Back-up electric power generator for electronic components attached to automatic firearms

a technology of electronic components and electric power generators, which is applied in the direction of machines/engines, transportation and packaging, lighting and heating apparatus, etc., can solve the problems of iron sights, sight or sighting equipment that cannot operate, rendering it useless

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

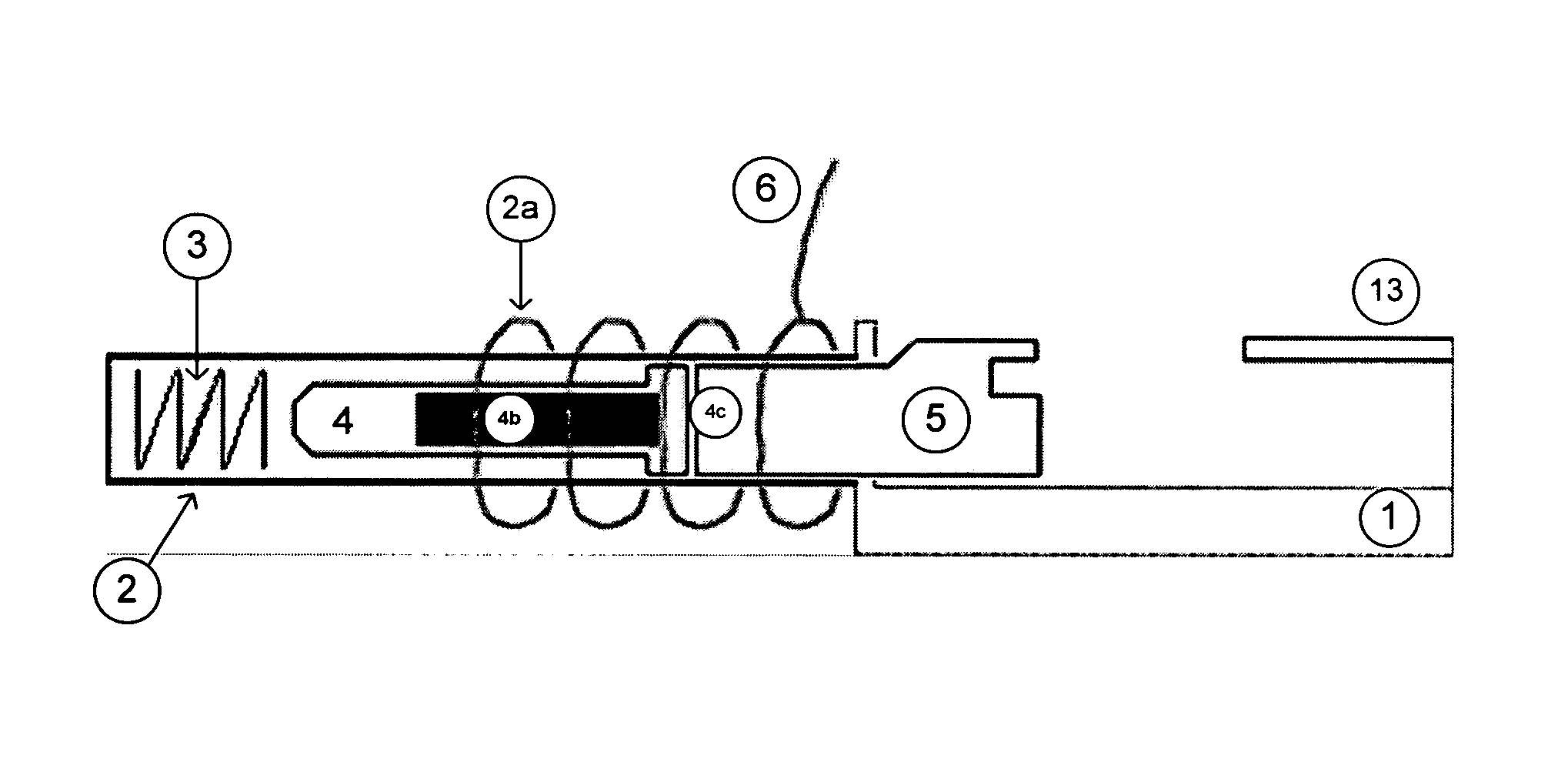

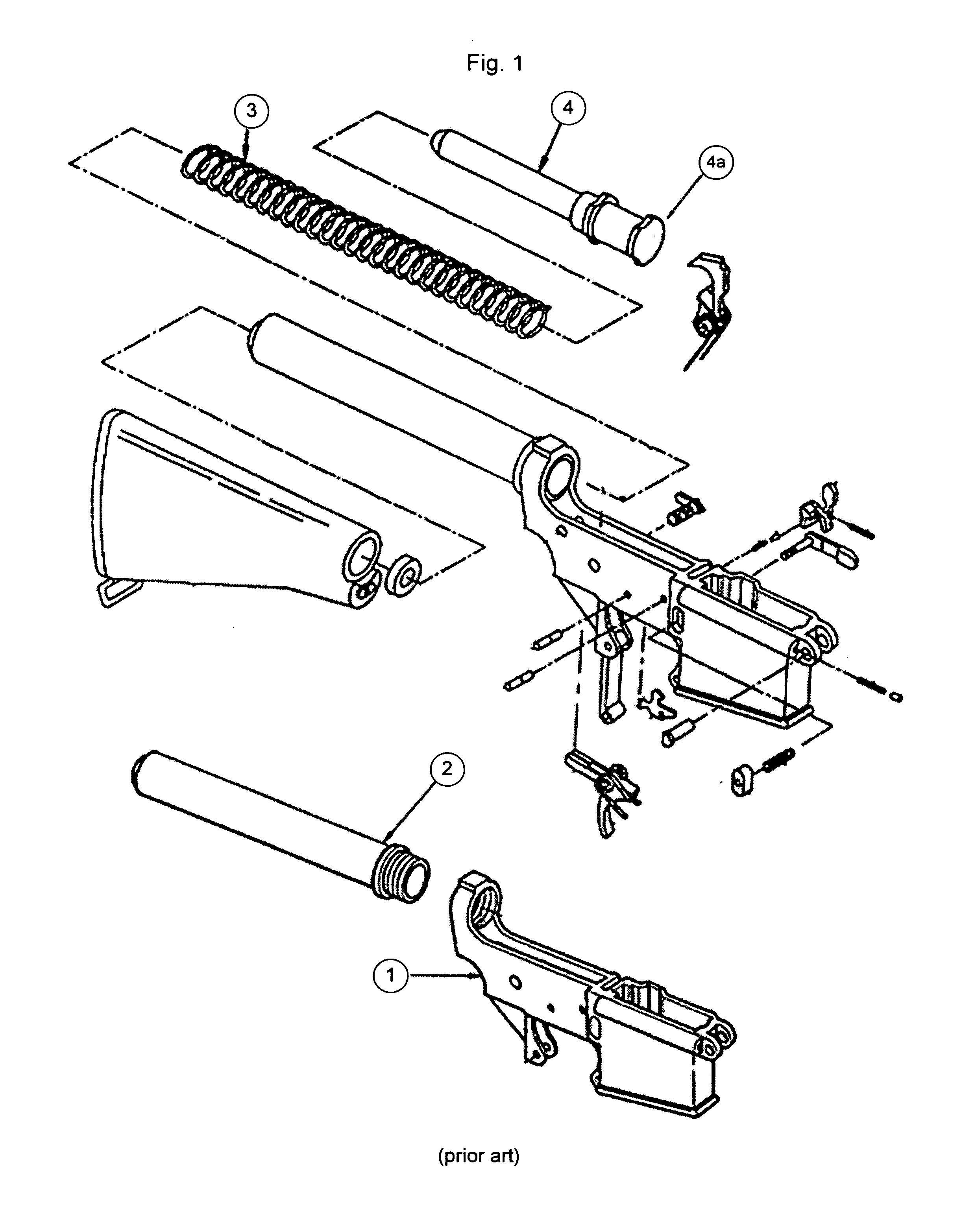

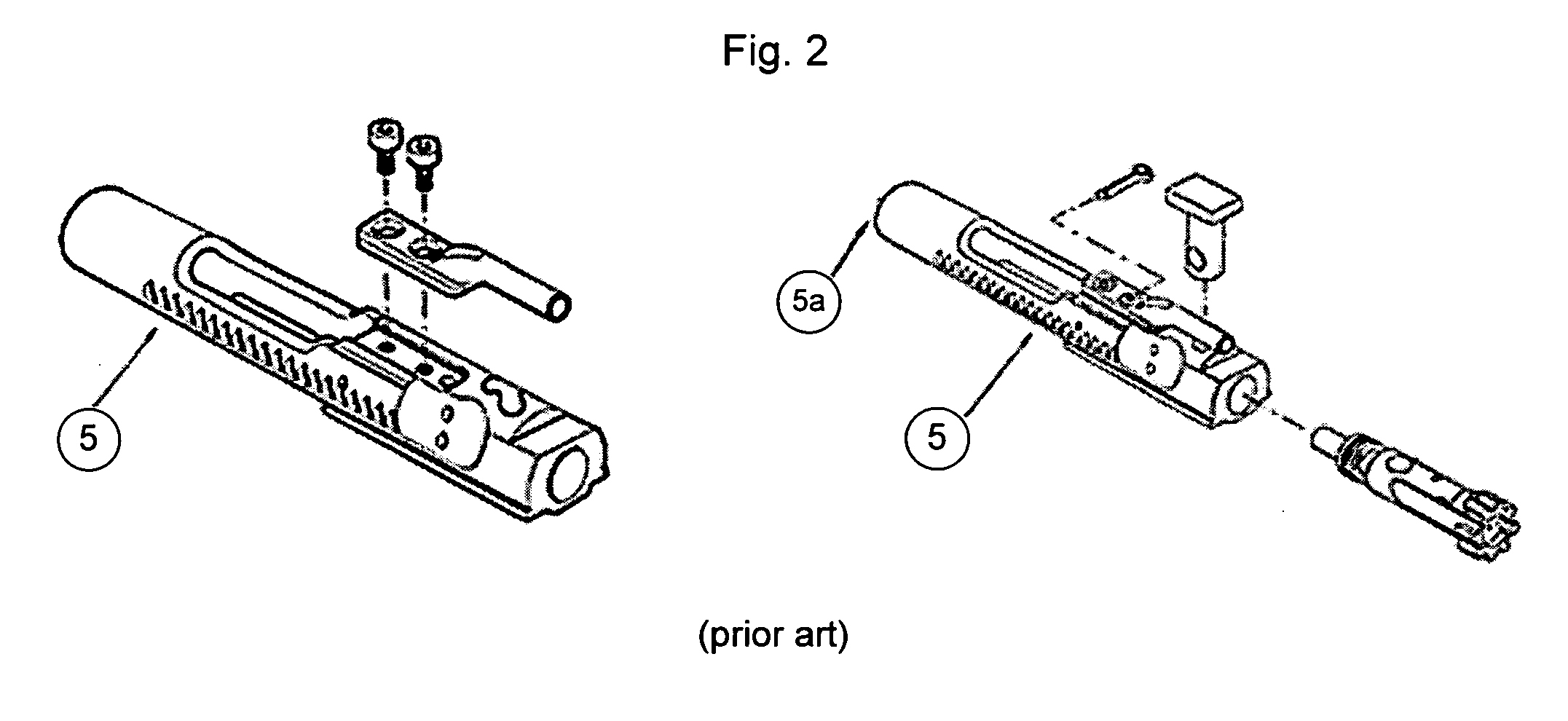

[0028]In one embodiment, the invention is an assembly comprising a group of mechanical components which are either added to an automatic firearm or which are derivatives of existing parts of an automatic firearm and then substituted for the original parts of an automatic firearm. A person skilled in the arts of manufacturing and / or designing mechanical devices may make the invention from modifications to existing rifle parts, by manufacturing rifle parts with the described modifications to certain standards, and by the addition of other pre-manufactured parts to complete the invention.

[0029]Although this application describes the necessary modifications which must be made to an AR-15 rifle to implement the invention, those skilled in the arts of mechanical component manufacture and / or design will be able to make appropriate modifications to other automatic firearms in order to implement the invention on such firearms. As the AR-15 design is widely used by various military units of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com