Method to construct and physically join building blocks into a near-net shaped part using an interfacial reaction-activation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

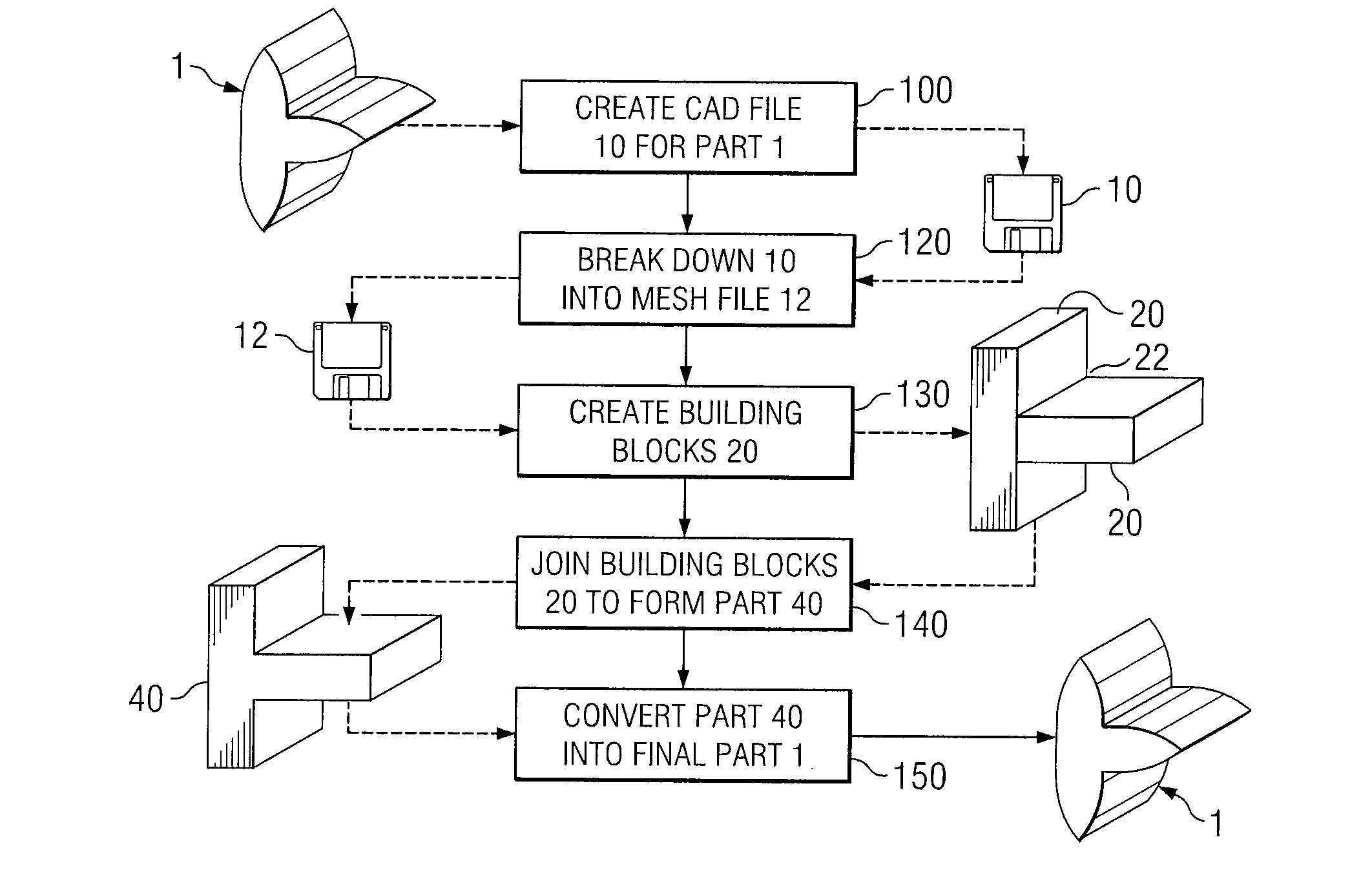

[0009]Preferred embodiments of the disclosure and its advantages are best understood by reference to FIGS. 1-3 wherein like numbers refer to same and like parts.

[0010]The manufacture of components, whether for small or large systems, simple or complicated devices, and large or small scale runs, includes multiple cost factors. In any manufacturing process that involves machining parts, there are at least two factors that contribute to the overall cost of the part. Depending on the part at issue, the majority of its cost may be connected to the machine time required to complete the part. In other systems, it is the cost of the raw material that dominates the total cost.

[0011]A process that provides reduction in overall cost is always of interest. For instance, a process to manufacture components for complicated systems, such as large-scale aircraft components, that shortens machine time results in large savings. In addition, less waste material results in savings, especially in system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Shape memory effect | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com