Exhaust gas control apparatus

a technology of exhaust gas and control apparatus, which is applied in the direction of mechanical apparatus, engine components, machines/engines, etc., can solve the problems of significant loss of exhaust gas energy and loss of part of exhaust gas energy, and achieve the effect of simple, reliable and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

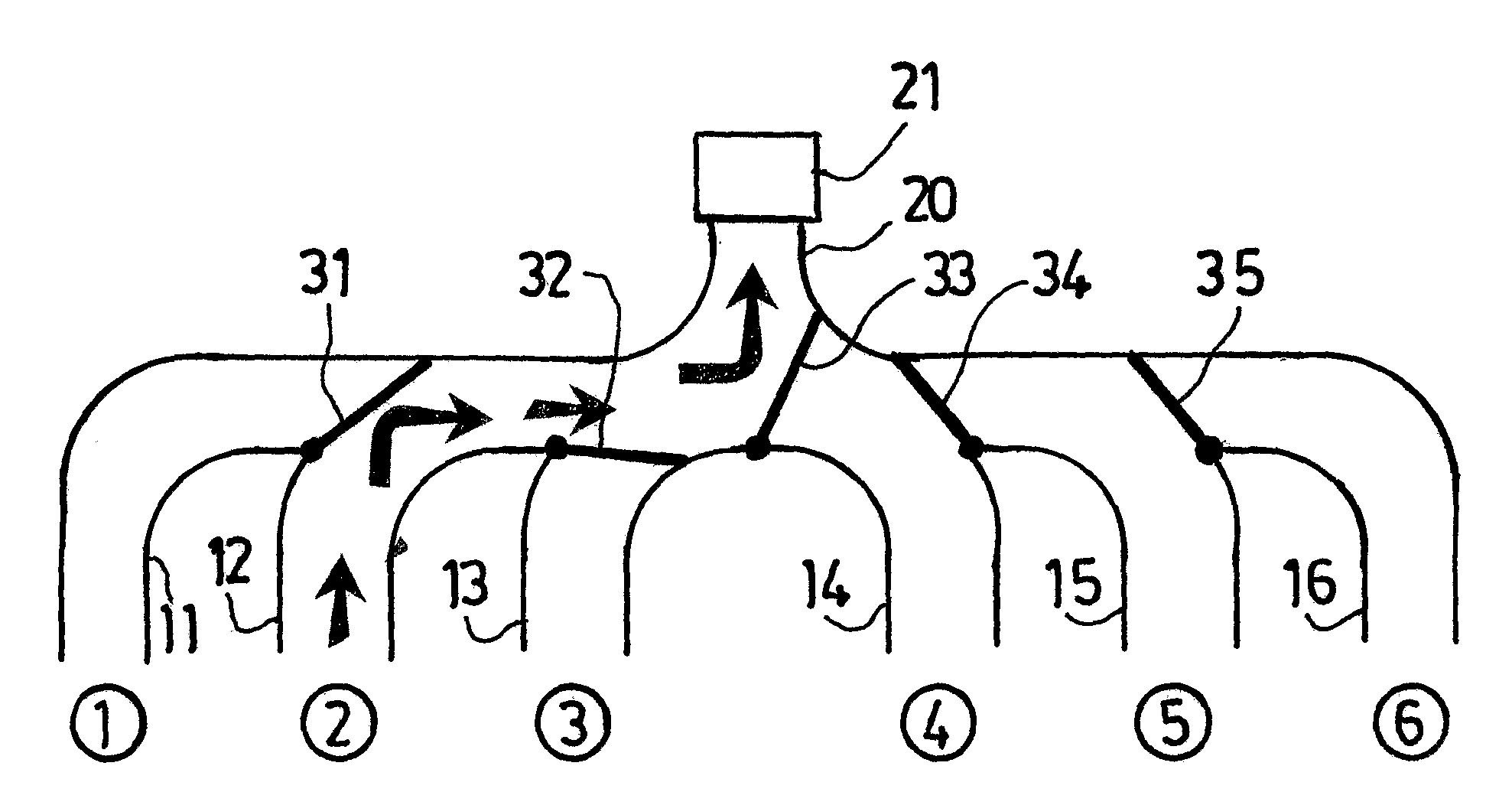

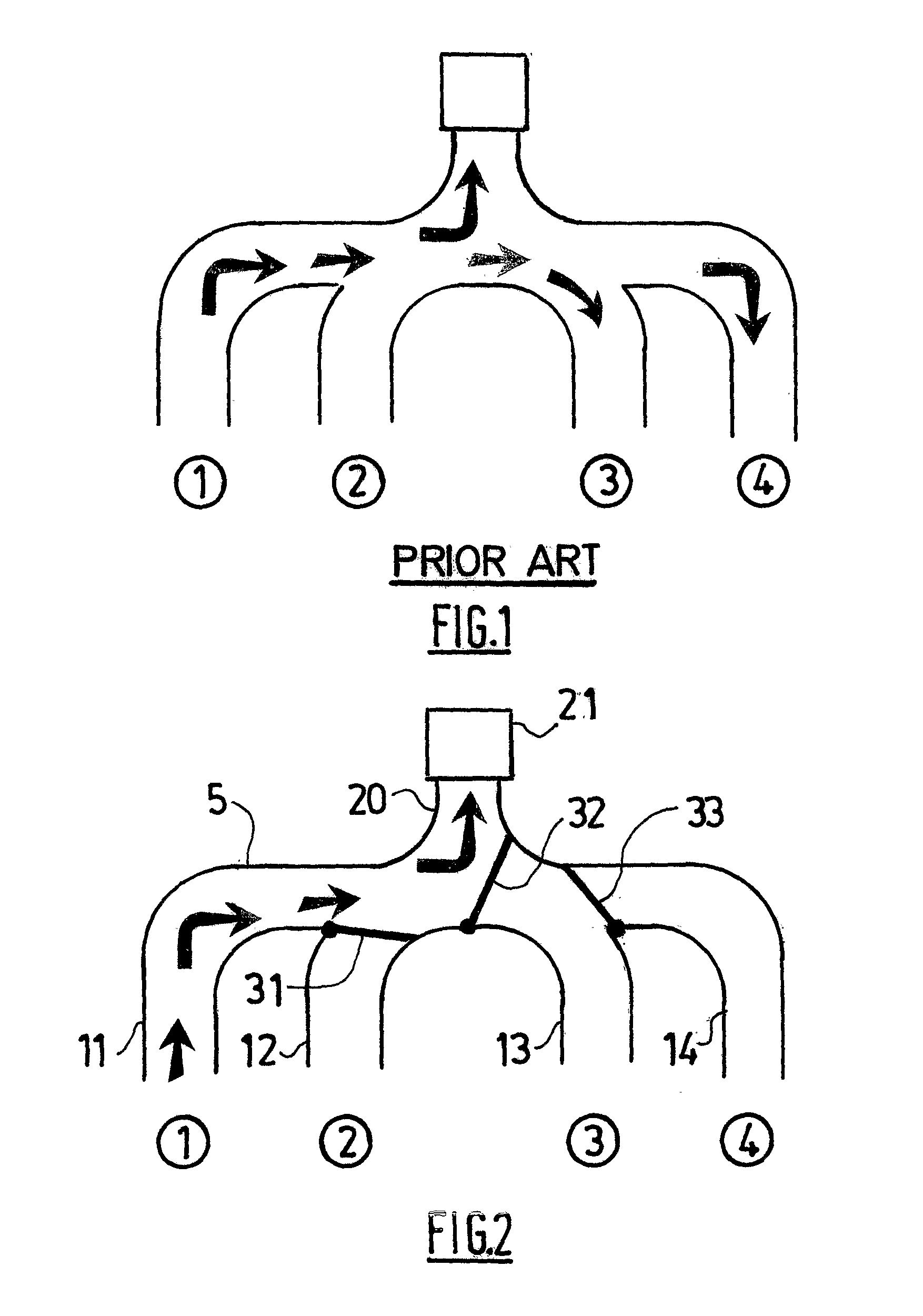

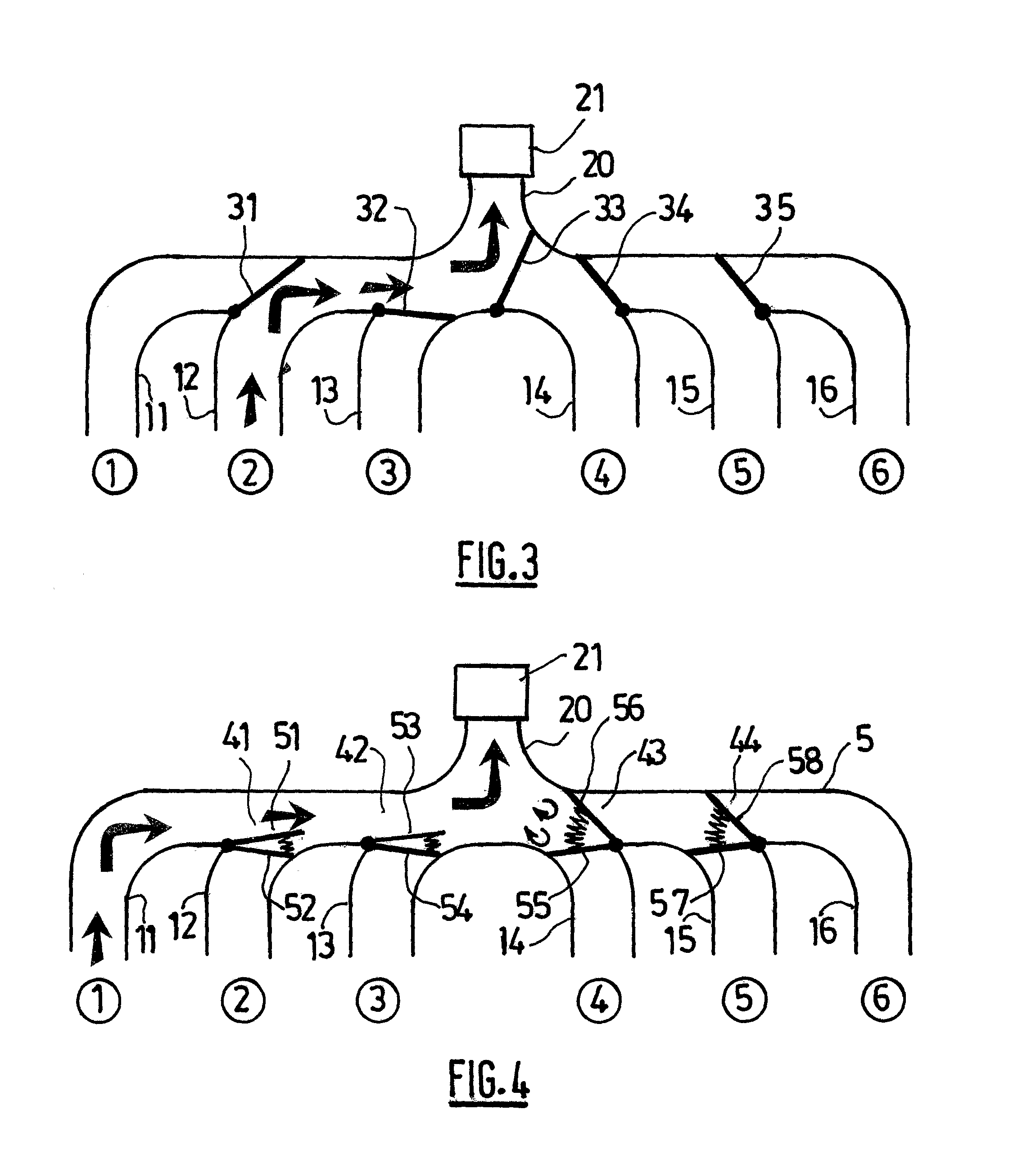

[0028]The exhaust gases control apparatus of the present invention is shown in FIGS. 2 to 6.

[0029]FIG. 2 shows an exhaust manifold 5 for a four cylinder combustion engine equipped with a first embodiment of the apparatus. The exhaust manifold 5 includes four inlet ports 11, 12, 13, 14. Each of the inlet ports 11, 12, 13, 14 is connected to one or more exhaust valves disposed in an engine cylinder head; the exhaust valve(s) release(s) the exhaust gas during the engine exhaust stroke. Neither the engine nor the exhaust valve is further described as they are not part of the present invention. The cylinders are conventionally numbered from 1 to 4.

[0030]The inlet ports 11, 12, 13, 14 merge into an output port 20 upon which a turbine 21 of a turbocharger is fixed. Although not illustrated, the turbine 21 is mechanically linked to a compressor in a known per se manner.

[0031]As depicted in FIG. 2, three valves 31, 32, 33 are disposed in the exhaust manifold. Each valve is pivotally articula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com