Disposable and ambidextrous glove sander

a glove sander, ambidextrous technology, applied in the field of hardware supplies, can solve the problems of insufficient leverage or grip, cumbersome use of sandpaper sheets, and inability to find sufficient leverage or grip for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]According to a preferred embodiment of the present invention, a unique article of manufacture or device is used to finish wooden articles or other products to make them smoother and remove rough edges. The present invention is also adaptable to finish other surfaces other than wood. Moreover, the present invention is an improvement to a pending patent application. The article of manufacture or device is described in enabling detail below.

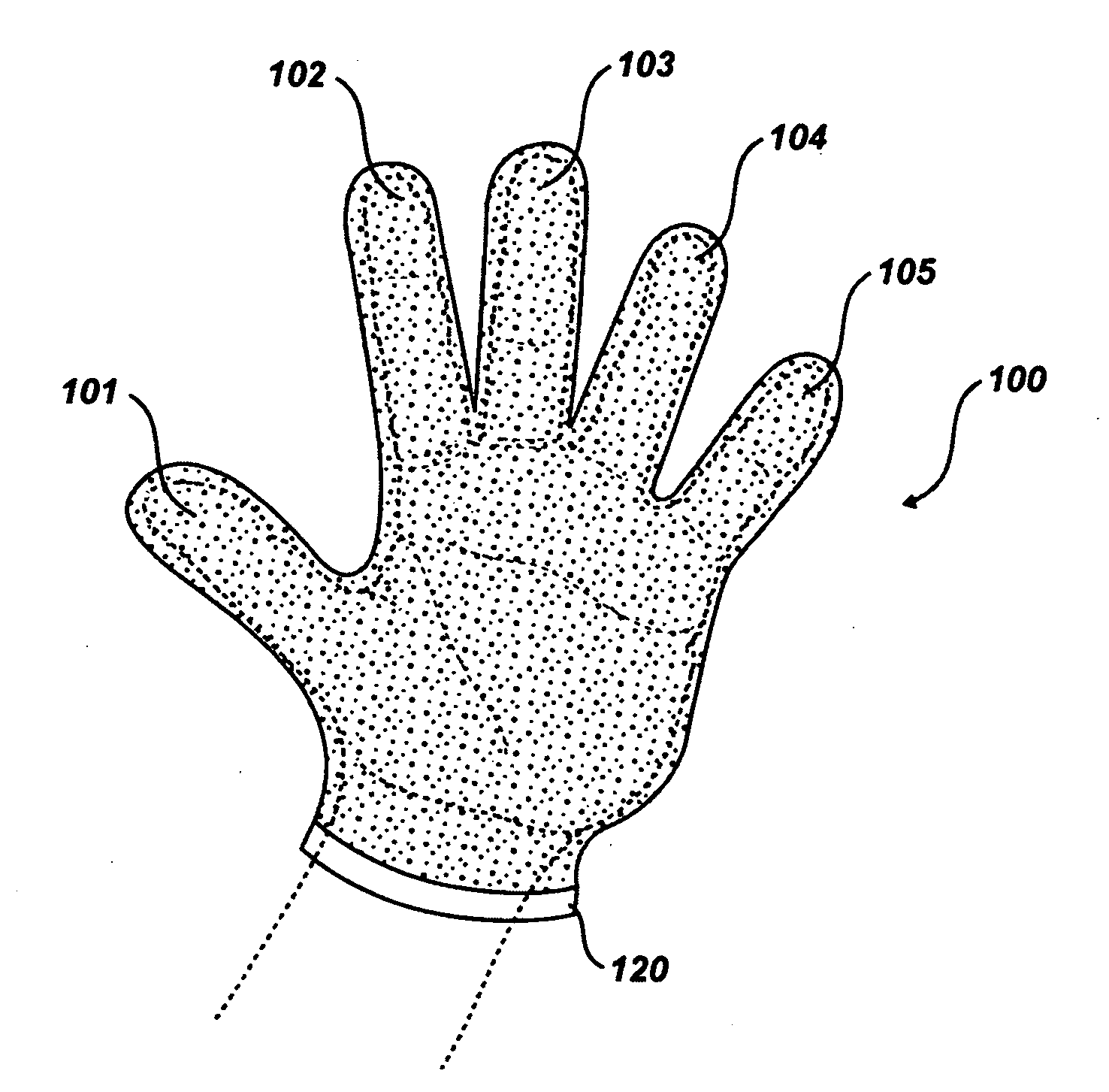

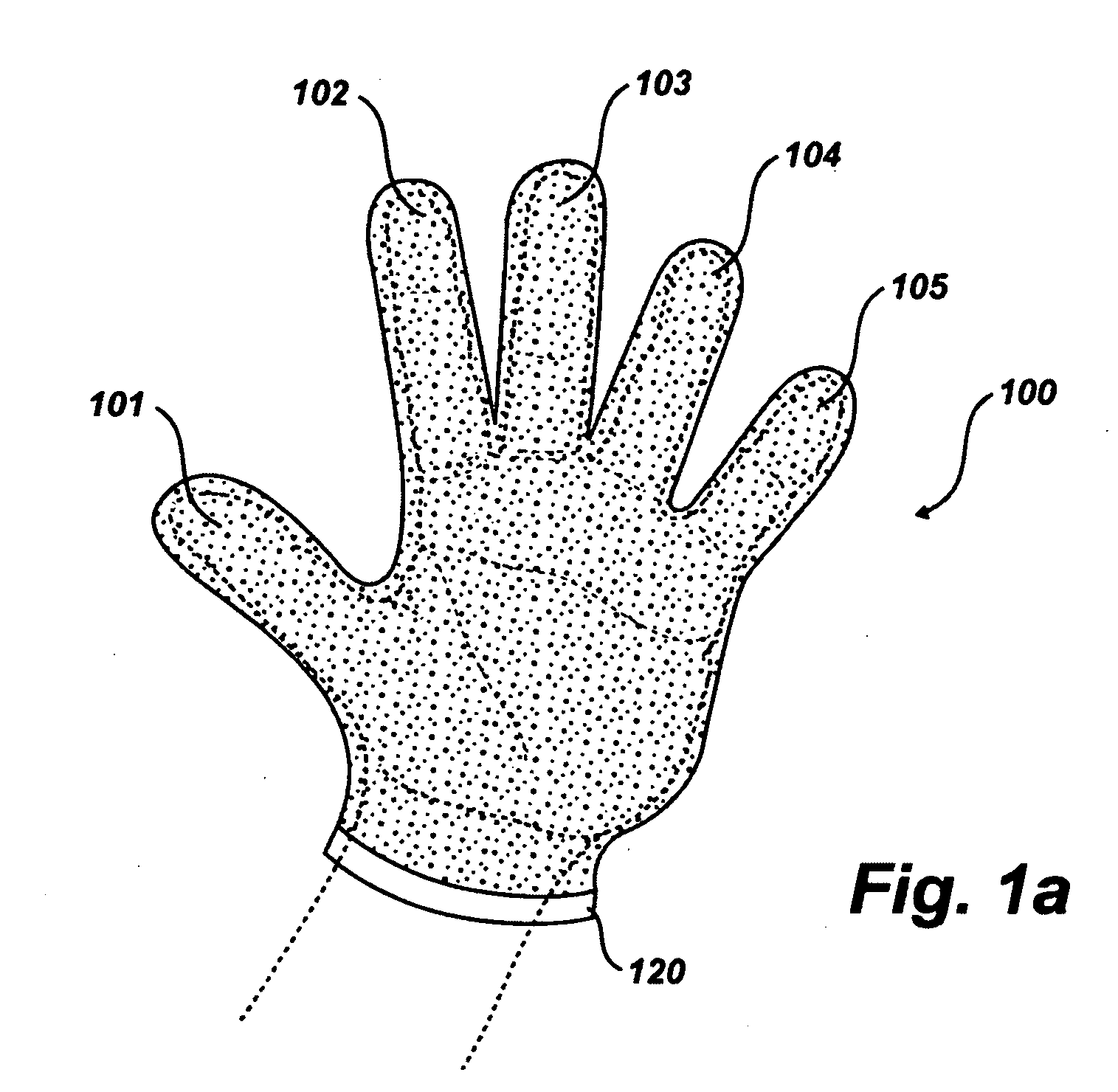

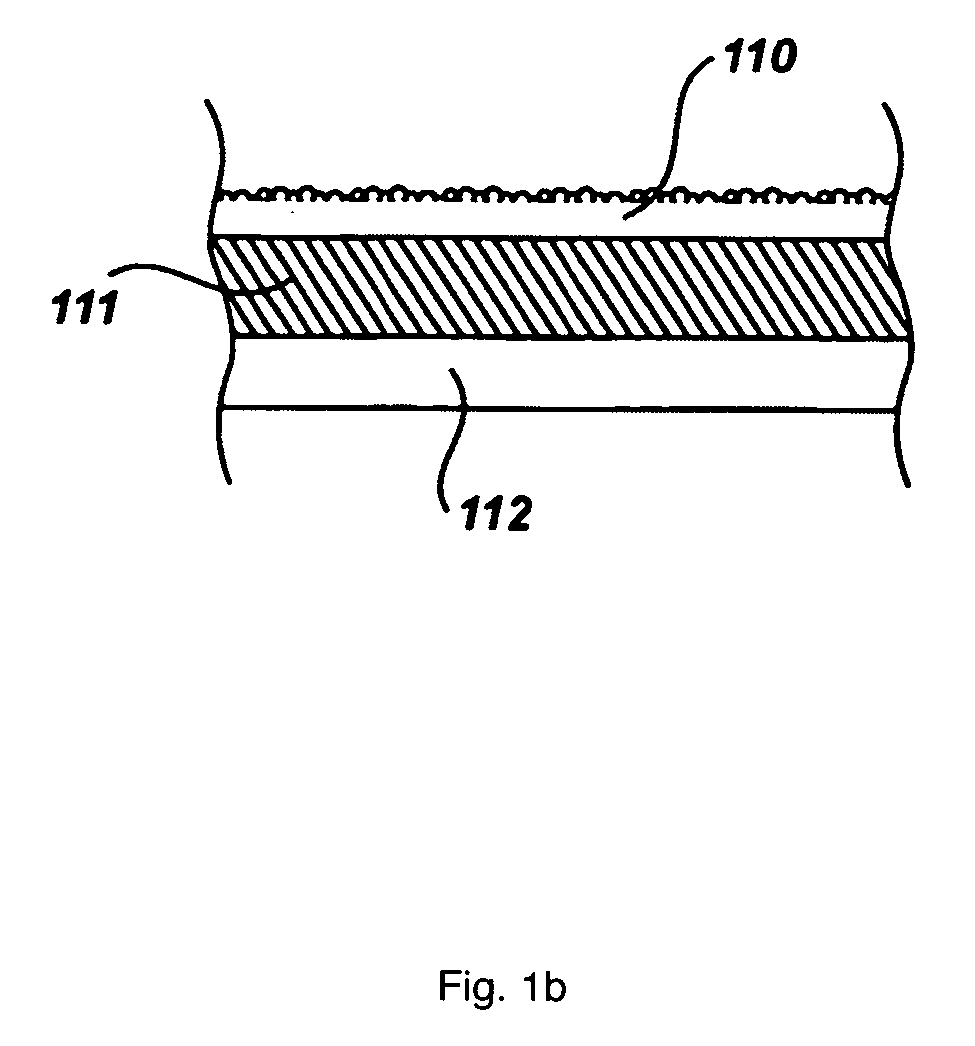

[0023]FIG. 1a illustrates a preferred embodiment of the present invention. The disposable and ambidextrous glove sander 100 (hereafter Glove Sander) is will be described herein by specific enumerated regions or parts. Although the present invention will be described by different regions or parts it should be understood that these individual component-regions are not necessarily separately manufactured pieces or components. The nomenclature and enumeration of the regions, parts, or components thereof are only for illustrative purposes and are n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com