Nanosized particles of monoazo laked pigment with tunable properties

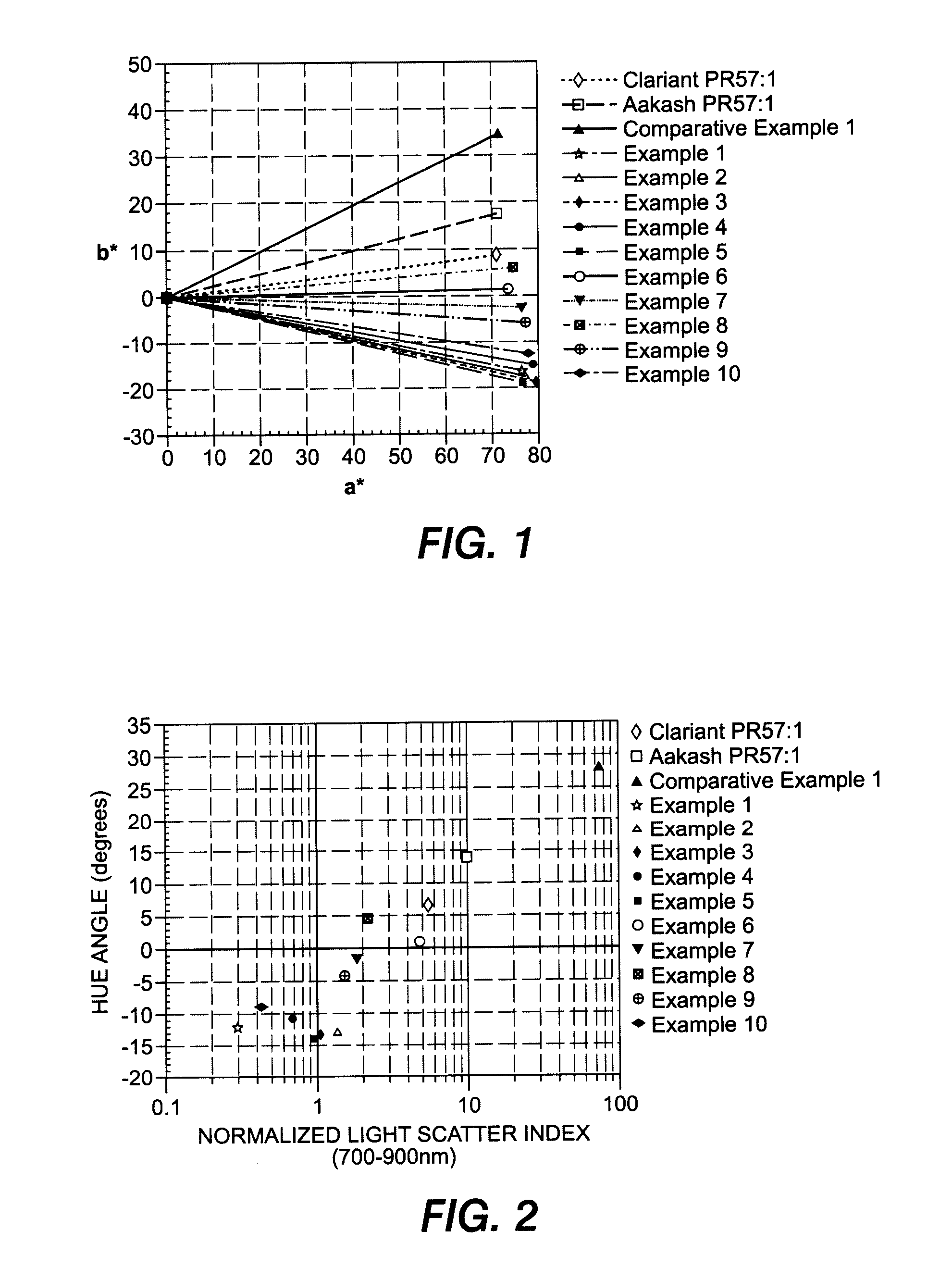

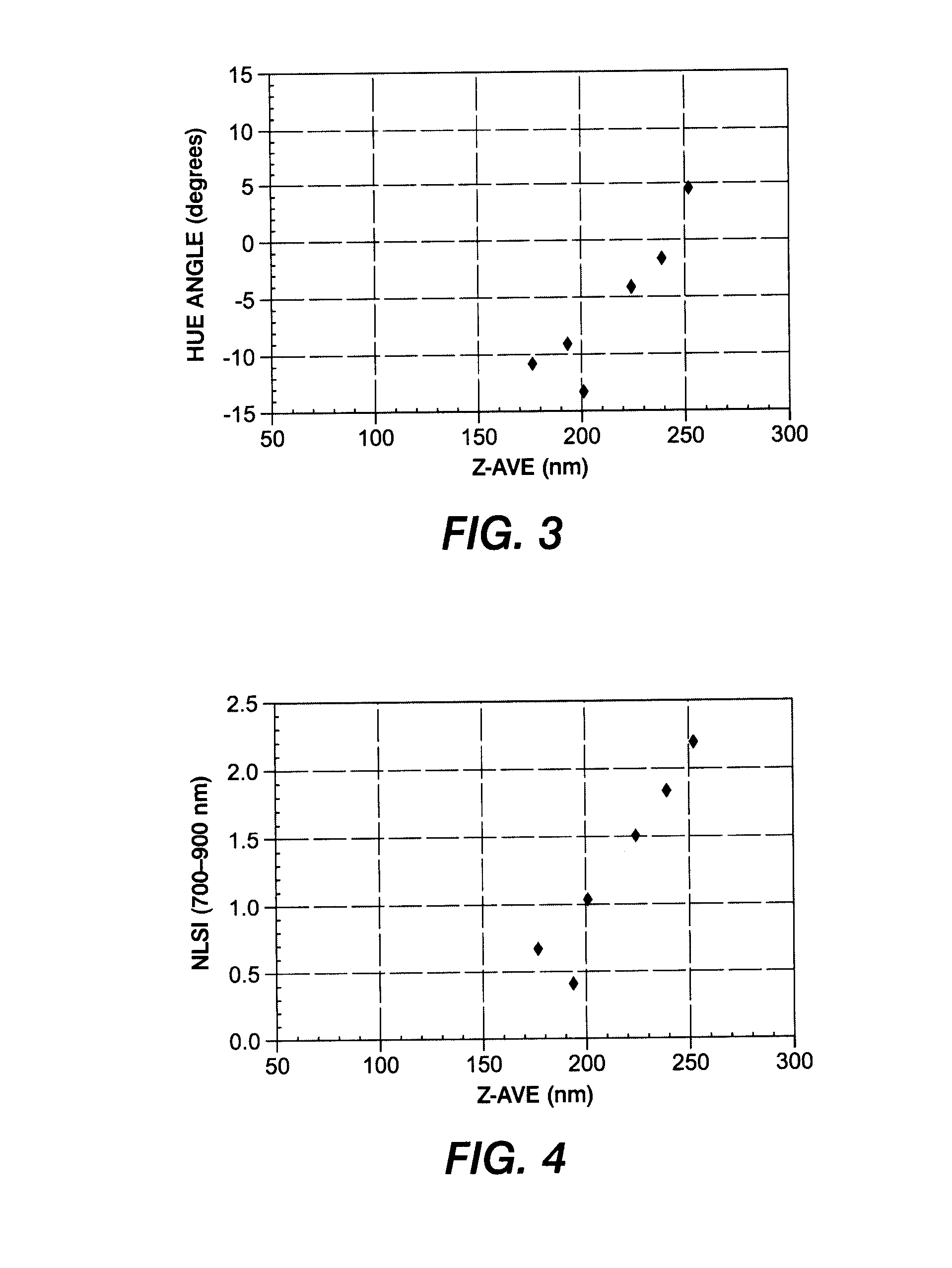

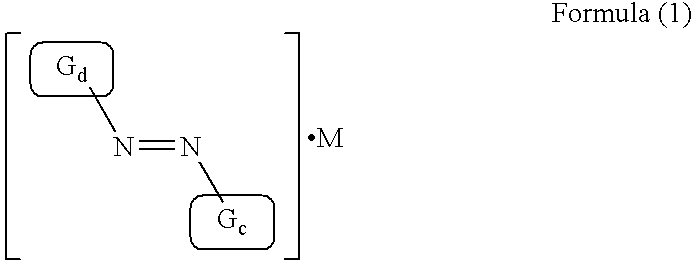

a monoazo laked pigment and nanoscale technology, applied in the field of nanoscale pigment particle compositions, can solve the problems of poor ink performance, poor lightfastness, poor image quality and showthrough,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Nano-Sized Particles of Pigment Red 57:1 by a Two-Step Method

[0096]Step 1: Diazotization and Coupling: Into a 500 mL round bottom flask equipped with a mechanical stirrer, thermometer, and addition funnel was dissolved 2-amino-5-methylbenzenesulfonic acid (8.82 g) into 0.5M KOH aqueous solution (97.0 mL). The resulting brown solution was cooled to 0° C. A 20 wt % aqueous solution of sodium nitrite (NaNO2; 3.28 g dissolved into 25 mL water) was added slowly to the first solution while maintaining the temperature below 3° C. To the red-brown homogeneous mixture was added dropwise concentrated HCl (10M, 14.15 mL) over 1 hour, maintaining the internal temperature below 2° C. The mixture formed a pale brown suspension, and following complete addition of conc. HCl, the suspension was stirred an additional 30 min.

[0097]In a separate 2-L resin kettle was dissolved 3-hydroxy-2-naphthoic acid (8.86 g) into an aqueous solution of KOH (8.72 g) in water (100 mL). An additional 250 m...

example 2

Synthesis of Nano-Sized Particles of Pigment Red 57:1 by a Two-Step Method

[0100]The procedure of Step 1 of Example 1 above was reproduced.

[0101]Step 2: Laking

[0102]Into a 500 mL round bottom flask equipped with mechanical stirrer and condenser was charged 126 g of aqueous slurry of Lithol Rubine-Potassium salt dye from above (Example 1) having about 1.6% wt solids content. The pH of the slurry was adjusted to at least 9.0 or higher by addition of 0.5 M KOH solution, after which the dyestuff was fully dissolved. An aqueous solution 5 wt % Dresinate X (4.0 mL) was added, followed by a solution containing sodium dioctyl sulfosuccinate (0.96 g) dissolved in 100 mL of 90:10 deionized water / THF mixture. No visible change was observed. An aqueous solution of calcium chloride dihydrate (0.5 M solution, 13 mL) was added dropwise to the slurry while stirring vigorously. A red precipitate formed immediately, and after complete addition of the calcium chloride solution, the slurry was stirred f...

example 3

Synthesis of Nano-Sized Particles of Pigment Red 57:1 by a Two-Step Method

[0103]Step 1: Diazotization and Coupling: Into a 500 mL round bottom flask equipped with a mechanical stirrer, thermometer, and addition funnel was dissolved 2-amino-5-methylbenzenesulfonic acid (12.15 g) into 0.5M KOH aqueous solution (135 mL). The resulting brown solution was cooled to 0° C. A 20 wt % aqueous solution of sodium nitrite (NaNO2; 4.52 g dissolved into 30 mL water) was added slowly to the first solution while maintaining the temperature below −2° C. Concentrated HCl (10M, 19.5 mL) was then slowly added dropwise over 1 hour while maintaining the internal temperature below 0° C. The mixture formed a pale brown suspension and following complete addition of conc. HCl, the suspension was stirred an additional 30 min.

[0104]In a separate 2-L resin kettle was dissolved 3-hydroxy-2-naphthoic acid (12.2 g) into an aqueous solution of KOH (12.0 g) in water (130 mL). An additional 370 mL of water was added,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com