Solar panel system and method utilizing unframed solar panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

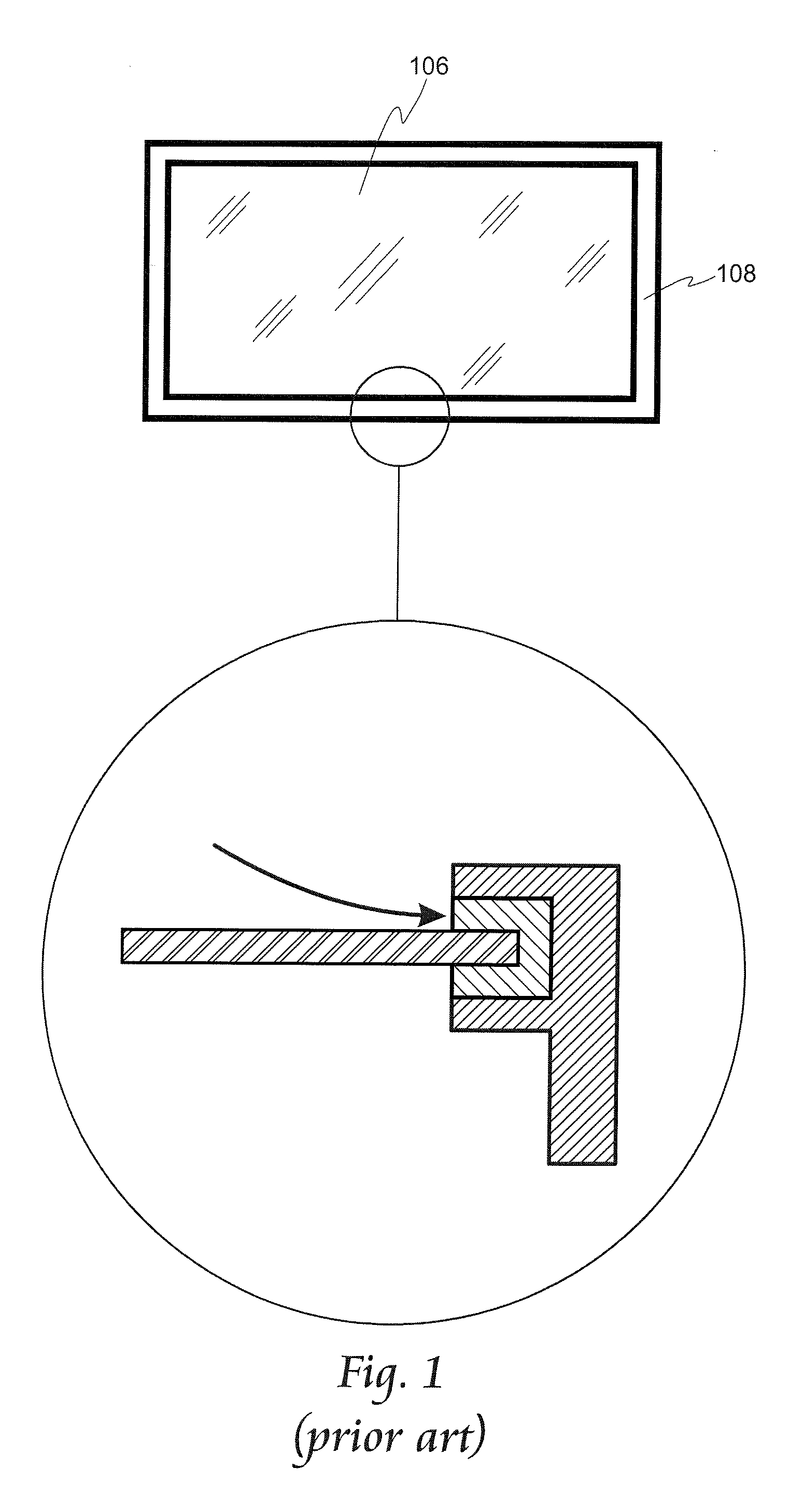

[0014]Referring first to FIGS. 1-2, an exemplary, ground-installed, prior art solar panel system 100 is illustrated. The prior art system 100 may comprise four vertical supports 102, two horizontal supports 104, each of which is coupled at each opposing end to a vertical support 102, and a plurality of solar panels 106 coupled to and positioned across the horizontal supports 104. Each solar panel 106 includes a frame 108 around an edge portion thereof.

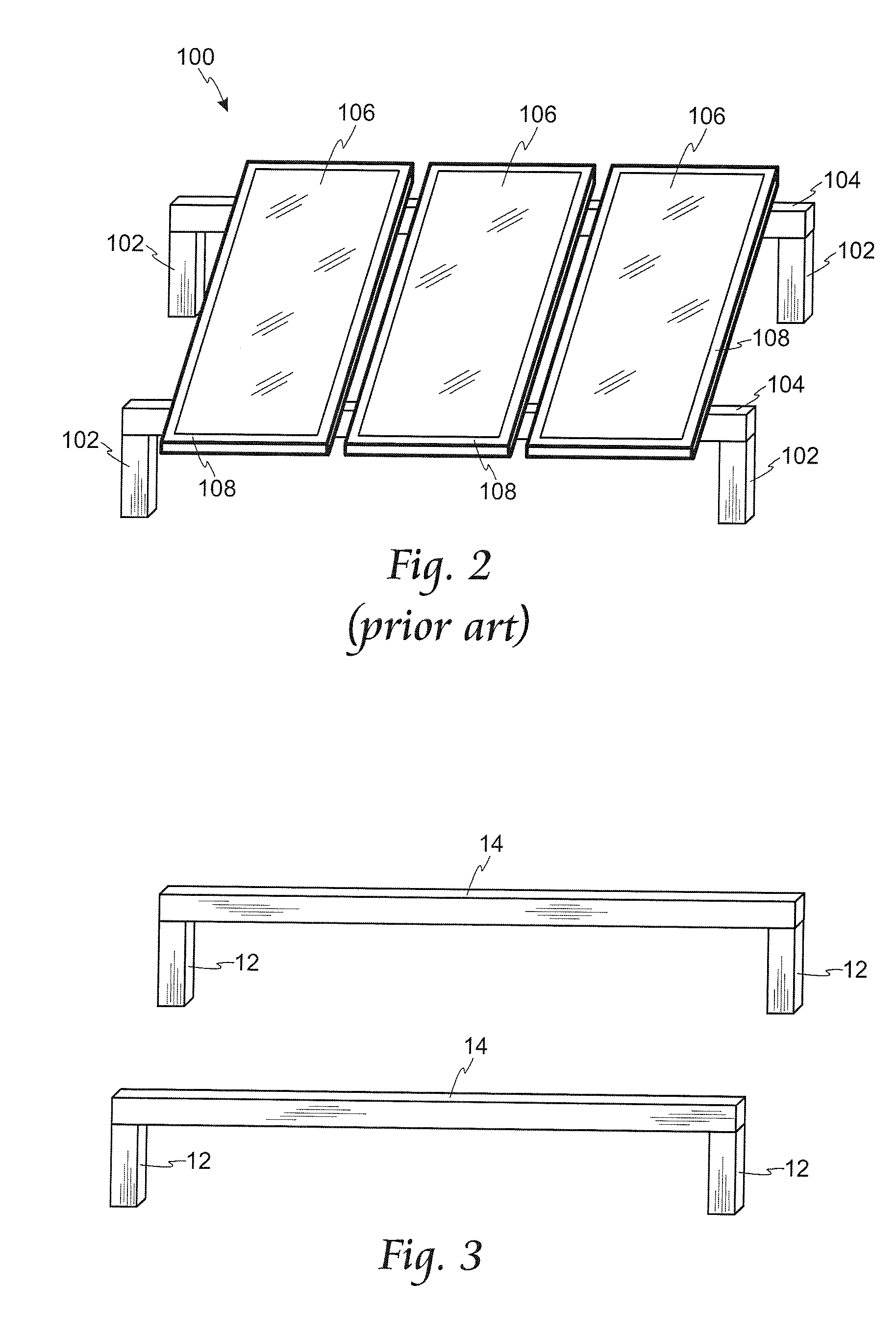

[0015]Referring now to FIGS. 3-5A, assembly of a solar panel system 10 consistent with an embodiment of the present invention is illustrated. The system 10 utilizes at least one and preferably a plurality of solar panels 16. Solar panels 16 are provided without framing therearound.

[0016]In one embodiment, assembly of a system 10 commences with installation of vertical supports 12, followed by the coupling thereto of horizontal supports 14 (see FIG. 3). Support beams 18 may then be coupled to the horizontal supports (see FIG. 4). The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com