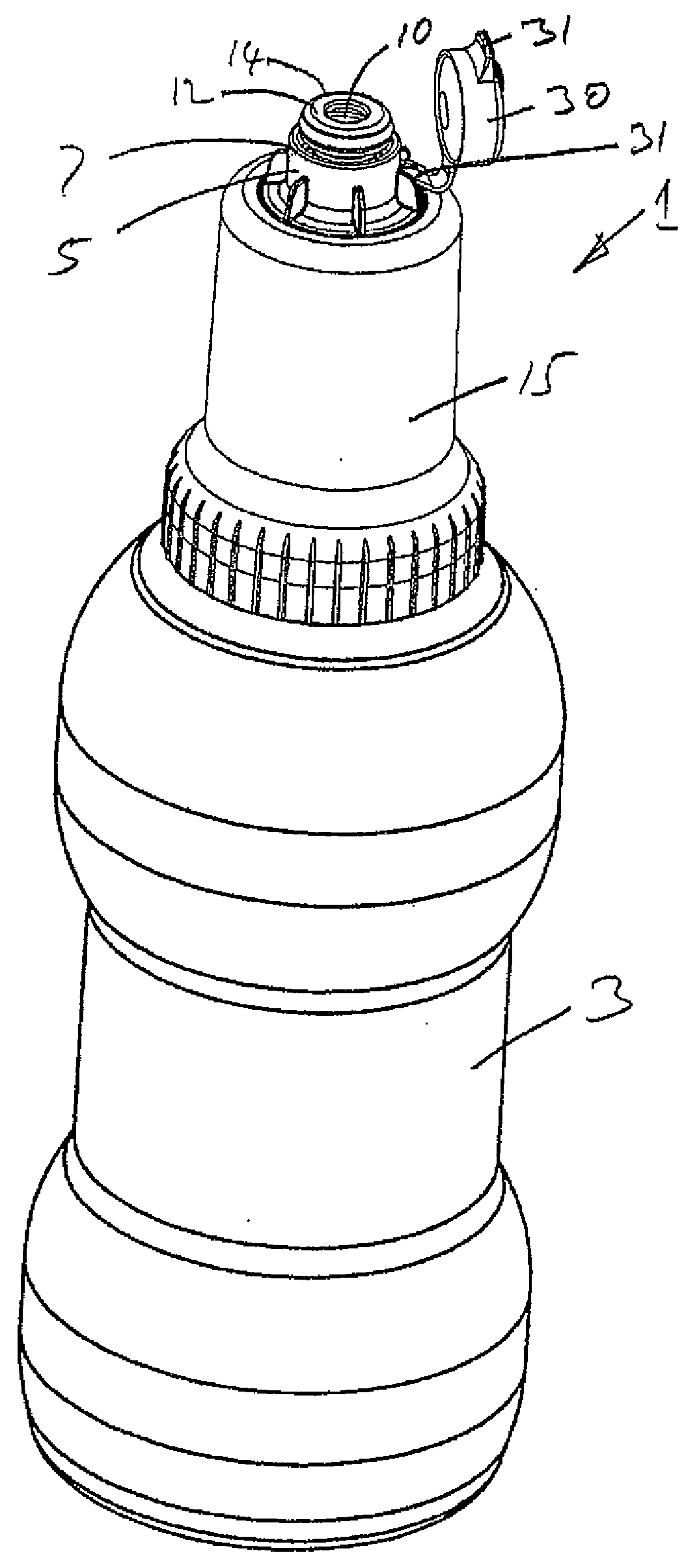

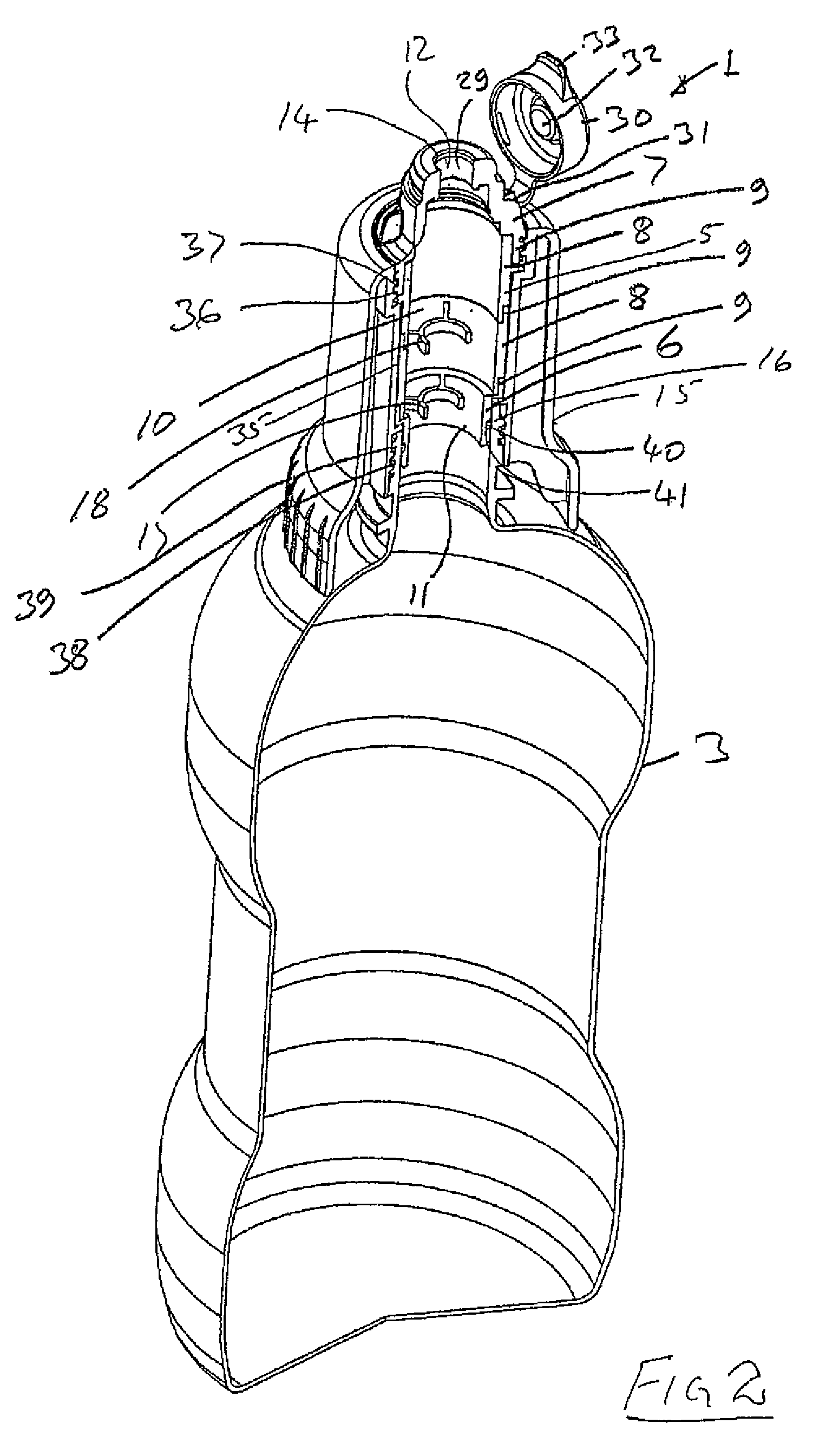

Filter device for filtering liquid from a source

a filter device and liquid filter technology, applied in water/sewage treatment, filtration separation, specific water treatment objectives, etc., can solve the problems of high cost of bottled water, serious illness, and high cost of water purchas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0159]A ceramic filter was prepared from the ingredients listed in Table 1, and prepared according to the steps in Table 2:

TABLE 1Weight % (based onIngredientsceramic filter)Water68.6Copper sulphate0.2pentahydrateBlanose12.6Boron frit23.8Cellulose4.3Diatomaceous earth320.6Total100.01sodium carboxymethylcellulose;27.5% Al2O3, 18.0% B2O3, 50.0% SiO2, 14.0% CaO + MgO, 10.3% Li2O + Na2O + K2O, available from Johnson Mathey Ceramics, Stoke-on-Trent, United Kingdom;350:50 mixture of diatomaceous earths sold under the trade names Celatom FW-14 and FW-80.

TABLE 2Step1Use 400 g of water (at 30° C., ±10)2Add 1 g copper sulphate pentahydrate3Blend in copper for 20 seconds4Add 15 g Blanose, food grade5Blend mixture for 60 seconds6Add 22 g boron frit7Blend mixture for 30 seconds8Add 25 g cellulose9Blend mixture for 100 to 140 seconds10Add 120 g diatomaceous earth11Blend mixture for 180 seconds12Pour onto plaster bat (slab) to form thecomposition13Leave mixture until suitable for shaping(>2 hours)...

example 2

[0160]A precursor filter produced obtained in step 16 of Table 2 in Example 1 was analysed and the results are shown in Table 3:

TABLE 3Weight % (based onIngredientsthe precursor filter)Copper sulphate 0.5%Blanose1 8.2%Borax frit212.0%Cellulose13.7%Diatomaceous earth365.6%Total 100%1sodium carboxymethylcellulose; 27.5% Al2O3, 18.0% B2O3, 50.0% SiO2, 14.0% CaO + MgO, 10.3% Li2O + Na2O + K2O, available from Johnson Mathey Ceramics, Stoke-on-Trent, United Kingdom;350:50 mixture of diatomaceous earths sold under the trade names Celatom FW-14 and FW-80.

example 3

[0161]A ceramic filter of the invention obtained in step 20 of Table 2 of Example 1 was analysed and the content shown in Table 4:

TABLE 4Weight % (based onIngredientsthe ceramic filter)Elemental Copper0.18Diatomaceous earth283.9250:50 mixture of diatomaceous earths sold under the trade names Celatom FW-14 and FW-80.The ceramic filter also comprises frit and other components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com