Shower pan drain assembly system

a technology of shower pan and drain pipe, which is applied in the direction of water installations, douches, sewerage structures, etc., can solve problems such as leakage, and achieve the effect of preventing clogging of weep holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

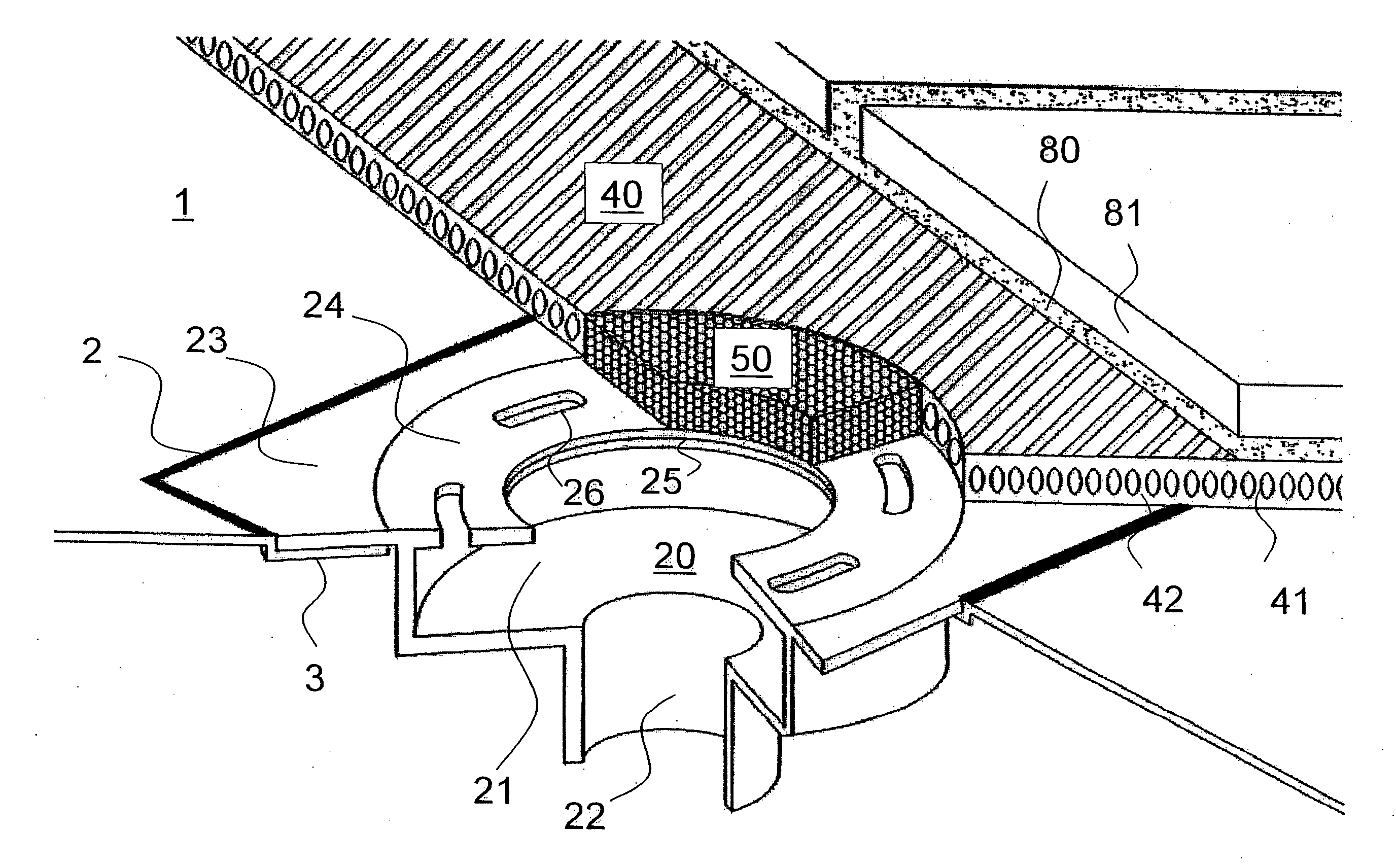

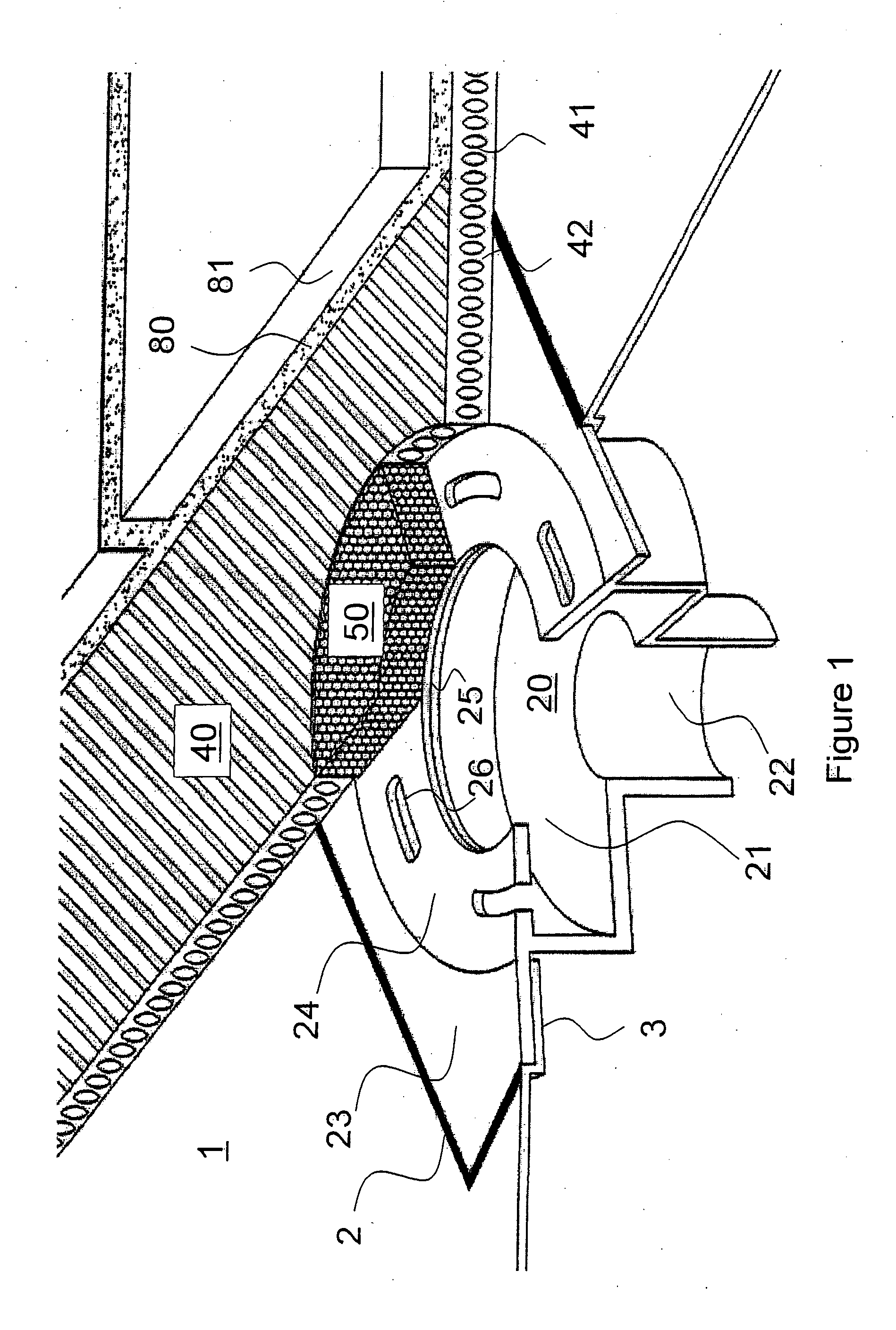

[0041]Referring initially to the present invention as presented in FIG. 1, the preferred embodiment is shown using cross sections of the different components. FIG. 1 displays the integrated floor drain 20 connected to the shower pan 1 with a mortar guard 50 and drainage mat 40 resting on top of the floor drain 20 and shower pan 1. The mortar 80 and tile or stone 81 is then applied as another layer resting on top of the mortar guard 50 and drainage mat 40. Tile 81, including but not limited to ceramic tile and stone 81, including but not limited to marble, granite or composite, is used in the preferred embodiment of the invention.

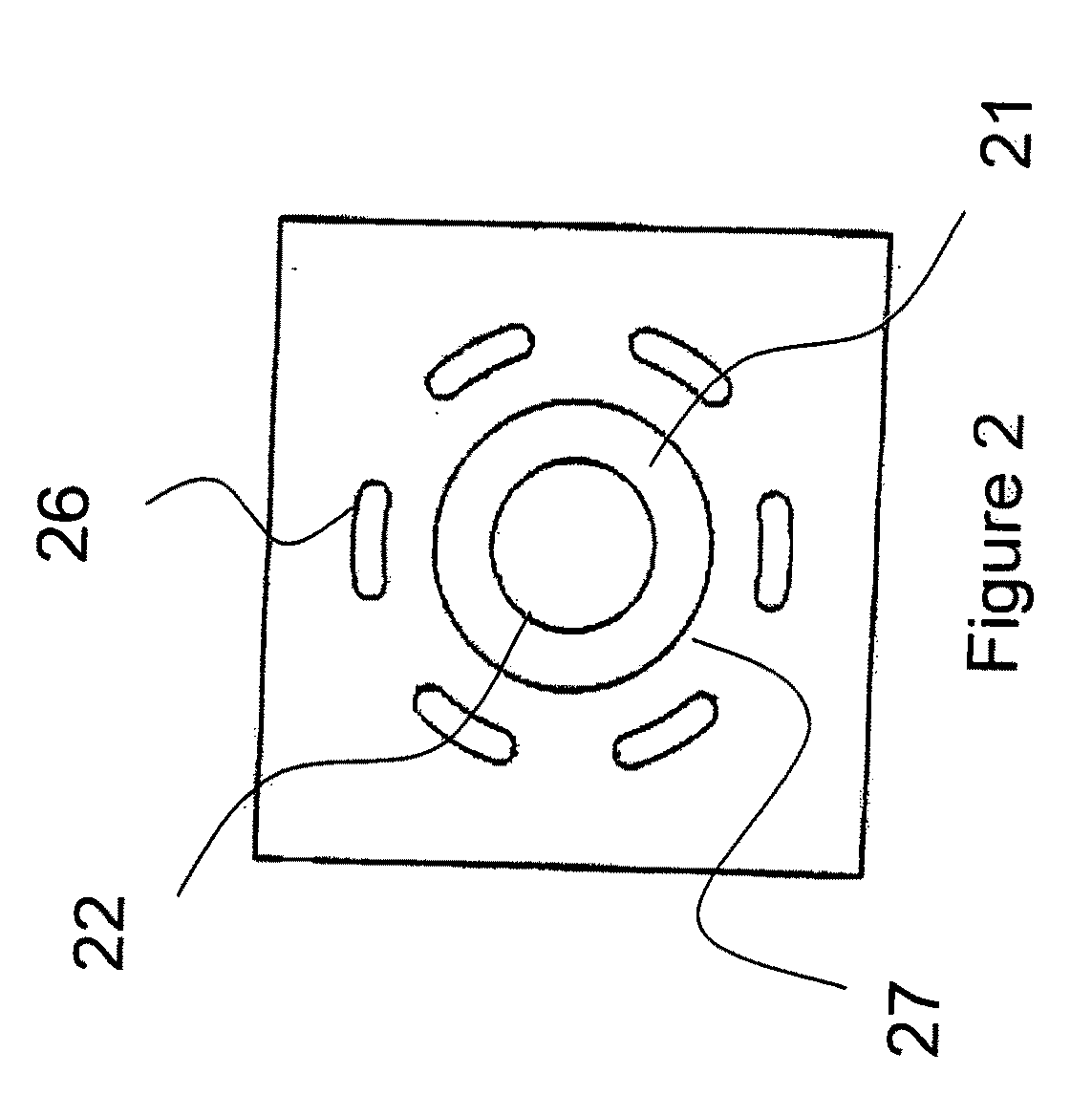

[0042]The integrated floor drain 20 is composed of two sections, the reservoir 21 and the drain pipe 22. The drain pipe 22, as depicted, is a cylindrical tube formed by a circular side wall with openings at both ends. One end connects to the plumbing system. At the other end, an edge extends outwardly from the drain pipe 22 forming a wider reservoir 21 to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com