Hybrid Power Supply System

a hybrid power supply and power supply technology, applied in valve housings, process and machine control, instruments, etc., can solve the problems of increasing manufacturing costs and size, reducing the power efficiency of the conventional system to about 70%, and inconvenient and inefficient, so as to reduce the size of the hybrid power supply system, reduce the noise of the emi, and increase the power supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

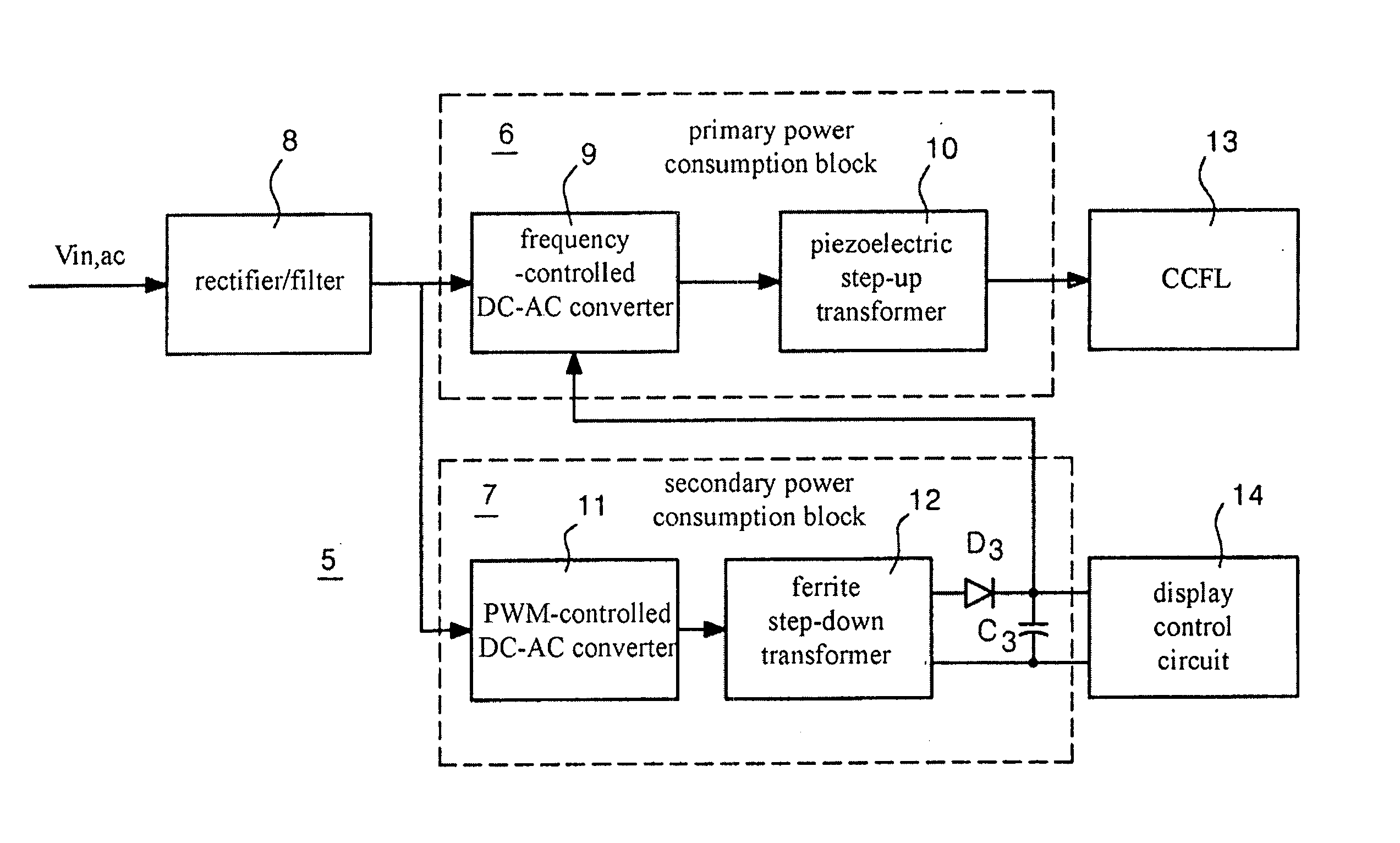

[0034]FIG. 6 is a circuit diagram of a first embodiment of the present invention.

[0035]In this embodiment, a sampler 22 and a comparator 23 are provided for automatic feedback control of the brightness of the CCFL 13. The sampler 22 generates a sampling voltage from an AC current of a CCFL 13 and the comparator 23 compares the sampling voltage with a predetermined reference voltage and generates a feedback output voltage. In this embodiment, a half-bridge MOSFET switch 17 is used as a frequency-controlled DC-AC converter 9.

[0036]First, an input voltage Vin is input to a rectifier / filter 8 including a filter 15 and a rectifier 16, through which the input voltage Vin is filtered and rectified. When the input voltage Vin is 90-132VAC, the rectifier / filter 8 outputs a DC voltage of 120-190VDC, and, when the input voltage Vin is 180-264VAC, it outputs a DC voltage of 250-380VDC.

[0037]The DC-AC converter 9 including the half-bridge MOSFET switch 17 converts the DC voltage output from the ...

embodiment 2

[0042]FIG. 7 is a circuit diagram of a second embodiment of the present invention.

[0043]In this embodiment, primary terminals of a piezoelectric step-up transformer 10 and a ferrite step-down transformer 12 are connected in parallel to an output terminal of a half-bridge MOSFET switch 17, so that DC-AC conversion is eliminated from a secondary power consumption block 7, thereby increasing the power supply efficiency. Since power consumption of each of a display control circuit 14, a VCO 19, and a comparator 23 is low, buck regulators 24 and 25 are used to reduce and stabilize a DC voltage that is input to these circuits.

[0044]An input terminal of the ferrite step-down transformer 12 is connected to an output terminal of the half-bridge MOSFET switch 17. An AC voltage stepped down by the ferrite step-down transformer 12 is converted to a DC voltage through a rectifier circuit D3 and C3. The DC voltage is further stepped down and stabilized through the buck regulator 25, and it is the...

embodiment 3

[0045]FIG. 3 is a circuit diagram of a third embodiment of the present invention.

[0046]In this embodiment, primary terminals of a piezoelectric step-up transformer 10 and a ferrite step-down transformer 12 are connected in series to an output terminal of a half-bridge MOSFET switch 17, so that DC-AC conversion is eliminated from a secondary power consumption block 7, thereby increasing the power supply efficiency. Similar to the second embodiment, since power consumption of each of a display control circuit 14, a VCO 19, and a comparator 23 is low, buck regulators 24 and 25 are used to reduce and stabilize a DC voltage that is input to these circuits.

[0047]Specifically, an input terminal of the ferrite step-down transformer 12 is connected between an output terminal of the half-bridge MOSFET switch 17 and an input terminal of the piezoelectric step-up transformer 10. Accordingly, this embodiment does not require the energy-saving inductance L1 provided in the first and second embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com