Reduced eccentricity guardrail post connector for decking structure

a technology of eccentricity and connector, applied in the direction of structural elements, building components, building repairs, etc., can solve the problems of limiting the strength of the connection, the presence of eccentric moments, and the typical connection used to connect guardrail posts to wood framed decks that fail to meet this requirement, so as to prevent the splitting of the joist material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Although the following detailed description contains many specifics for the purposes of illustration, anyone of ordinary skill in the art will readily appreciate that many variations and alterations to the following exemplary details are within the scope of the invention. Accordingly, the following preferred embodiment of the invention is set forth without any loss of generality to, and without imposing limitations upon, the claimed invention.

[0021]A device enabling easy and correct assembly of deck railing posts to a deck base while supplying substantial support is provided. A method of fabricating the device is disclosed.

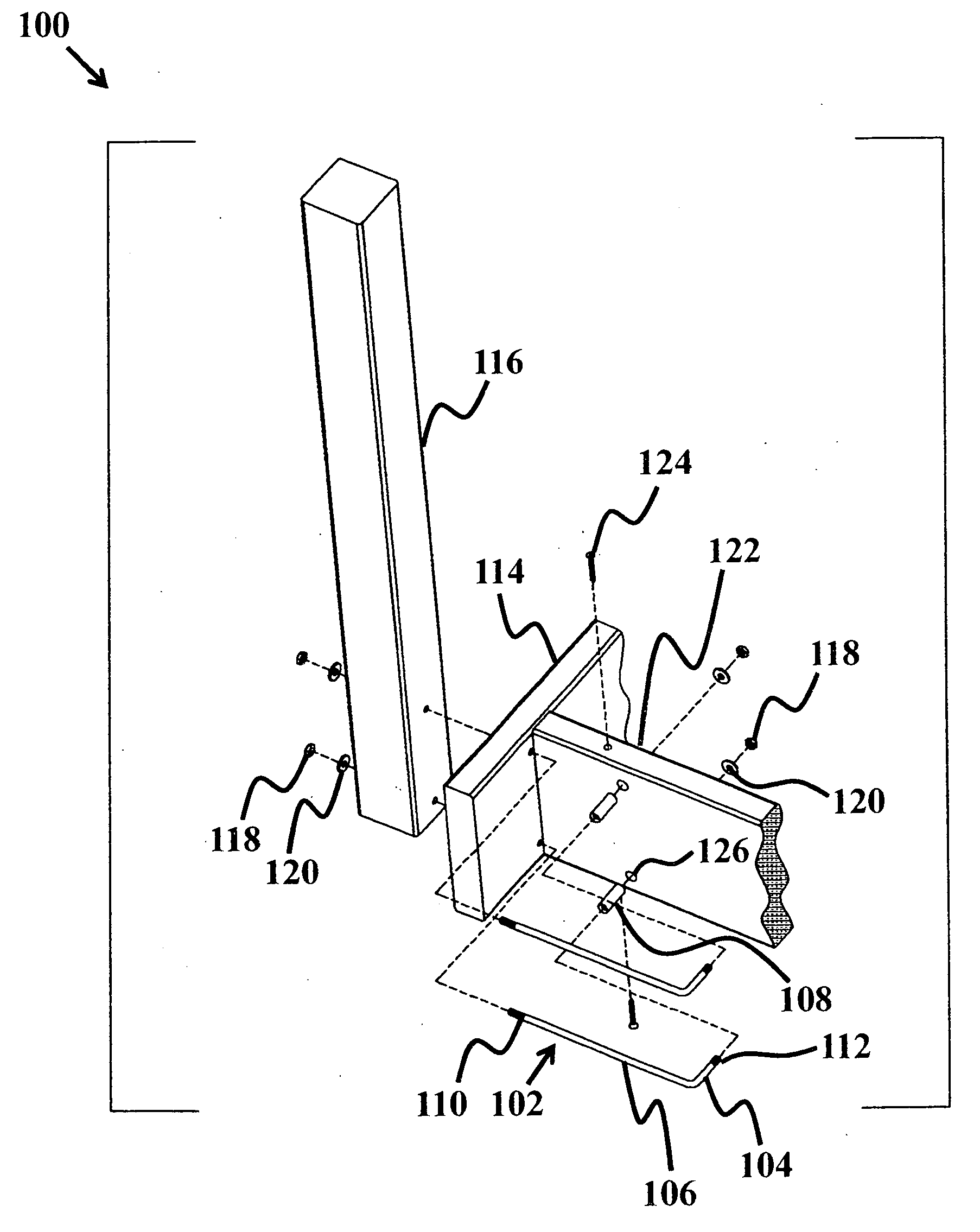

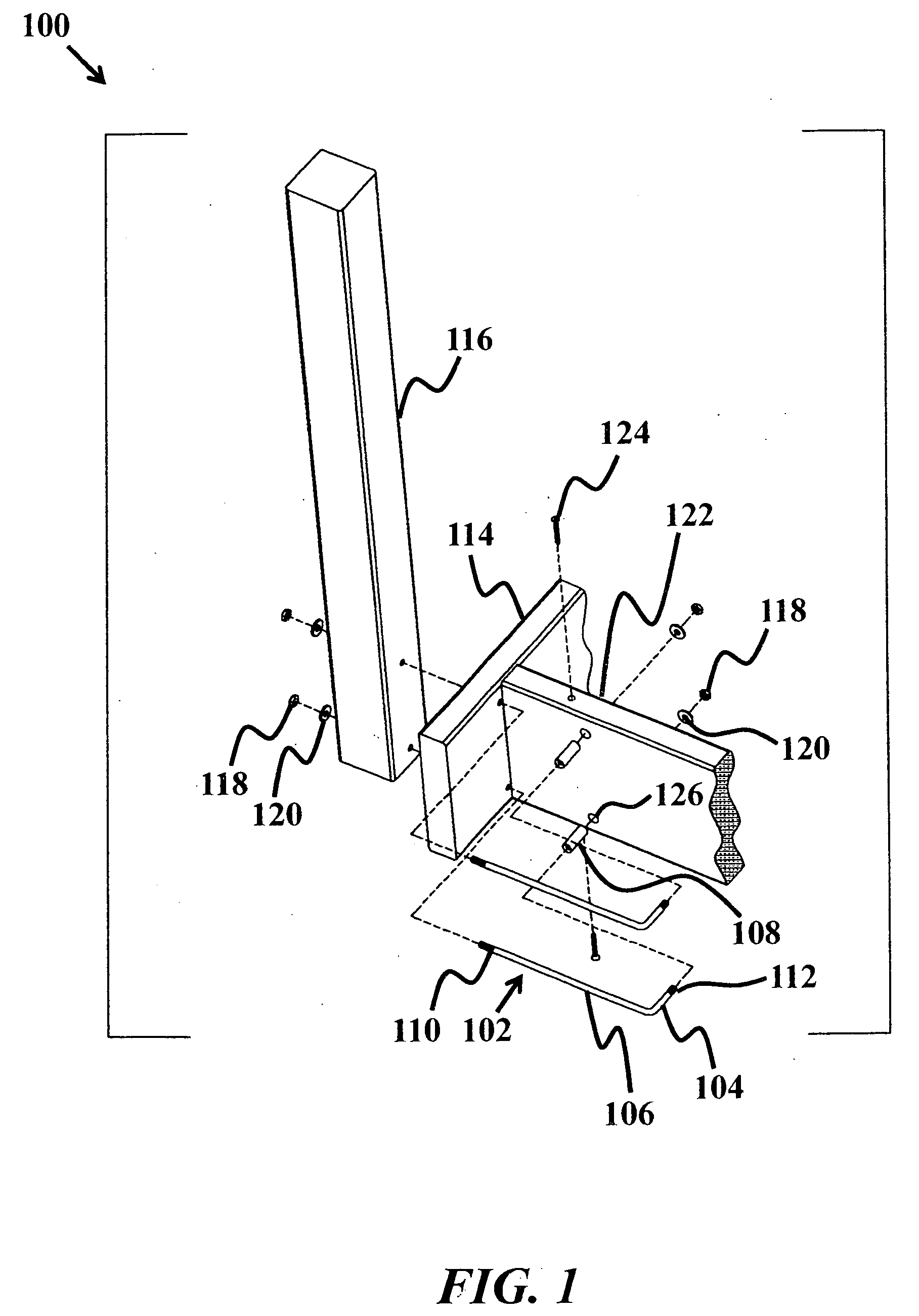

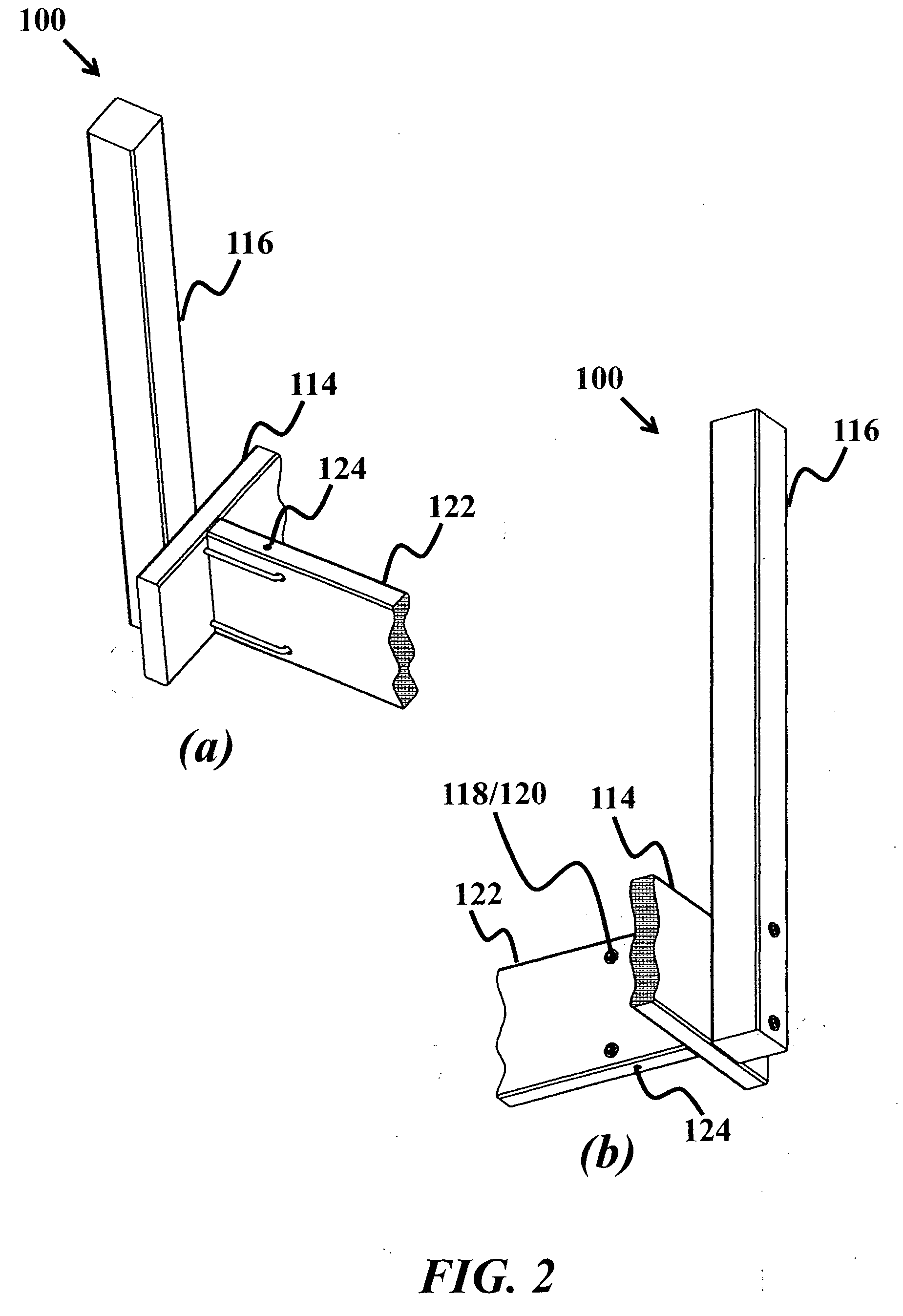

[0022]FIG. 1 shows an exploded perspective cutaway view of the guardrail post connector assembly 100 according to one embodiment of the current invention. This embodiment includes a connector rod 102 having a shear connection section 104 and a tension connection section 106, where the tension connection section 106 is disposed at approximately a normal angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com