Cleaner head assembly for a vacuum cleaner

a vacuum cleaner and cleaning head technology, which is applied in the direction of suction cleaners, cleaning equipment, suction nozzles, etc., can solve the problems of not maintaining good contact between the cleaning head and the surface to be cleaned, the cleaning head cannot maintain good contact in both directions, and the cleaning head cannot move away from the optimal, so as to improve the ability of the cleaning head to pick up debris and improve the sealing of the suction opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

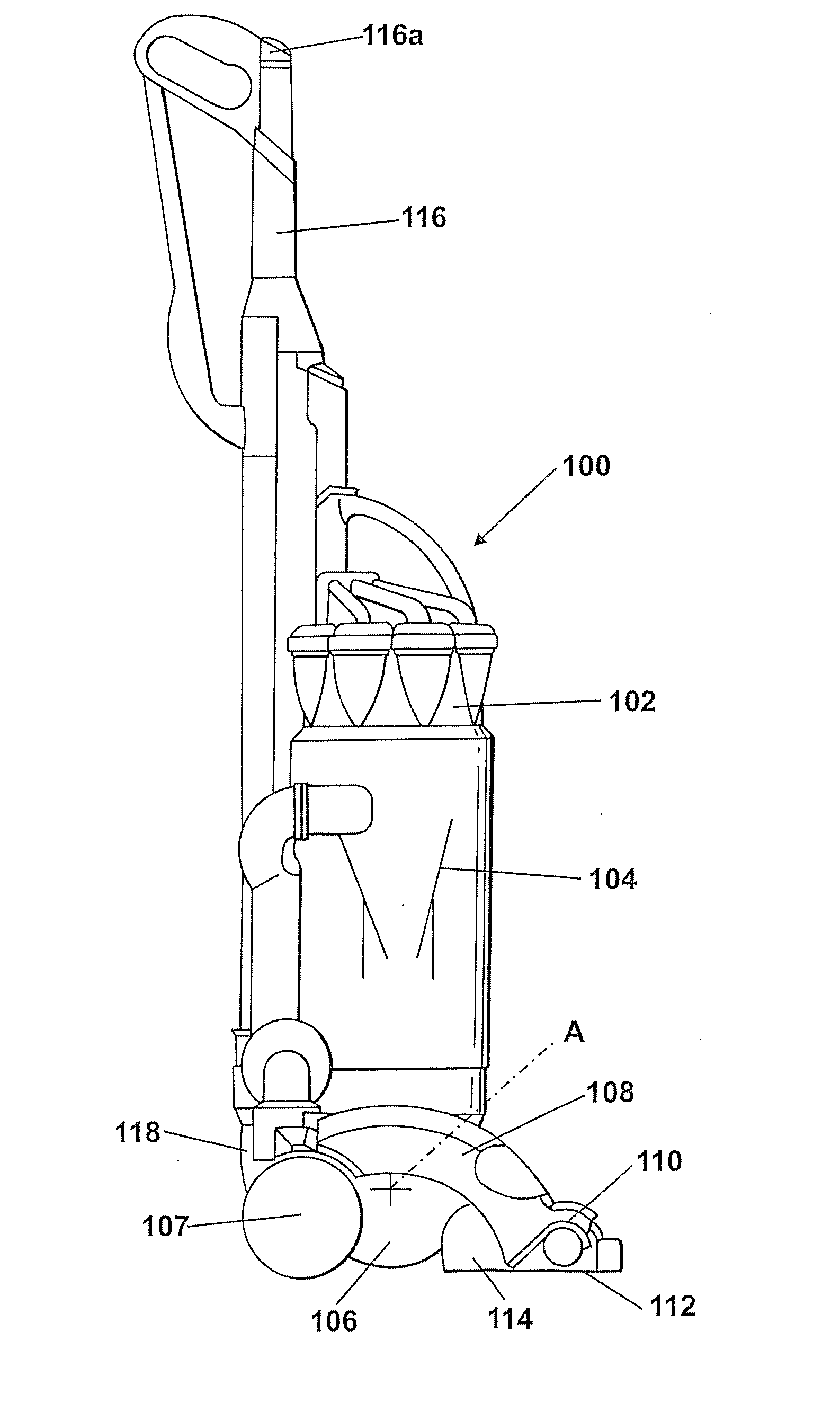

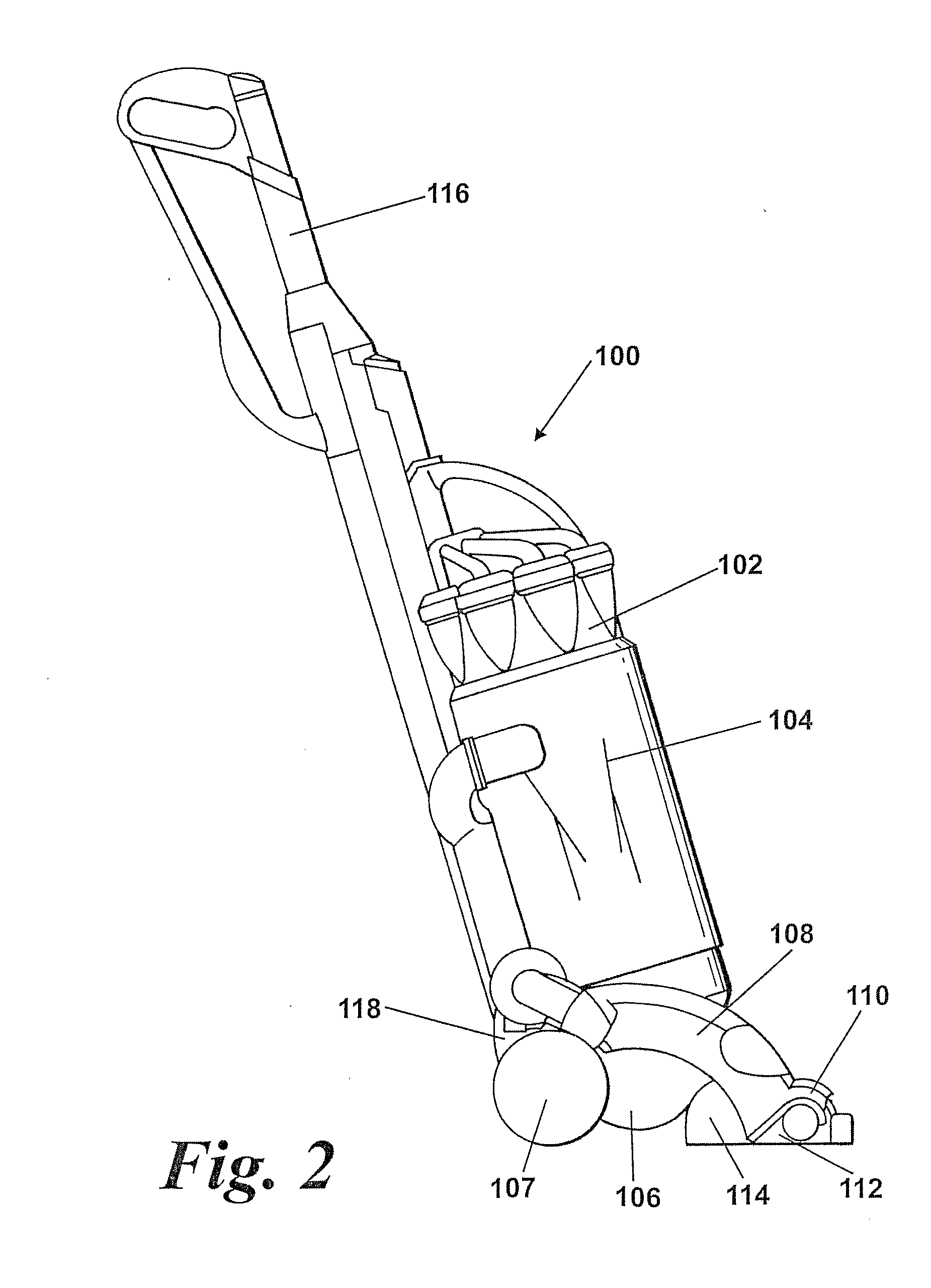

[0025]FIGS. 1 and 2 illustrate the overall construction of an upright vacuum cleaner incorporating a cleaner head assembly according to the invention. The vacuum cleaner 100 has a main body 102 in which dust separation apparatus 104 is housed. In FIGS. 1 and 2 the dust separation apparatus 104 is shown schematically. The embodiment may comprise cyclonic dust separation apparatus consisting of two cyclones arranged in series. Apparatus of this type is well known and will not be described any further here because it has no material effect on the invention. A motor housing 106 is located at the lower end of the main body 102 and forms part of the main body 102. Supporting wheels 107 are mounted directly on the side of the motor housing 106. A cleaner head assembly 108 is rotatably mounted on the motor housing 106 about an axis A. The cleaner head assembly 108 has a brush housing 110 with a downward facing inlet 112 arranged at the forward end of the cleaner head assembly 108. A brush b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com