Internal Fixer For Anchor Having Releasable Tensioning Steel Wire

a technology of tensioning steel wire and fixing rod, which is applied in the direction of building reinforcements, construction, building components, etc., can solve the problems of increasing construction period, damage to excavators and boring machines, etc., and achieves the effects of convenient and reliable removal, easy release, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

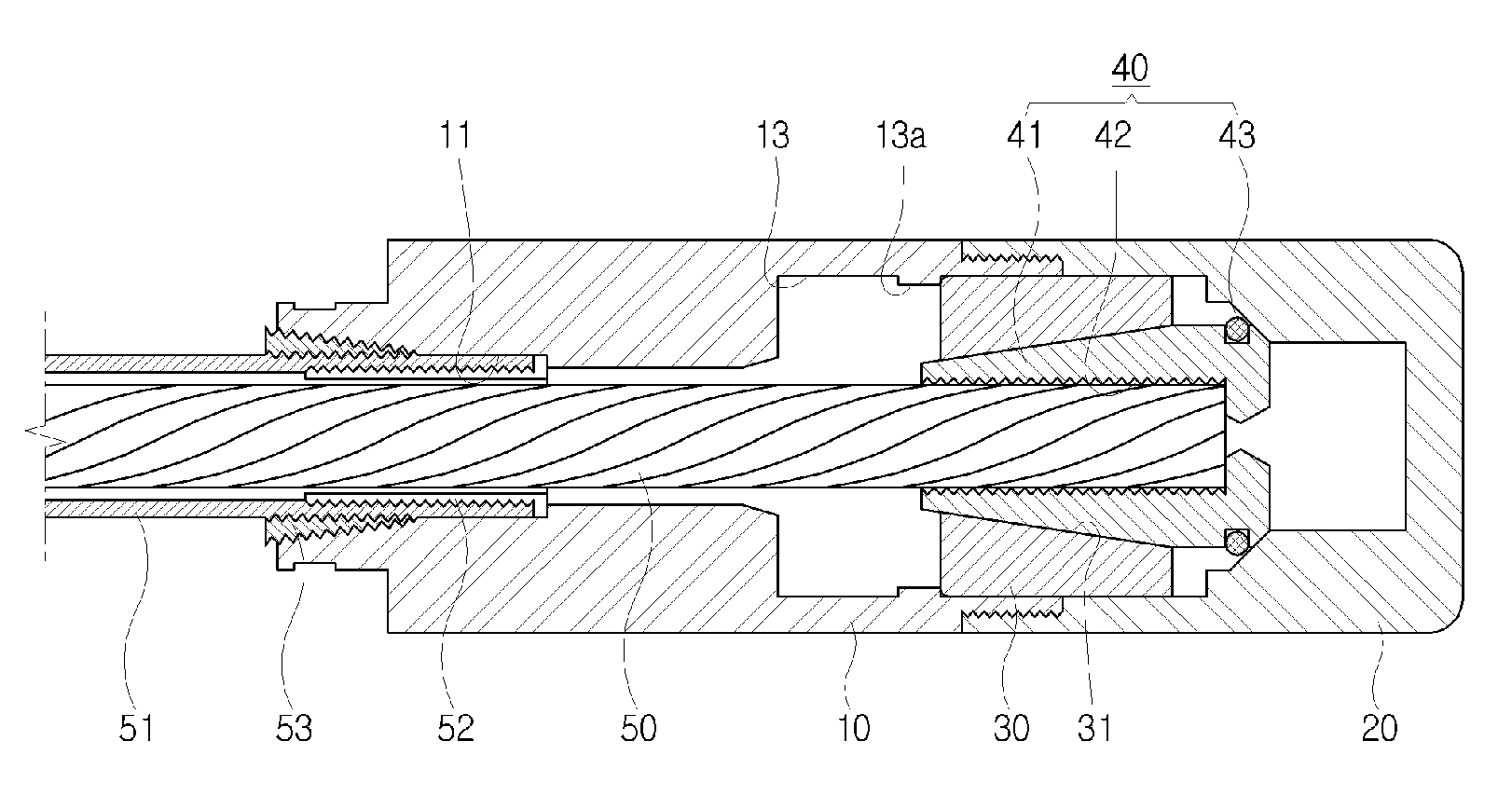

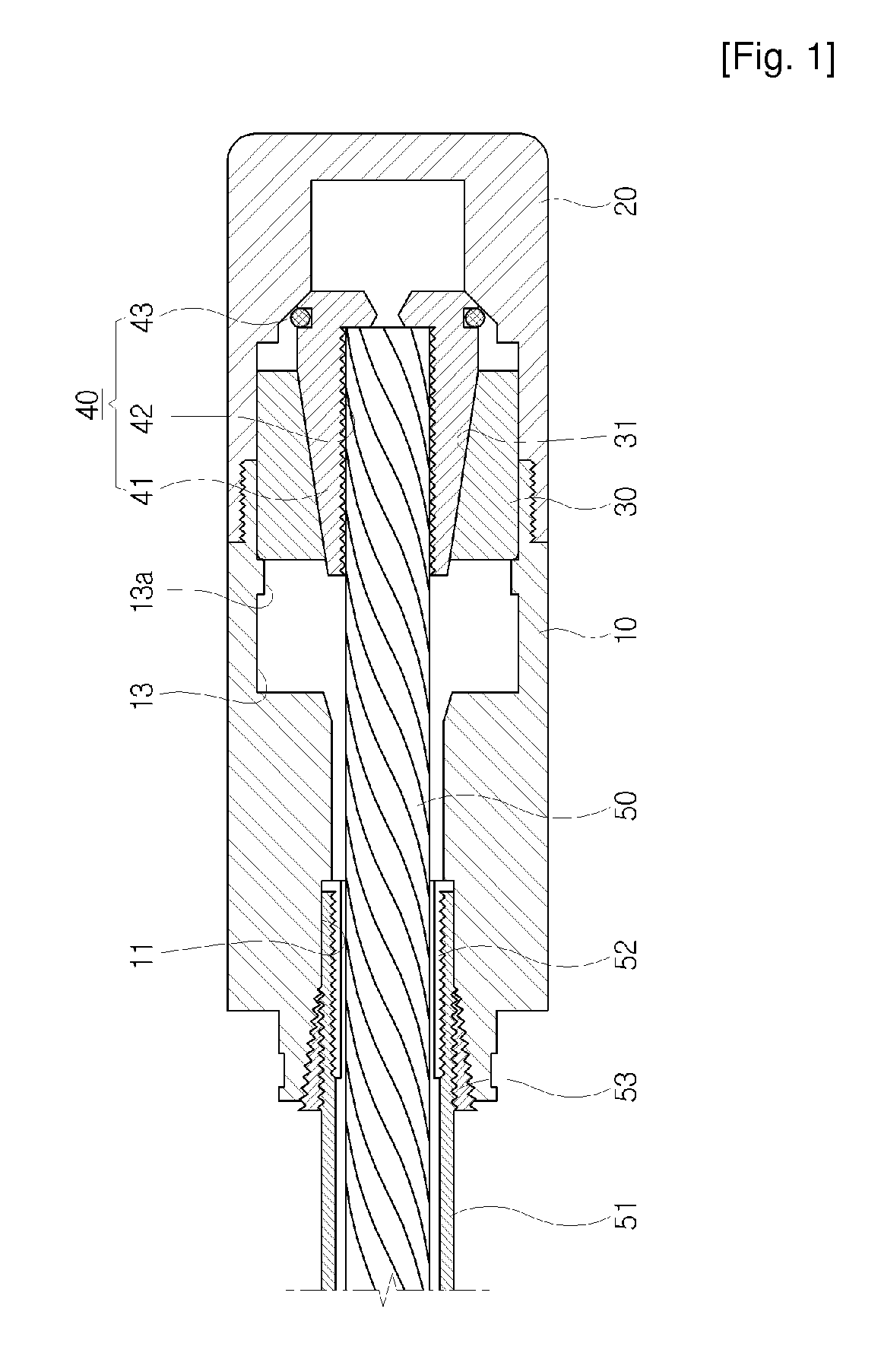

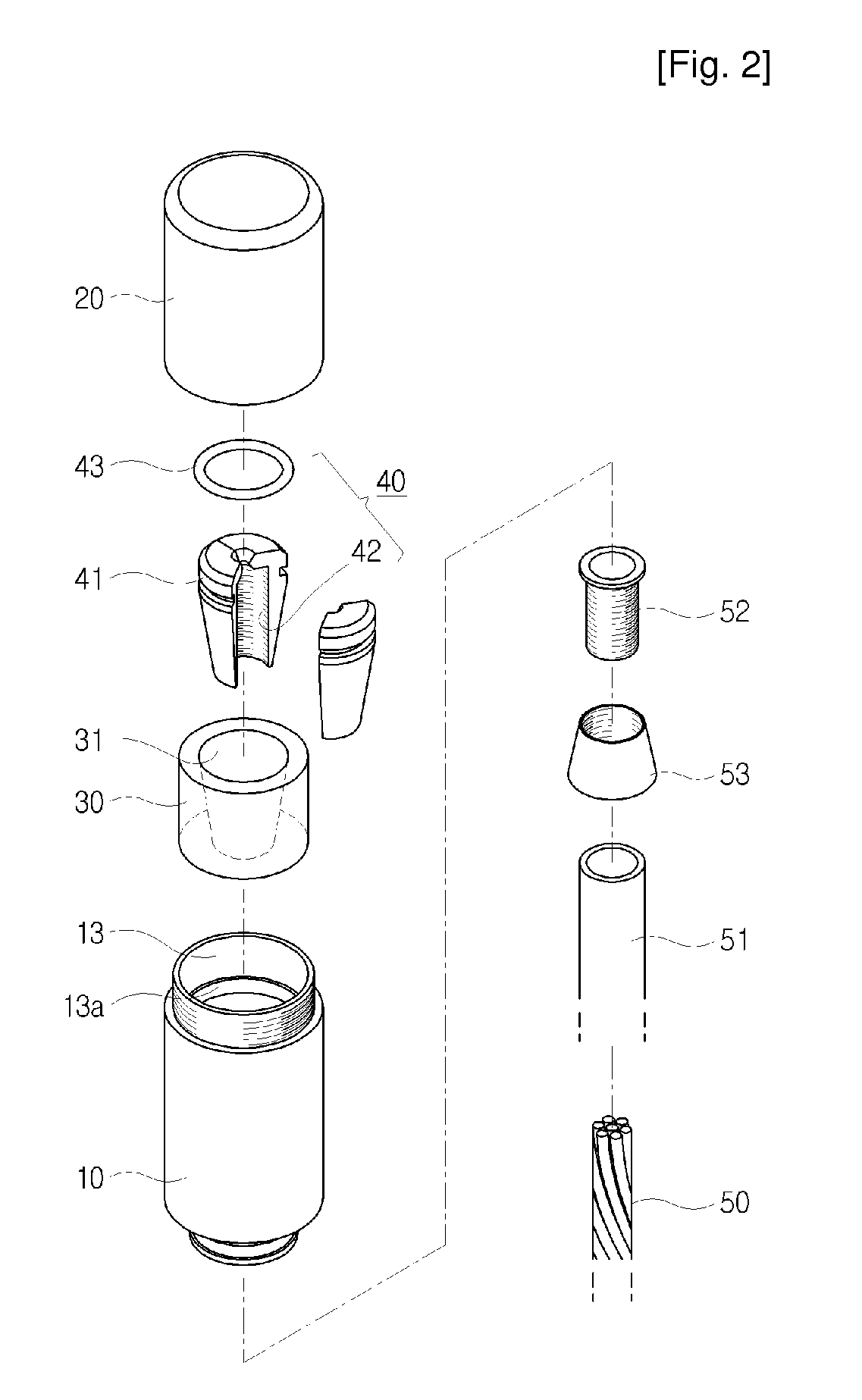

[0031]In order to accomplish the above objects, the present invention provides an internal fixer for an anchor having a releasable tensioning steel wire, including: a first outer body, with a tube coupling hole and a body seating hole coaxially formed in the first outer body so that the tensioning steel wire passes therethrough, and a wedge receiving body support means provided on an inner surface of the body seating hole; a wedge receiving body seated by the wedge receiving body support means in the body seating hole and having a conical wedge seating hole, into which separated wedge bodies are seated; a wedge unit seated into the wedge seating hole of the wedge receiving body and comprising the three separated wedge bodies, which are arranged in a cone shape to hold the tensioning steel wire; and a second outer body supporting and covering the wedge receiving body, which is seated in the body seating hole of the first outer body, and the wedge unit, which is placed in the wedge se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com