Method of optimized gradient coil design

a gradient coil and design technology, applied in the field of new gradient coil design method, can solve the problems of worm bore or cold shield of the magnet eddy current induced in the worm bore or the magnetic shield, and is difficult to find a continuous solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

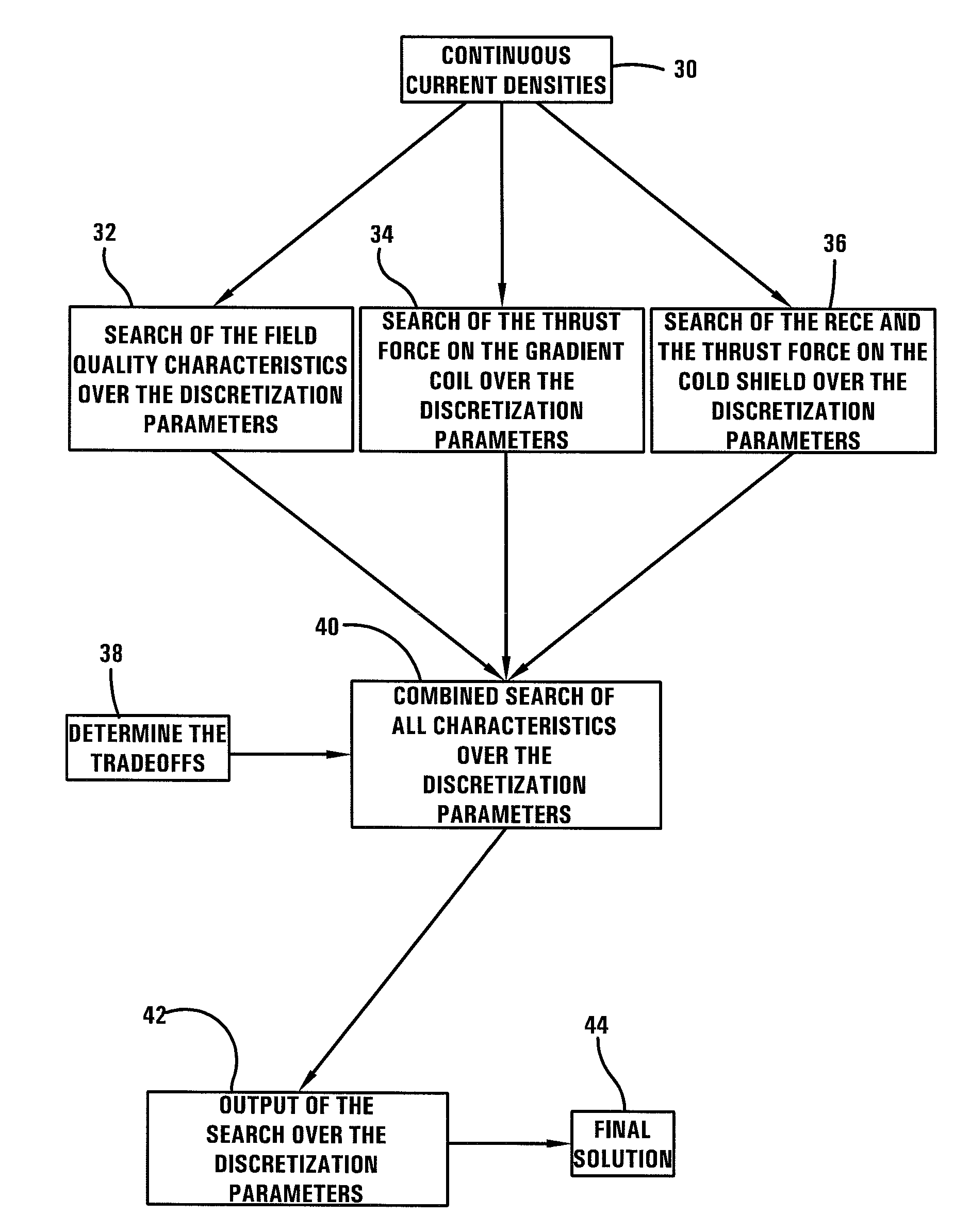

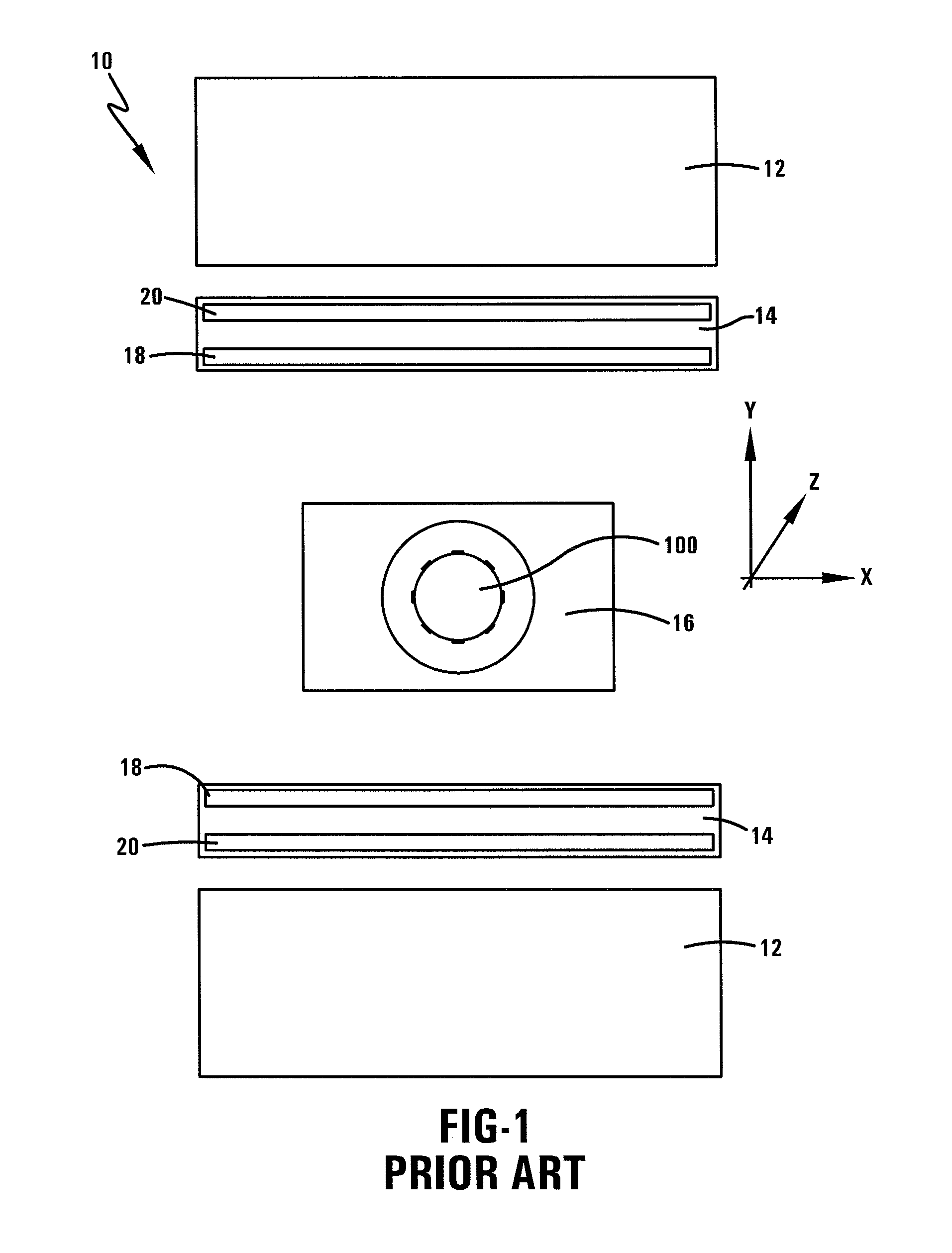

[0045]Referring now to the drawings wherein the showings are for purposes of illustrating numerous embodiments of the invention only and not for purposes of limiting the same, the figures illustrate the novel idea of an improved method of discretization of the continuous current solution of a gradient coil design.

[0046]The present invention puts forth an improved method of gradient coil design using an improved discretization process of the continuous current solution. The present invention applies to the design of both axial and transverse gradient coil design.

[0047]Axial Gradient Coil

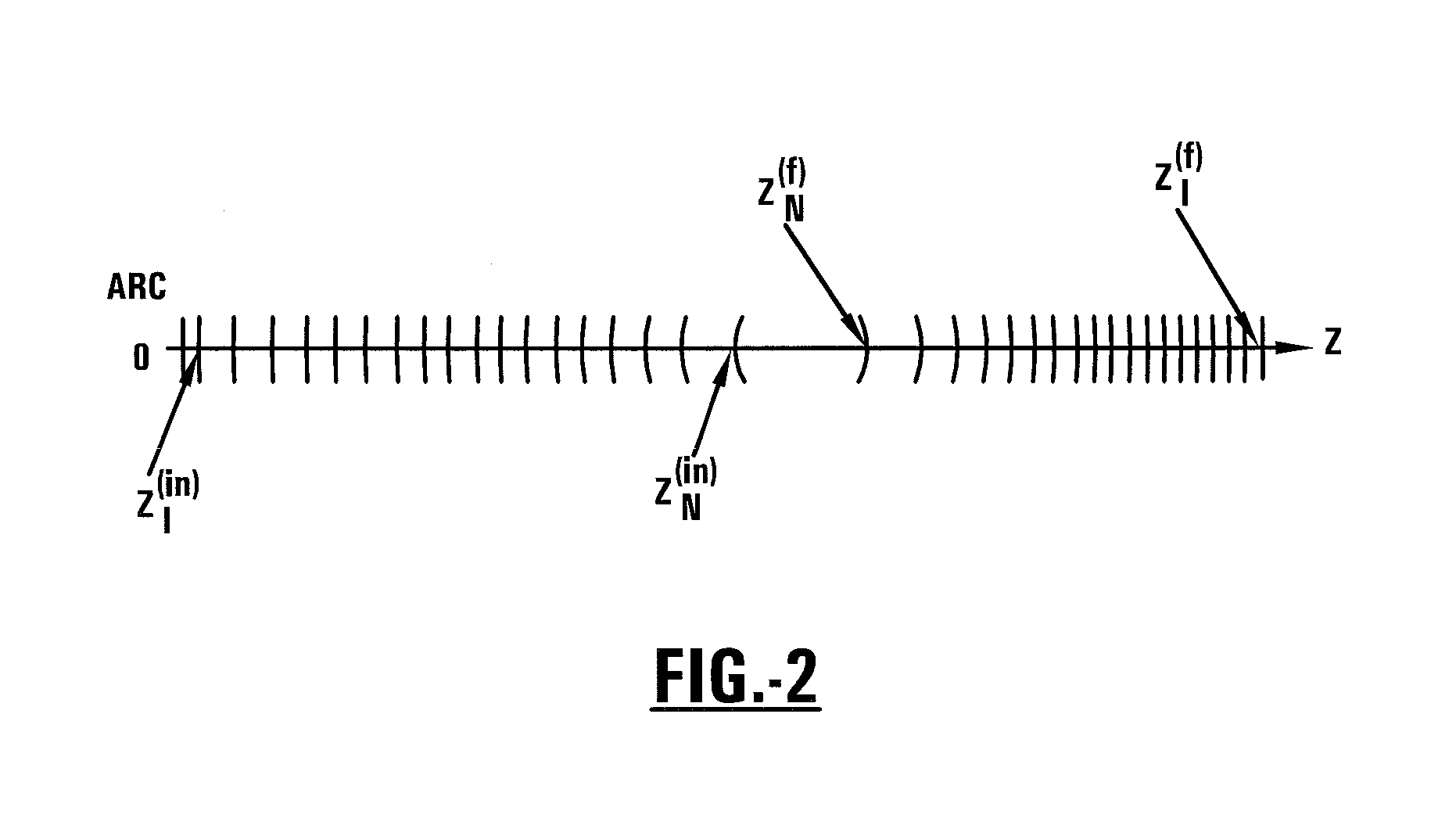

[0048]The method of designing an axial gradient coil of embodiments of the invention, wherein the axial gradient coil having a primary coil and a shield coil for use in magnetic resonance imaging, includes defining at least one performance characteristic of the axial gradient coil, concurrently varying at least two parameters within at least one equation, wherein each result of the varied at least two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com