Auto-igniter for biomass furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

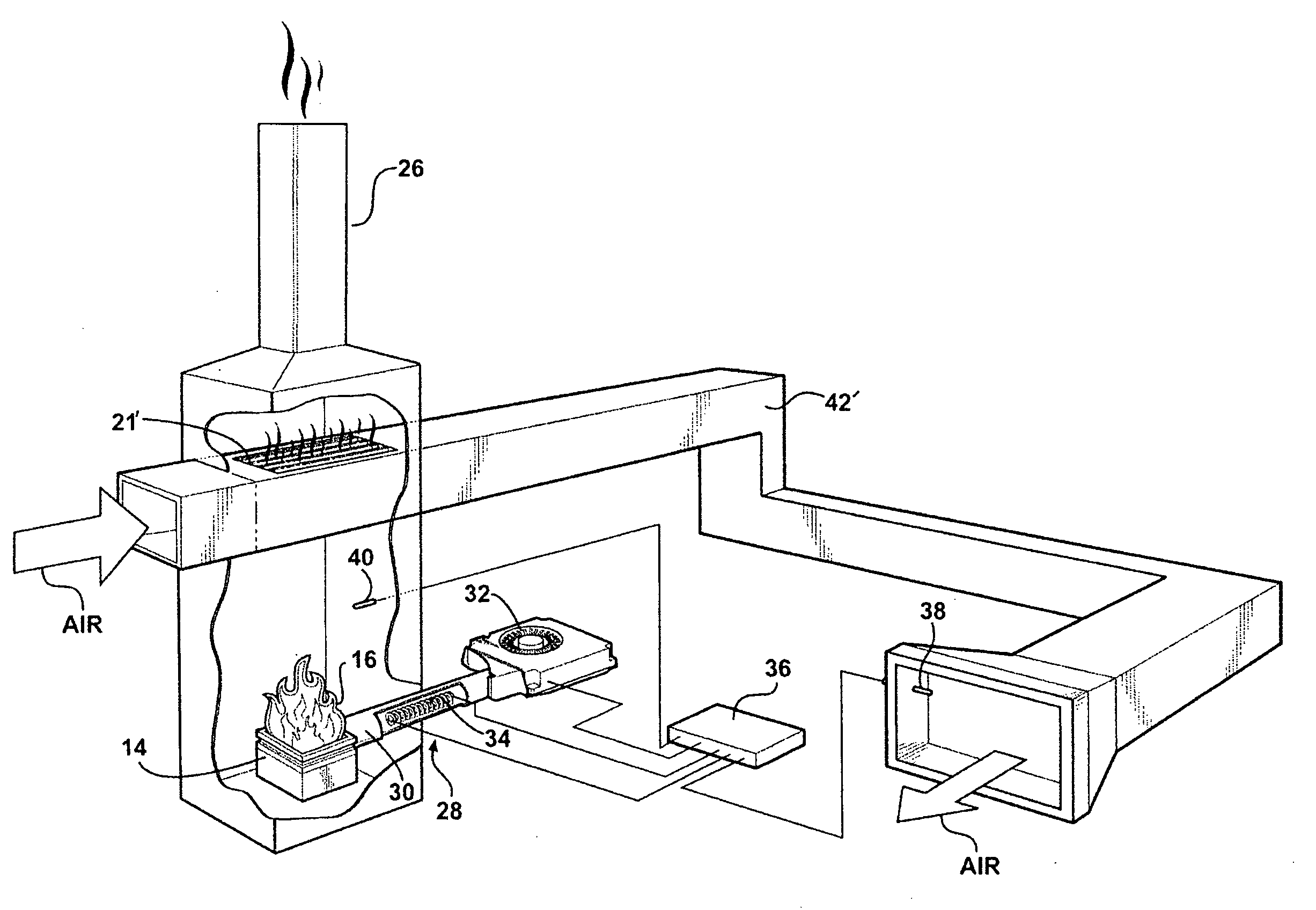

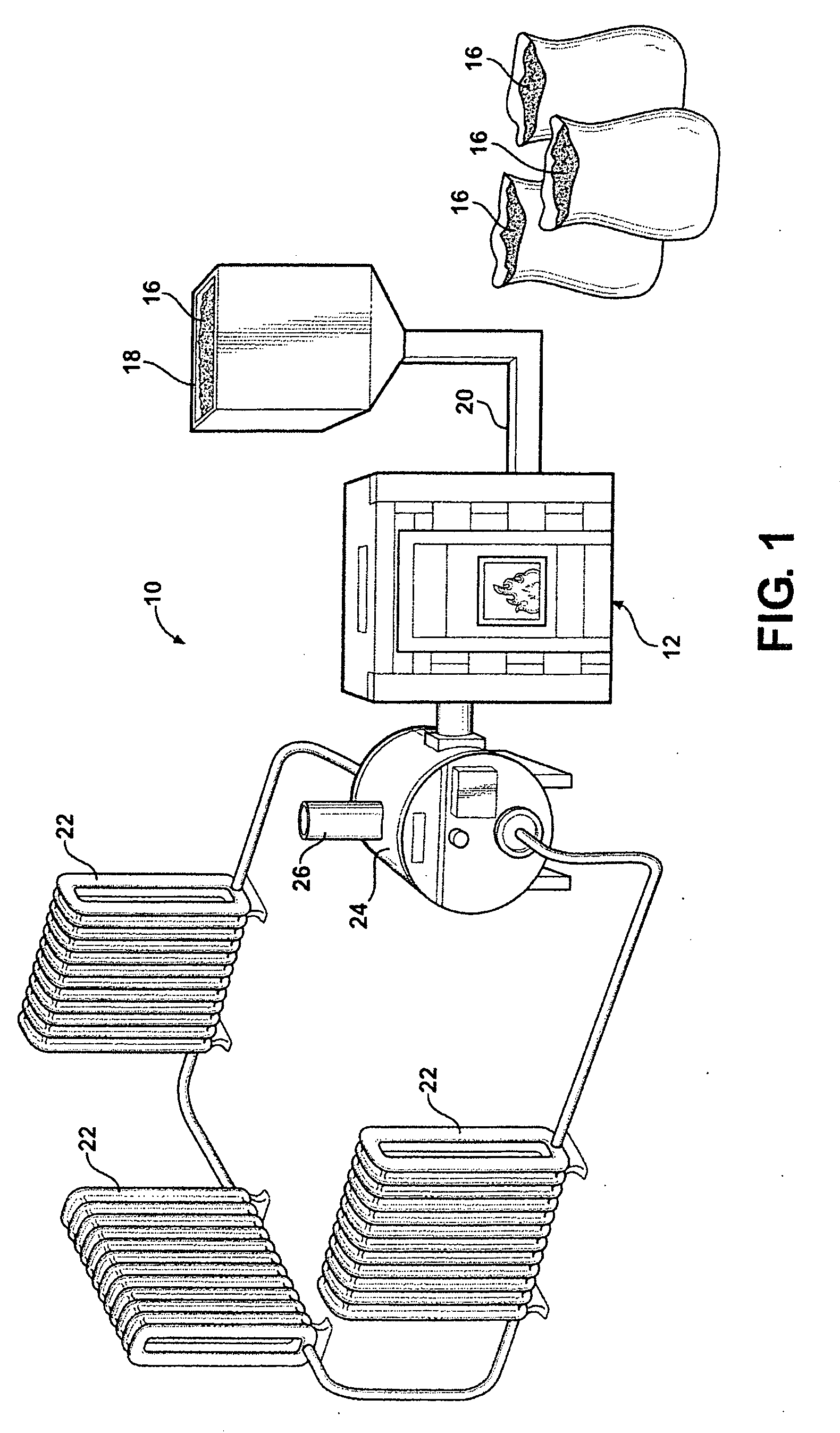

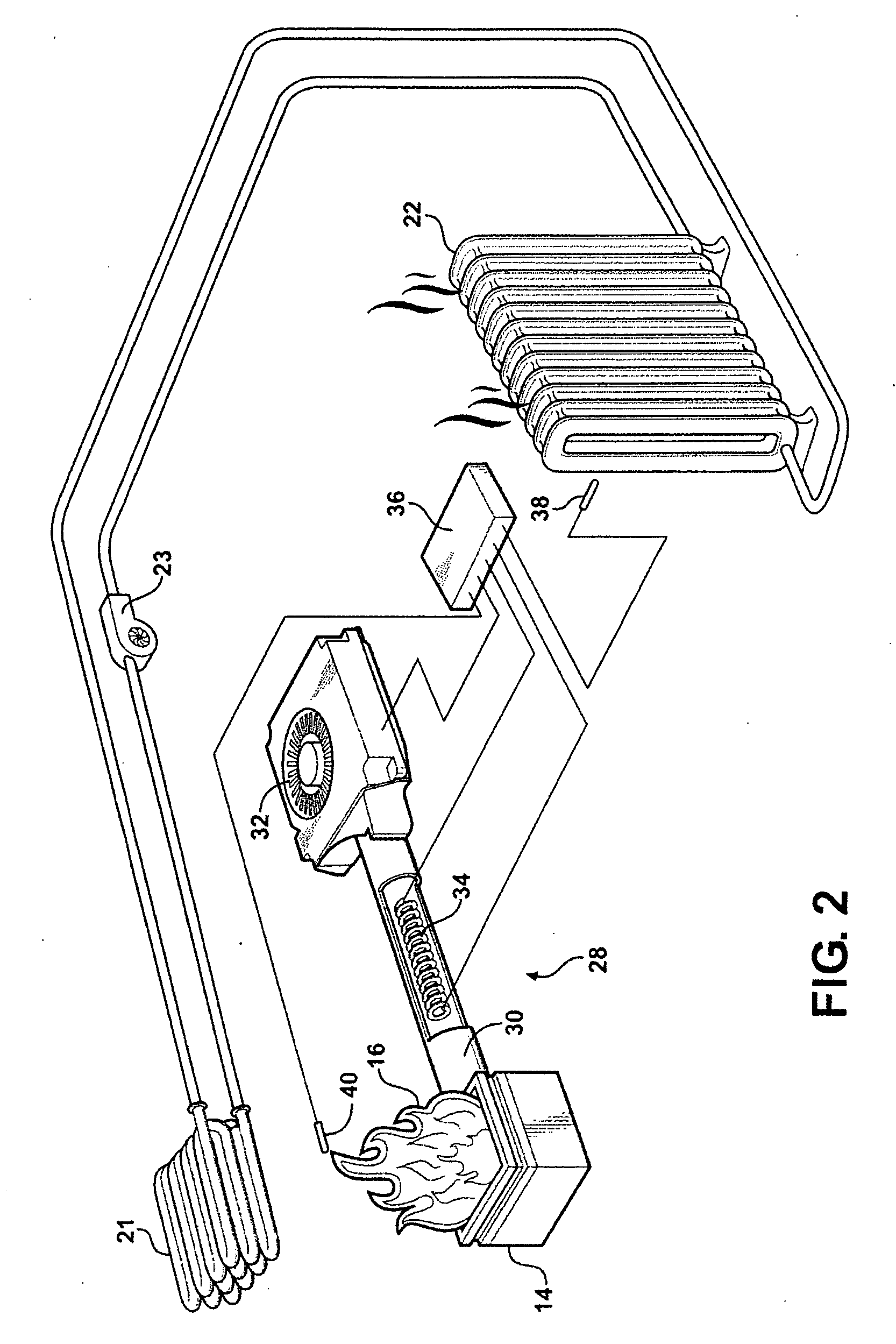

[0021]Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, FIG. 1 schematically illustrates a heating system, generally shown at 10. The heating system 10 includes a biomass furnace, generally indicated at 12, which in this instance is of the boiler variety. However, it will be understood that the biomass furnace 12 could be configured to run as a forced air type heating unit, or a stand-alone stove, or other type of arrangement. The biomass furnace 12 includes a combustion chamber 14, which is perhaps best shown in FIGS. 2 and 3. The combustion chamber 14, sometimes referred to as a burn pot, receives incremental quantities of biomass fuel 16 which, in FIG. 1, are illustrated in bushel sacks. The biomass fuel can be any of the known varieties, including pelletized wood, corn, soybeans, cherry pits, switchgrass, etc. The furnace 14 will include some type of hopper 18, shown here as a distended unit, into which the fuel 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com