Impeller

a technology of impeller and blade, which is applied in the direction of liquid fuel engine, machine/engine, reaction engine, etc., can solve the problems of poor mass uniformity of the parts of the impeller such as the annular plate or the blade distant from the central axis of the impeller, adversely affecting the effect and stability of the electronic device, etc., to achieve the effect of improving the balancing precision and being easy to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

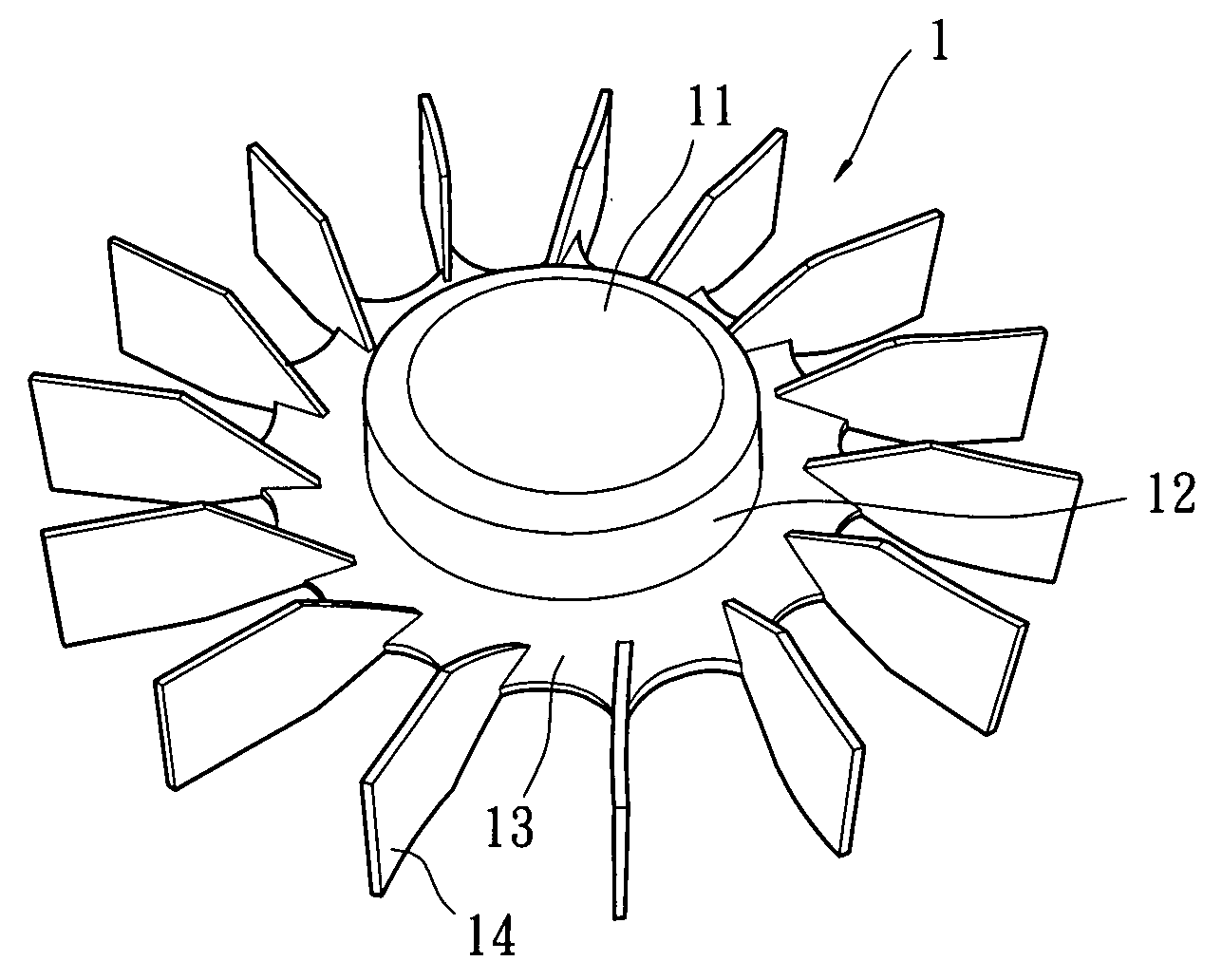

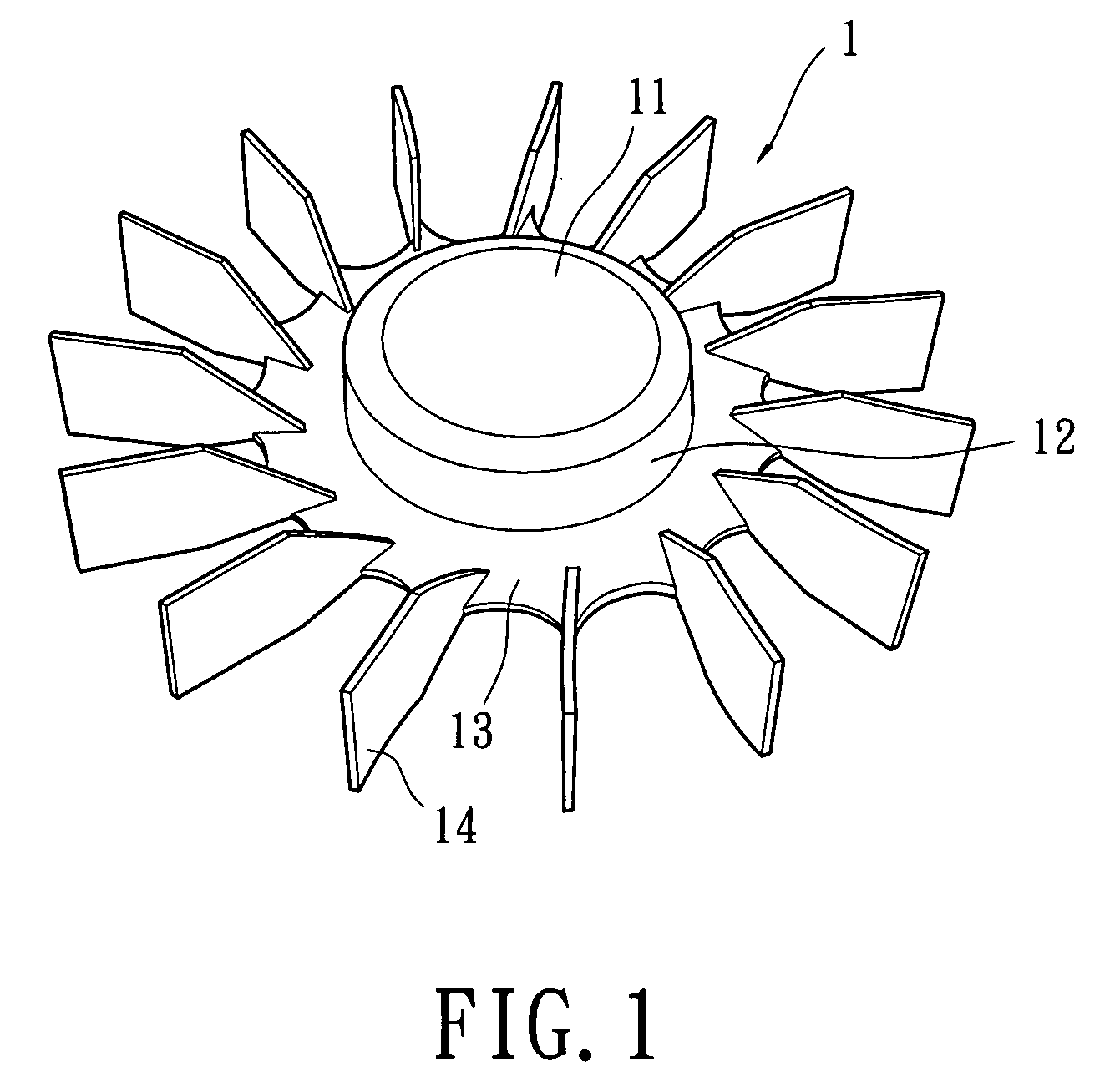

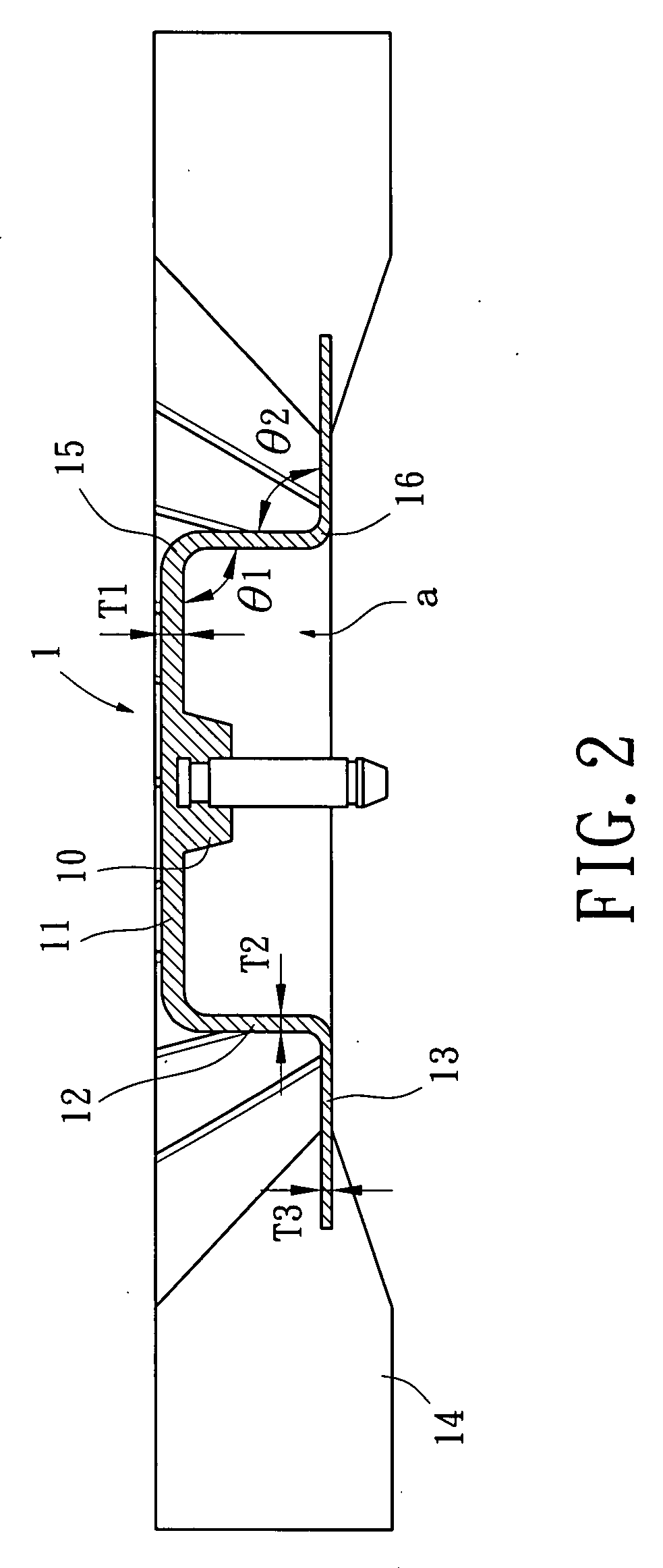

[0017]An impeller 1 of a first embodiment according to the preferred teachings of the present invention is shown in FIGS. 1-2. The impeller 1 includes a shaft base 10 defining a central axis about which the impeller 1 rotates. The impeller 1 further includes a plurality of portions and a plurality of bends. In the first embodiment shown, according to the distance to the shaft base 10, the plurality of portions correspond to a top portion 11 of a hub of the impeller 1 (i.e., the first portion), an annular wall 12 of the hub of the impeller 1 (i.e., the second portion), and an annular plate portion 13 (i.e., the third portion). Specifically, the top portion 11 of the hub extends radially outward from a circumference of the shaft base 10. The annular wall portion 12 of the hub extends from an outer circumference of the top portion 11 of the hub in a direction perpendicular to a general plane on which the top portion 11 lies. The top portion 11 and the annular wall portion 12 together d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com