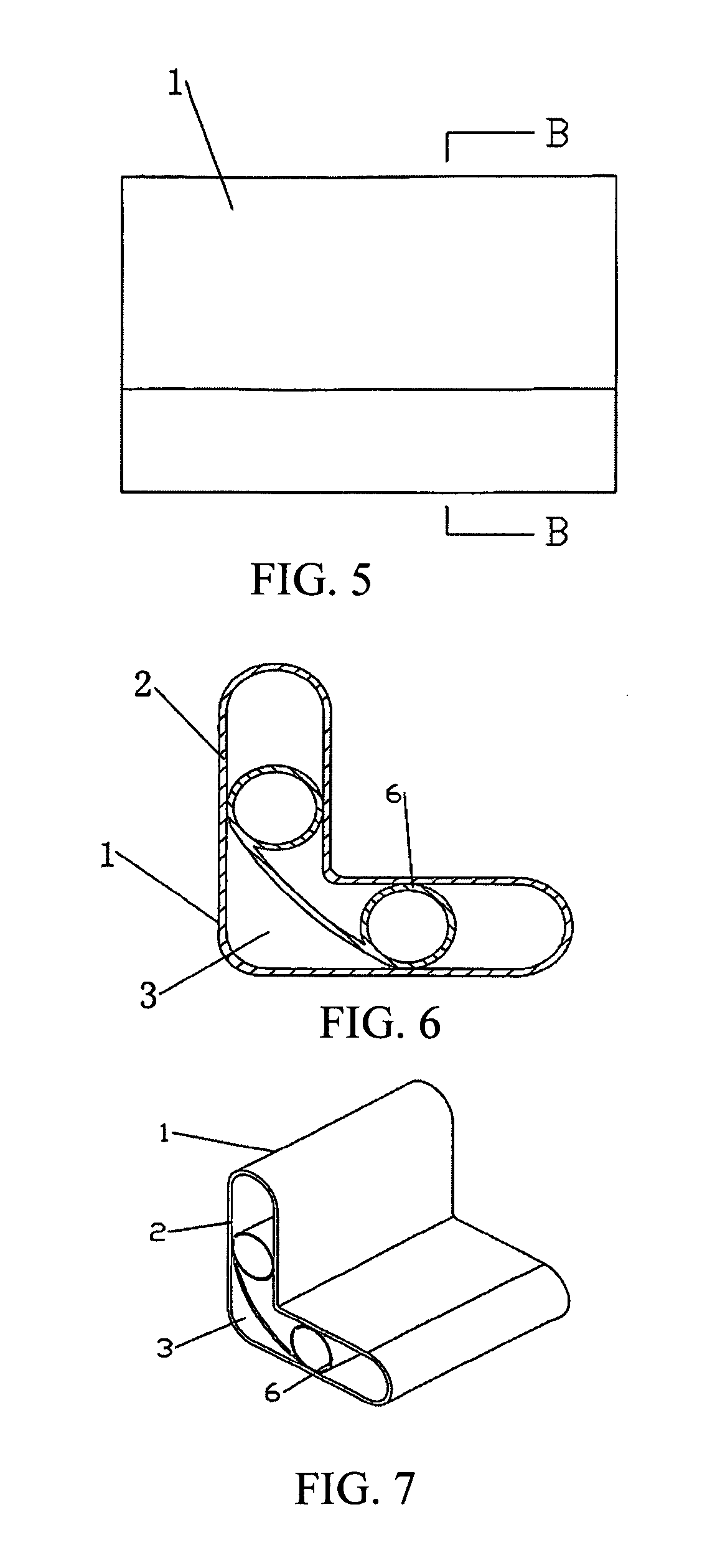

[0032]FIGS. 5, 6, and 7 illustrate the present invention, wherein the corner protector, which is made of paper, comprises a corner reinforcement body 1 formed by folding a cardboard 2 edge-to-edge and defined an empty cavity 3 between two board walls of the corner reinforcement body 1, such that the space between the two board walls is empty to form the cavity 3. The corner reinforcement body 1 has a L-shaped cross section. The corner protector further comprises at least one reinforcing bouncer 6 disposed within the cavity 3. The reinforcing bouncer 6 has a longitudinal tubular structure and is made of paper. For the corner reinforcement body 1 having a L-shaped cross section and defining an opposite portion and an adjacent portion to form a right angled configuration, two reinforcing bouncers 6 are applied to the L-shaped corner reinforcement body 1. The two reinforcing bouncers 6 are disposed within the cavity 3 of the corner reinforcement body 1 within the opposite portion and th...

fifth embodiment

[0033]FIGS. 8 and 9 illustrate the present invention, wherein the corner protector, which is made of paper, comprises a corner reinforcement body 1 formed by folding a cardboard 2 edge-to-edge and defined an empty cavity 3 between two board walls of the corner reinforcement body 1, such that the space between the two board walls is empty. The corner reinforcement body 1 has a L-shaped cross section. The reinforcement bouncing groove 4, having a curved shape, is indently and longitudinally formed at each of the outer board walls of the corner reinforcement body 1 for preventing the deformation of the corner reinforcement body 1. The apex of the reinforcement bouncing groove 4 is arranged to bias against the inner board wall for applying a bouncing force against the inner board wall to retain a distance between the outer and inner board walls.

[0034]One skilled in the art will understand that the embodiment of the present invention as shown in the drawings and described above is exempl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com