Recloseable package with protective patch

a technology of protective patch and package, applied in the direction of flexible covers, containers, sacks, etc., can solve the problem of reducing the amount of time it takes to change an existing printed packaging over to a new reclosable packaging graphic, and achieve the effect of reducing the amount of time it takes and eliminating tear propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]While the present invention is susceptible of embodiment in various forms, there is shown in the drawings and will hereinafter be described a presently preferred embodiment of the invention, with the understanding that the present disclosure is to be considered as an exemplification of the invention, and is not intended to limit the invention to the specific embodiments illustrated.

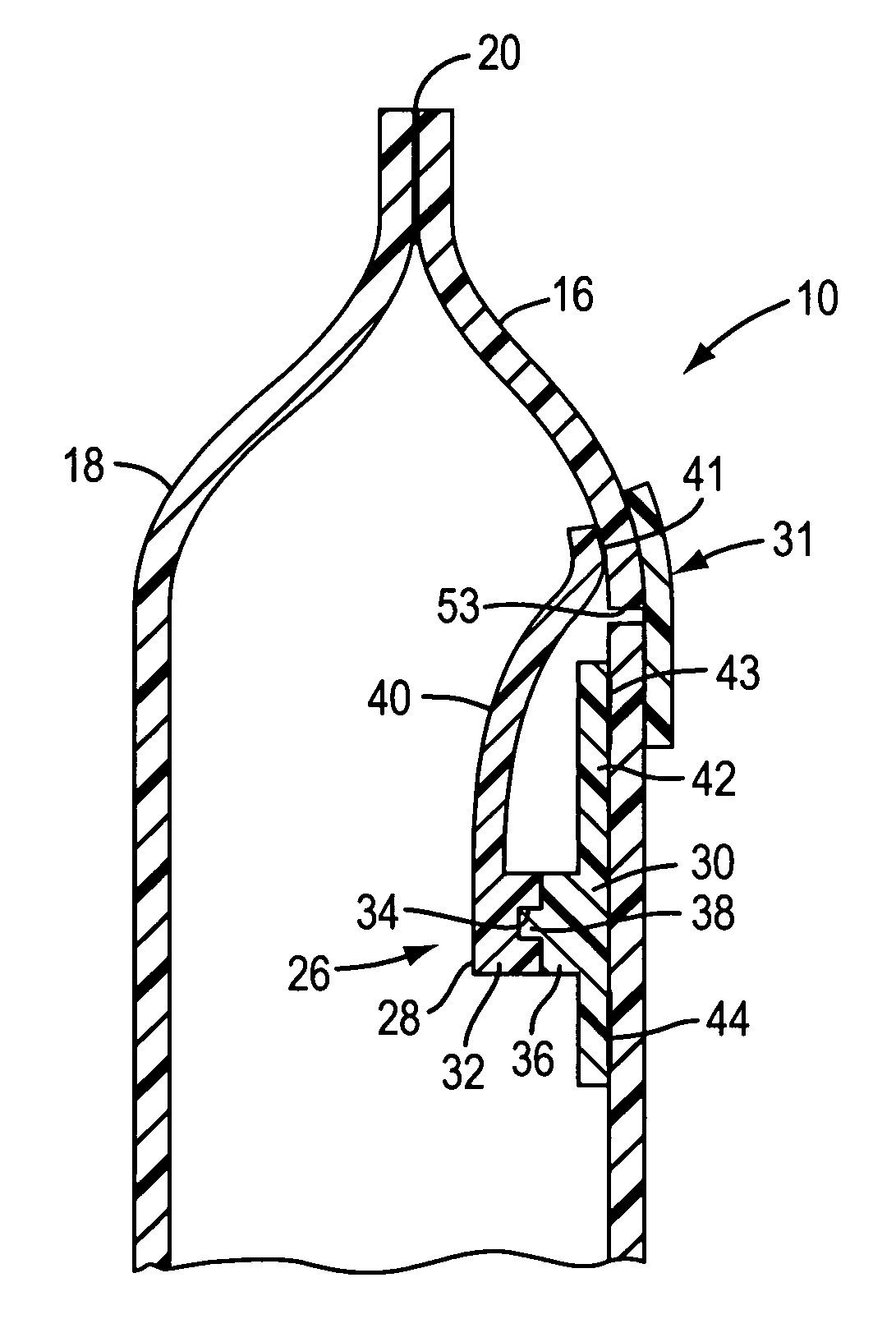

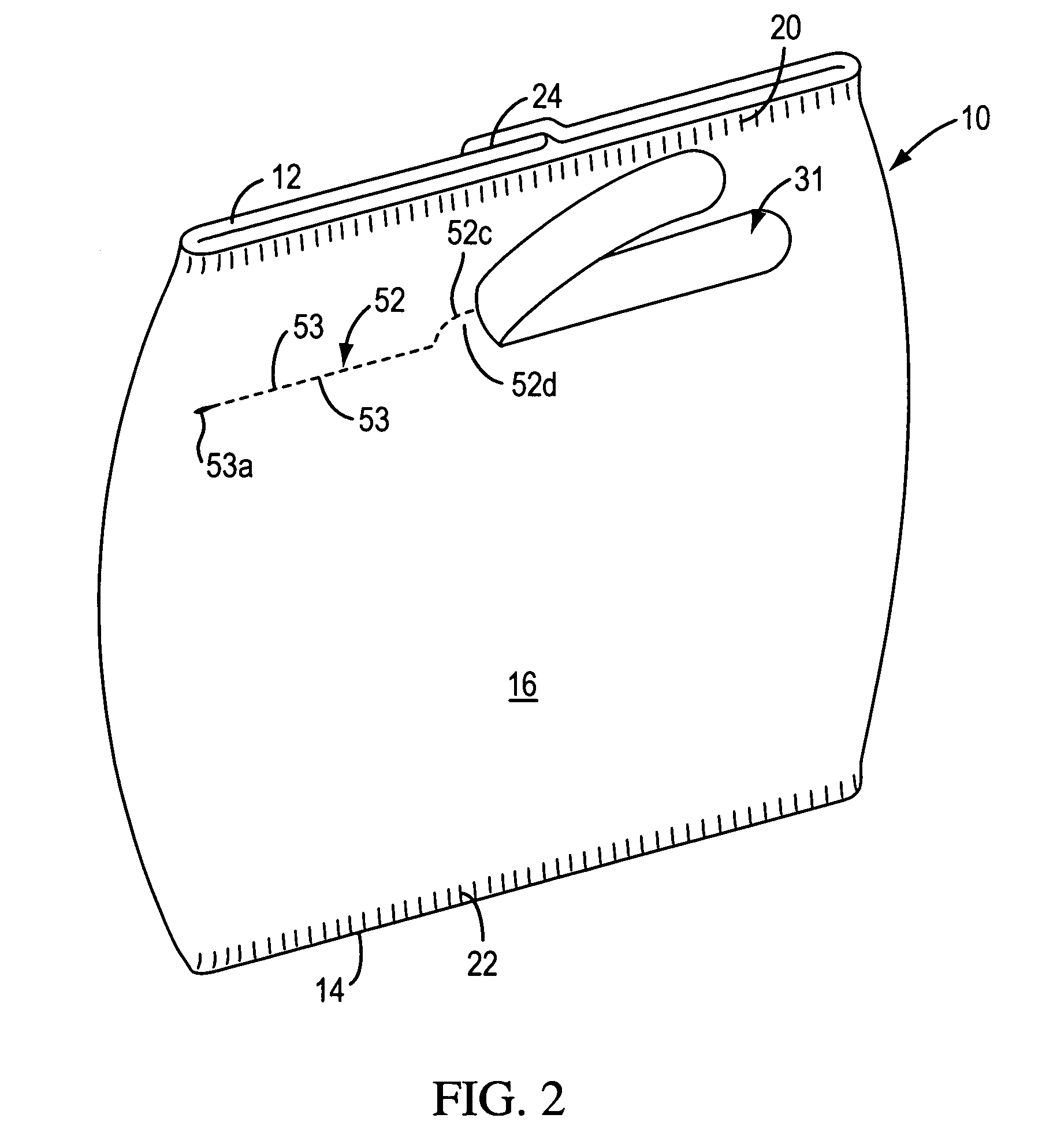

[0023]With reference now to the drawings, a package in the form of a reclosable bag 10 is illustrated which embodies the principles of the present invention. It is contemplated that the bag 10 be formed from suitable plastic film materials or the like, but it is within the purview of the present invention to form the bag from paper or paper-like materials. As will hereinafter be described, bag 10 is specifically configured in a manner which facilitates formation of the bag from a substantially continuous web of film material, to which fastener assemblies have been previously applied, for use in a so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com