Axial compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 150

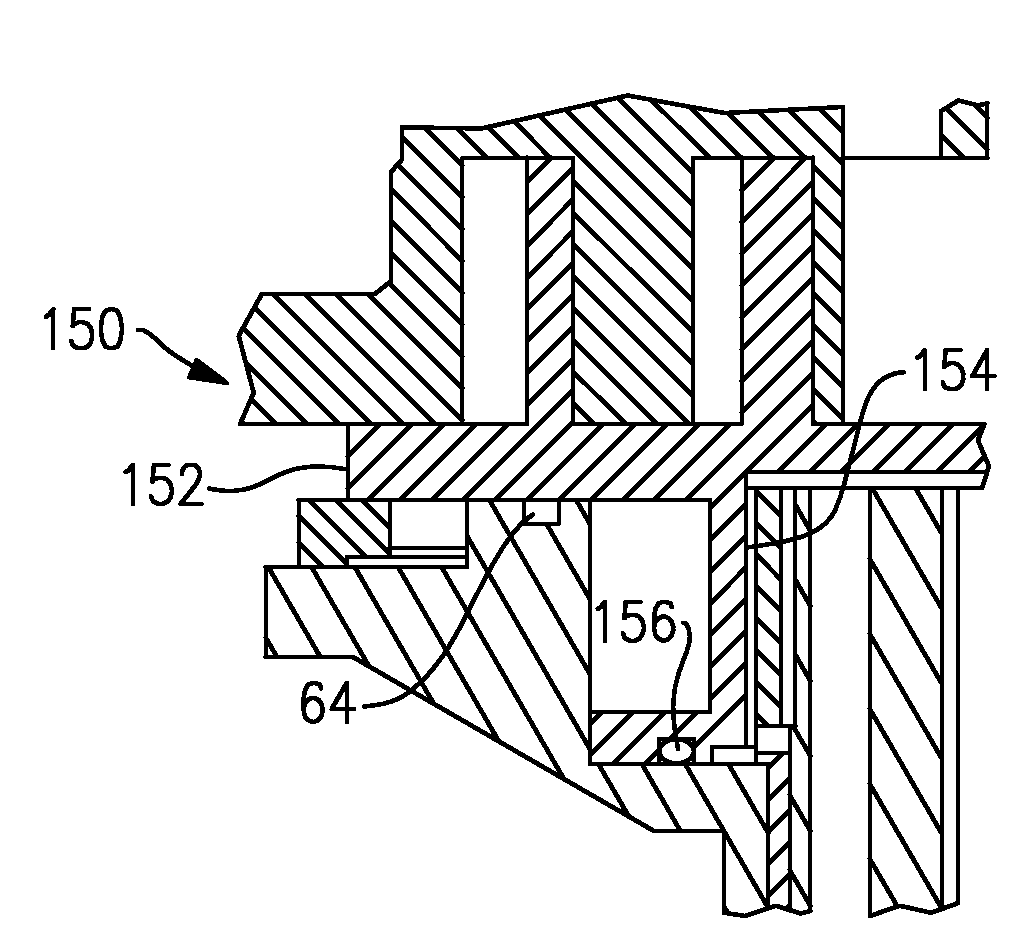

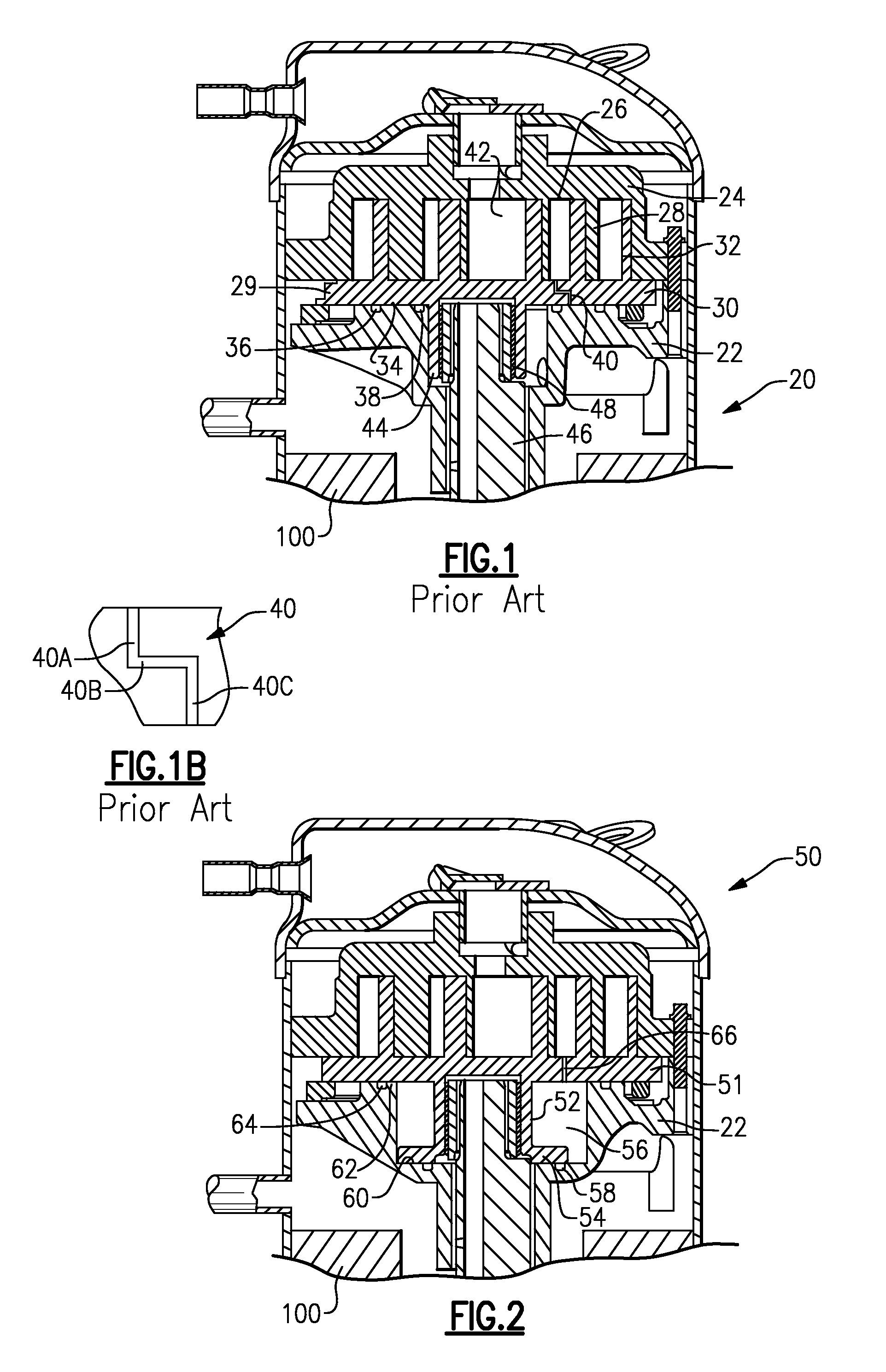

[0021]An embodiment 150 is shown in FIG. 3, wherein the radially inner seal 156 is in the hub 154 of the orbiting scroll 152. The radially outer seal 64 remains in the crankcase. Of course, the two seal locations could be reversed, with the radially outer seal in the orbiting scroll and the radially inner seal in the crankcase.

embodiment 250

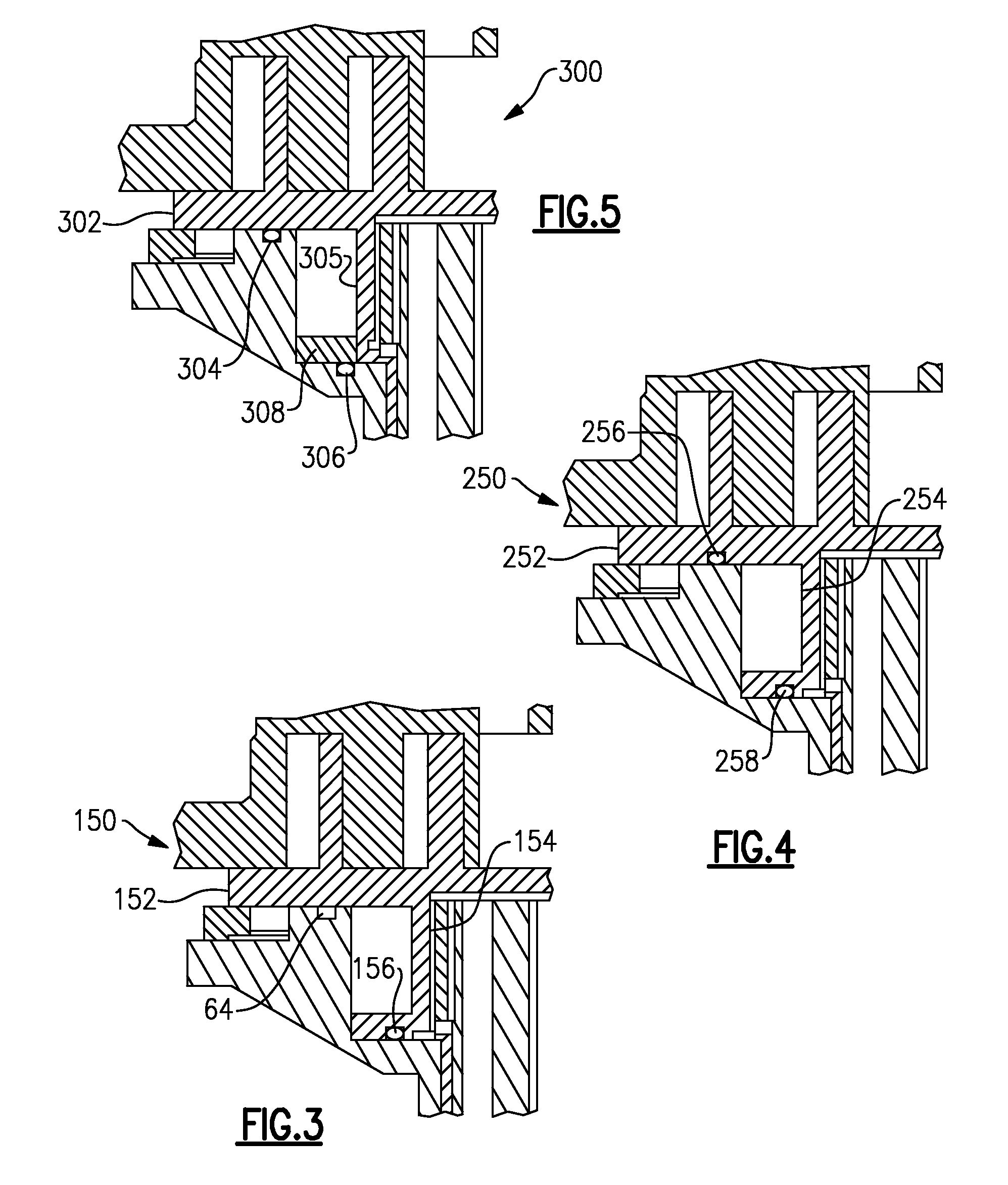

[0022]FIG. 4 shows another embodiment 250 wherein the orbiting scroll 252 has the hub 254 receiving the radially inner seal 258. The base of the orbiting scroll 252 receives the radially outer seal 256.

embodiment 300

[0023]FIG. 5 shows another embodiment 300 wherein the orbiting scroll 302 includes a hub 305 with a separate member 308 that contacts the radially inner seal 306. The radially outer seal 304 sits in the crankcase in this embodiment. In this embodiment, the formation of the orbiting scroll is simplified in that the hub need not have the radially outwardly extending lowermost portion, but can instead receive a separate component to provide that function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com