Ir camera and method for use with ir camera

a technology of ir camera and focal plane array, which is applied in the field of ir camera, can solve the problems of reducing the image quality of ir camera, increasing the power consumption and manufacturing cost of the focal plane array, and different pixels showing slightly different temperature dependent behaviour. , to achieve the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

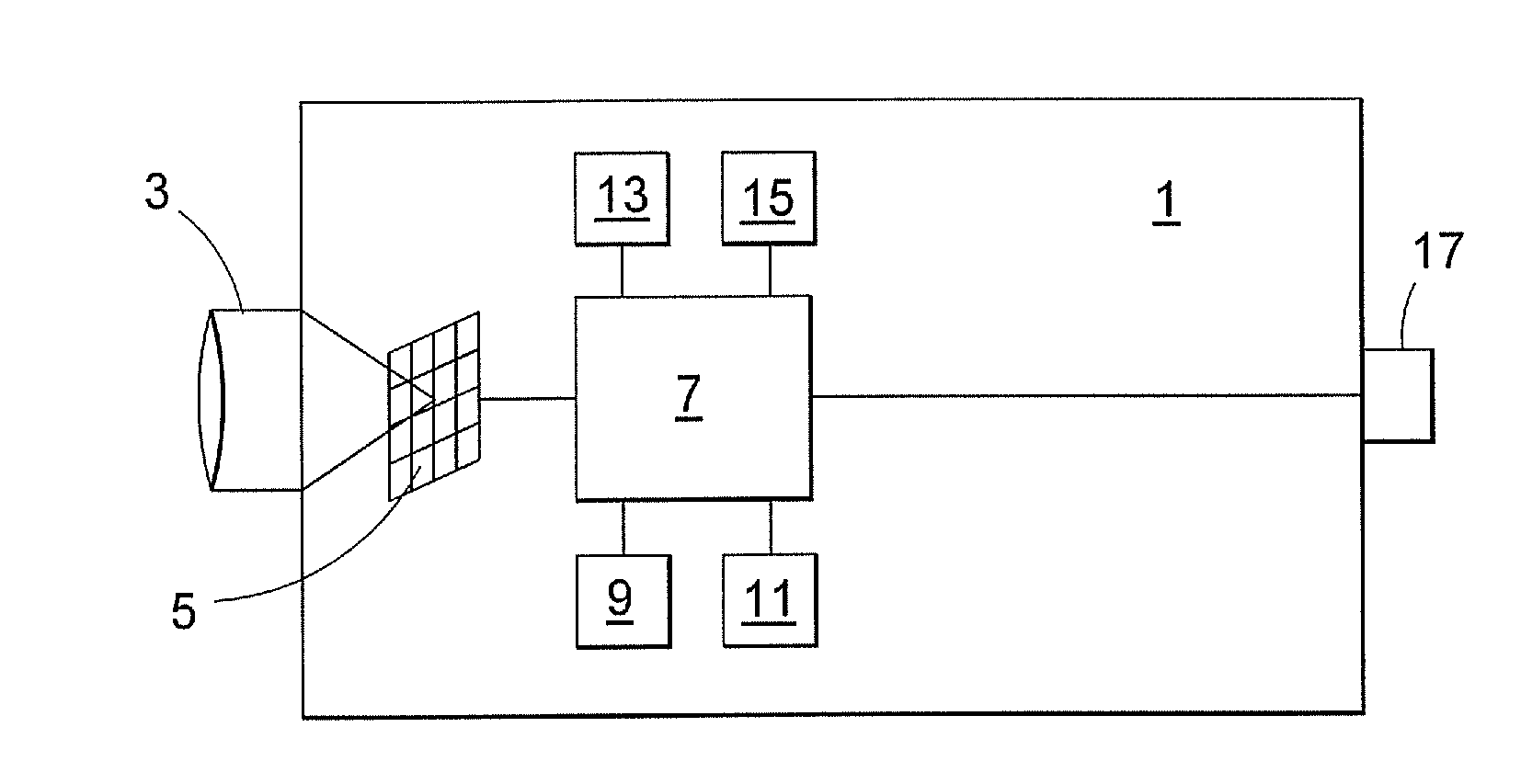

[0046]FIG. 1 illustrates an IR camera 1 in which the functions according to the invention may be implemented. The IR camera comprises IR optics 3 for focusing incoming radiation in the IR range onto a focal plan array 5 comprising a number of pixels, each arranged to produce an output signal in dependence of the incoming radiation.

[0047]The output signal from each pixel is fed to a processing unit 7 arranged to perform conventional processing on the signals. According to the invention, the processing unit 7 is also arranged to perform certain functions during calibration of the camera during manufacturing. The processing unit 7 is also arranged to perform certain compensation procedures during operation of the camera, to compensate for the temperature variations of the camera. According to an embodiment of the invention these compensation procedures differ from those common in the art, to take into account that the camera does not have calibration parameters for different ambient te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com