Method for disposing material by droplet ejection, display device, method for manufacturing display device, and electronic apparatus

a technology of droplet ejection and droplet ejection, which is applied in the manufacture of electric discharge tubes/lamps, identification means, instruments, etc., can solve the problems of reducing production efficiency, reducing the yield of products, and difficulty in precisely controlling the droplet amount, so as to reduce the effect of reducing the width of the shade portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

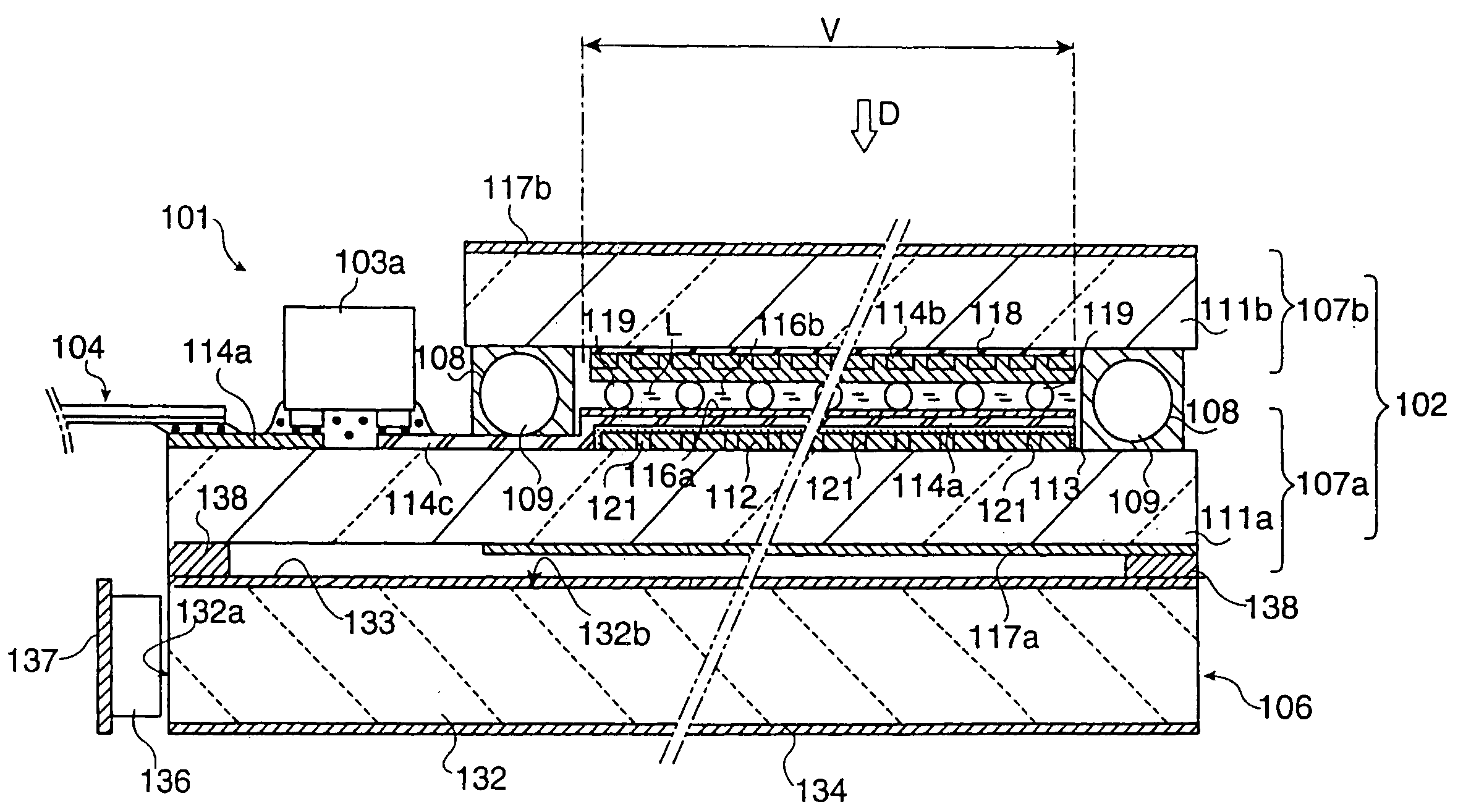

[0152]Next, referring to accompanying drawings, a method for disposing a material by droplet ejection, a display device, a method for manufacturing the display device, and an embodiment of an electronic apparatus will be described in detail. Before the characteristic structure and method of the present invention are described, the structure of a color filter substrate and a manufacturing method therefor, and the structure of an EL panel and a manufacturing method therefor will first be described.

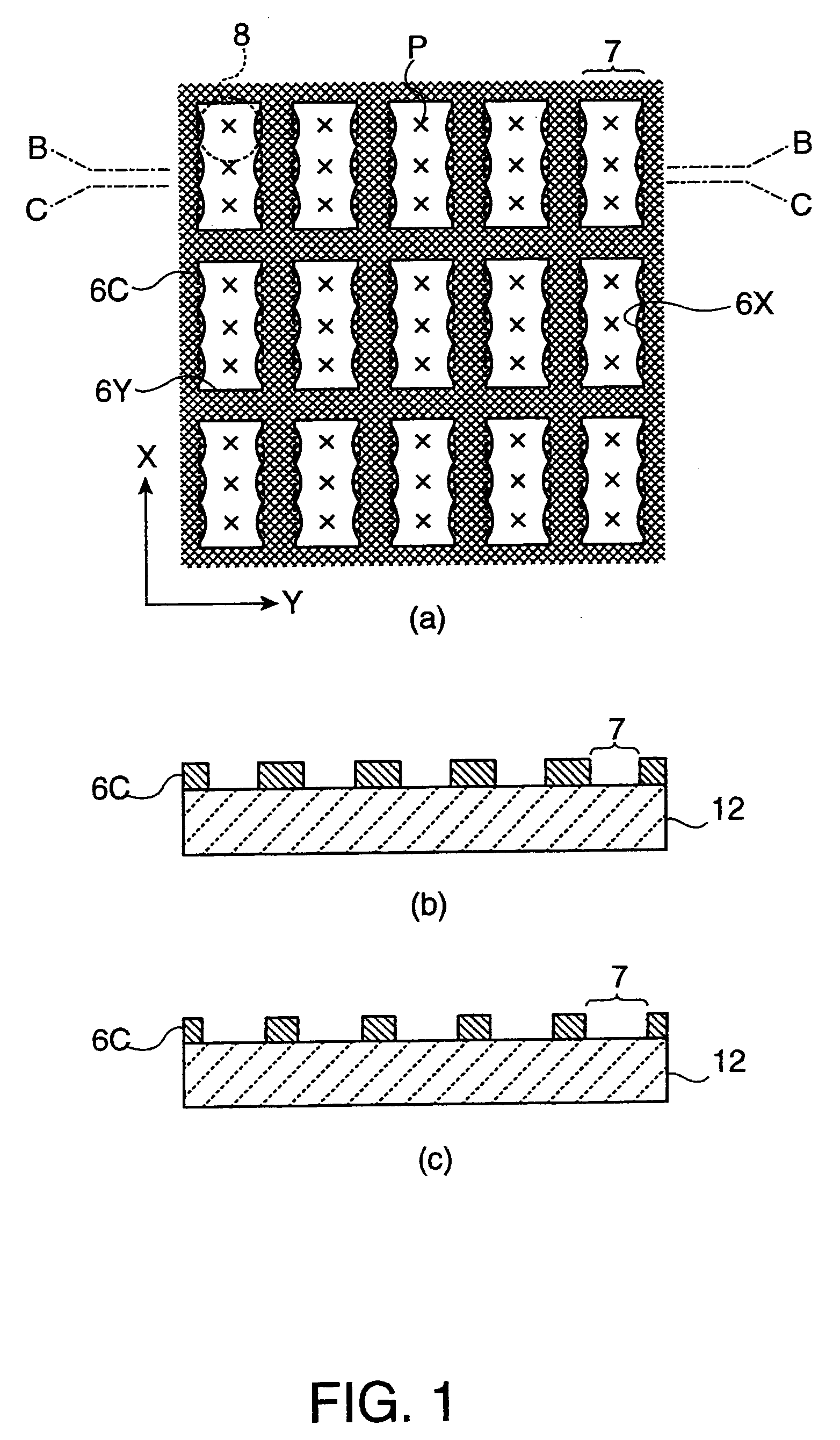

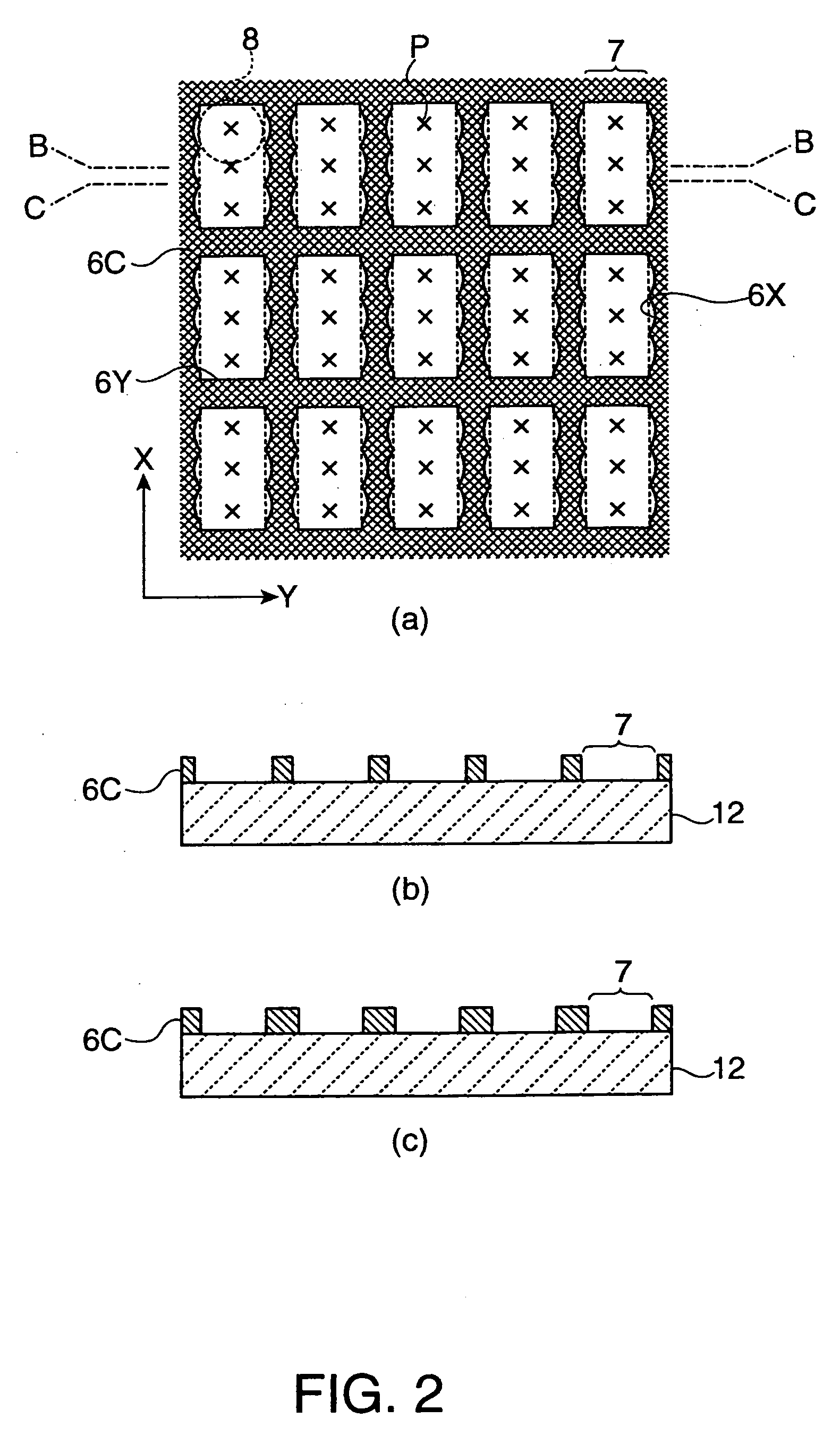

[0153]FIG. 5 shows cross-sectional views for illustrating steps (a) to (g) of a process for manufacturing a color filter substrate, and FIG. 6 is a brief flow chart showing a procedure of the process for manufacturing the color filter substrate.

[0154]First, as shown in FIG. 5(a), to a surface of a substrate 12 having light transparency formed of glass, plastic, or the like, a radiation-sensitive material 6A is applied by one of various methods, such as spin coating (rotation coating), flow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com