Aluminum electrolysis cell electrolyte containment systems and apparatus and methods relating to the same

a technology of electrolysis cell and electrolyte, applied in the direction of electrolysis components, chemistry apparatus and processes, separation processes, etc., can solve the problems of significant heat loss and loss of ledges, and achieve the effect of facilitating the operation of electrolysis cells and avoiding ledges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

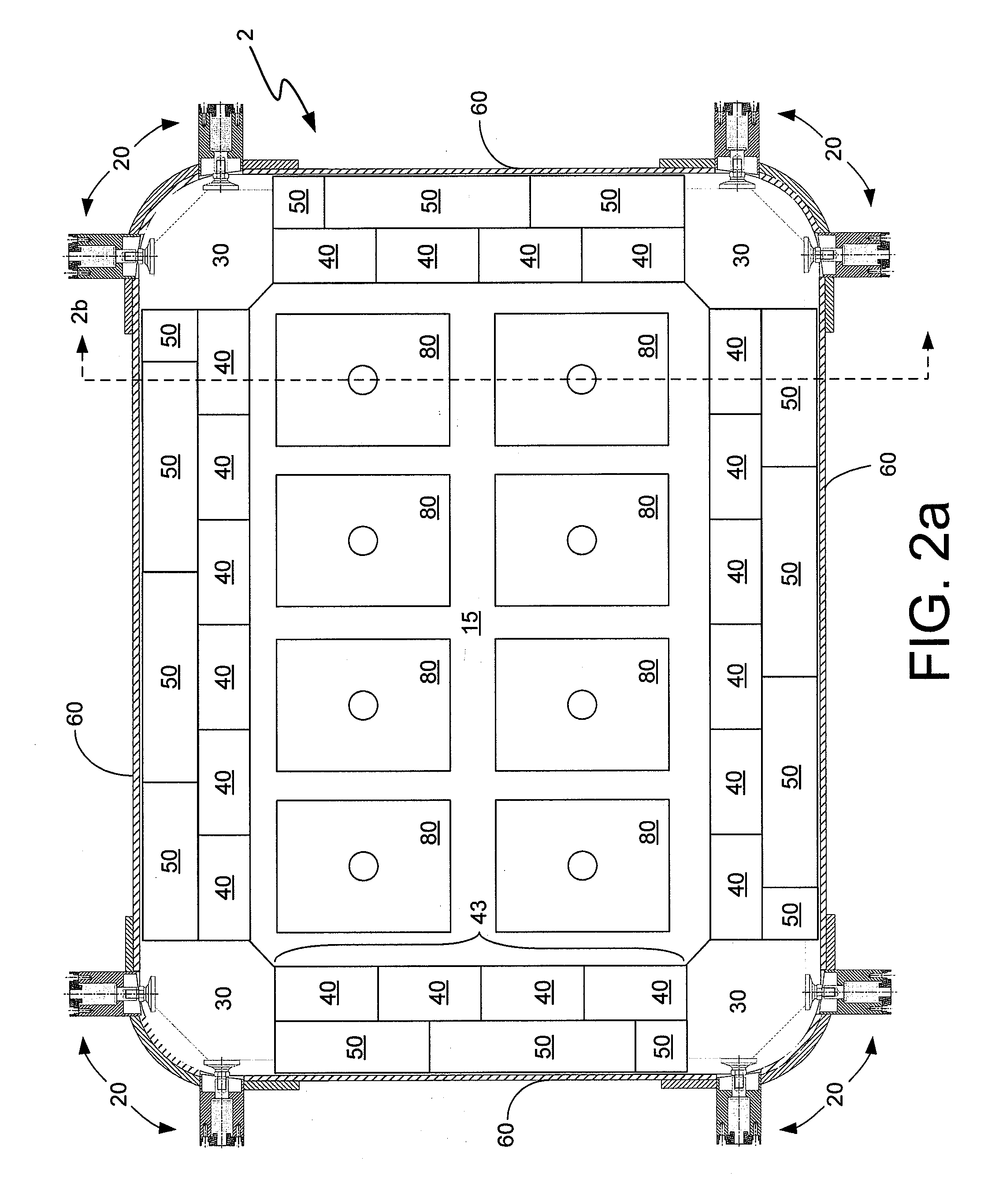

[0020]Reference is now made to the accompanying drawings, which at least assist in illustrating various pertinent features of the instant disclosure.

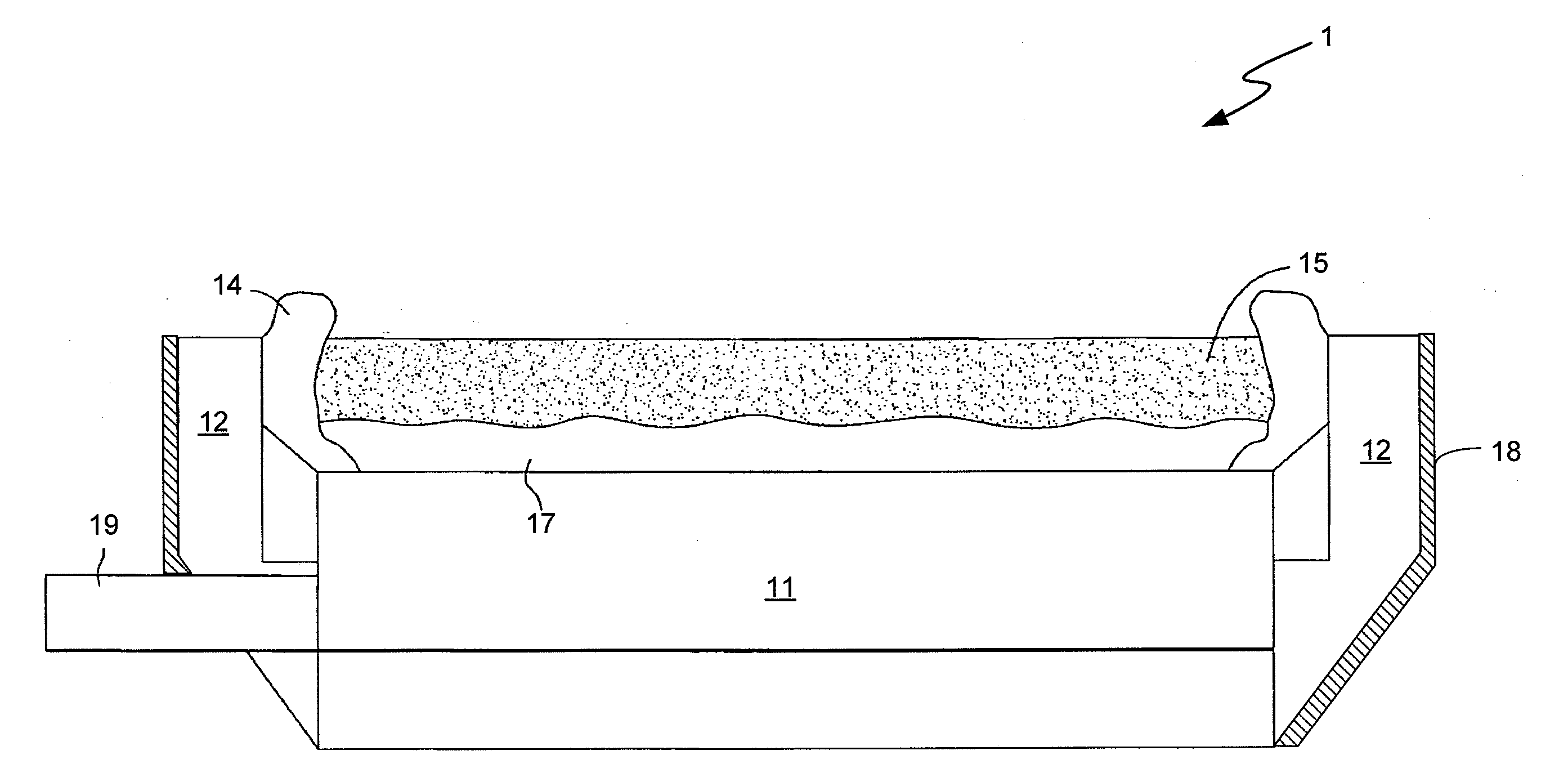

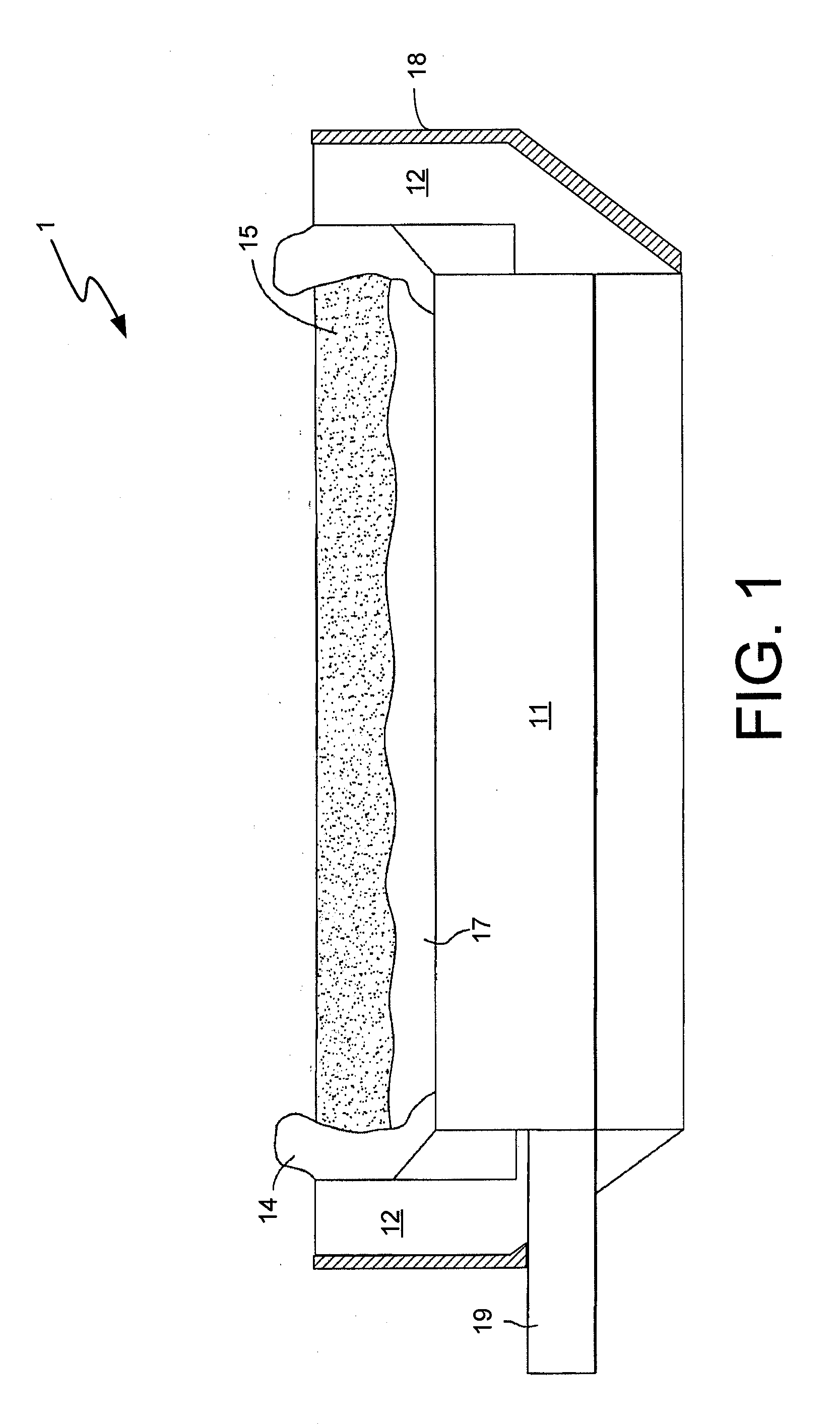

[0021]As noted above, the instant disclosure relates to systems and methods for containing an electrolytic bath in an aluminum electrolysis cell in the absence of a ledge. Conventional aluminum electrolysis cells generally include anodes, a cathode and a plurality of blocks. The arrangement of the plurality of blocks defines a sidewall. During conventional aluminum production processes, a crust generally develops over the electrolytic bath. Crust that develops on the sidewall is often referred to as a ledge. The ledge may protect the sidewall and may prevent the electrolytic bath from leaking out of the cell via cracks between the blocks.

[0022]One embodiment of a conventional aluminum electrolysis cell is illustrated in FIG. 1. In the illustrated embodiment, the cell 1 includes an outer shell 18 containing a conventional sidewall 12. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com