Sealing material to metal bonding compositions and methods for bonding a sealing material to a metal surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

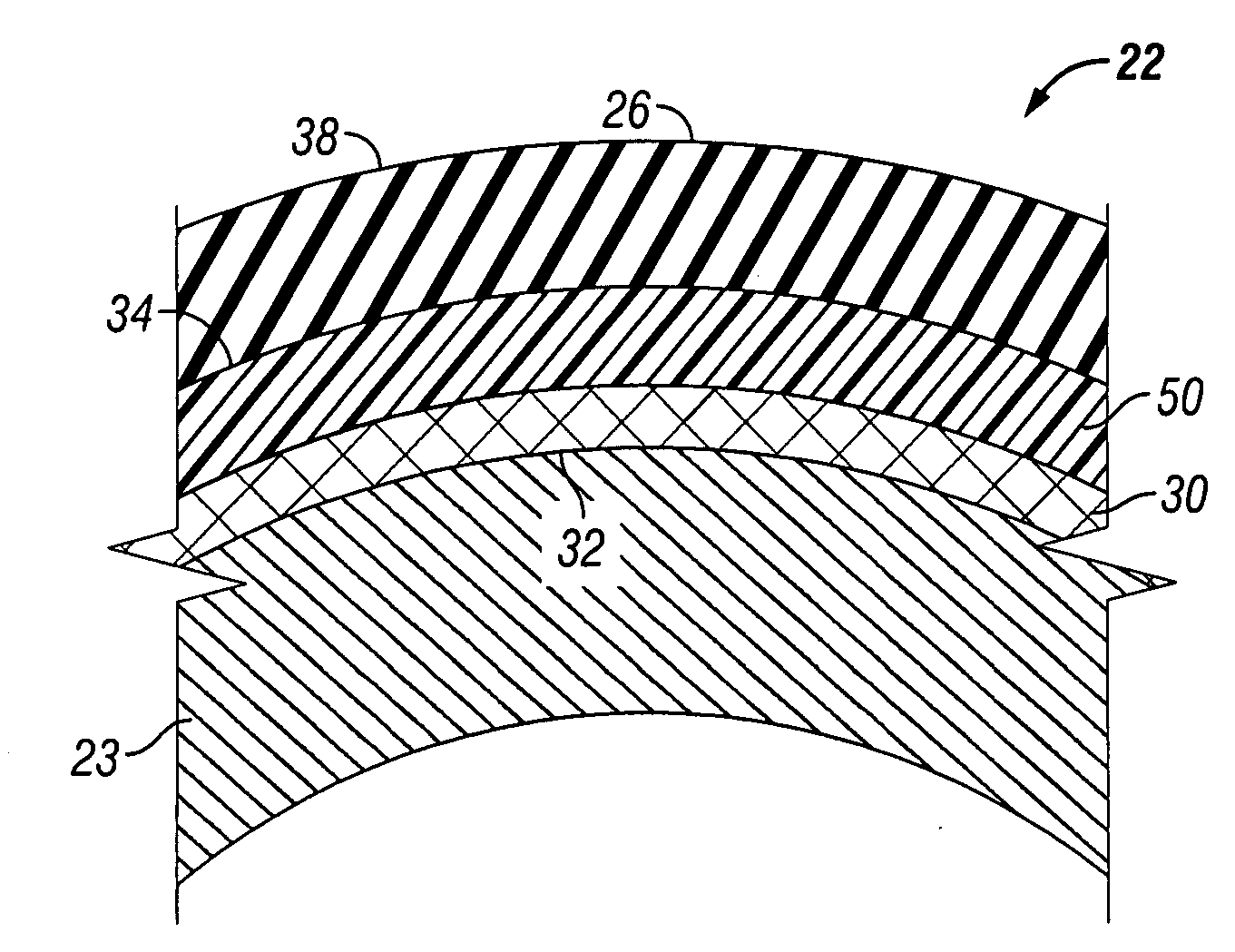

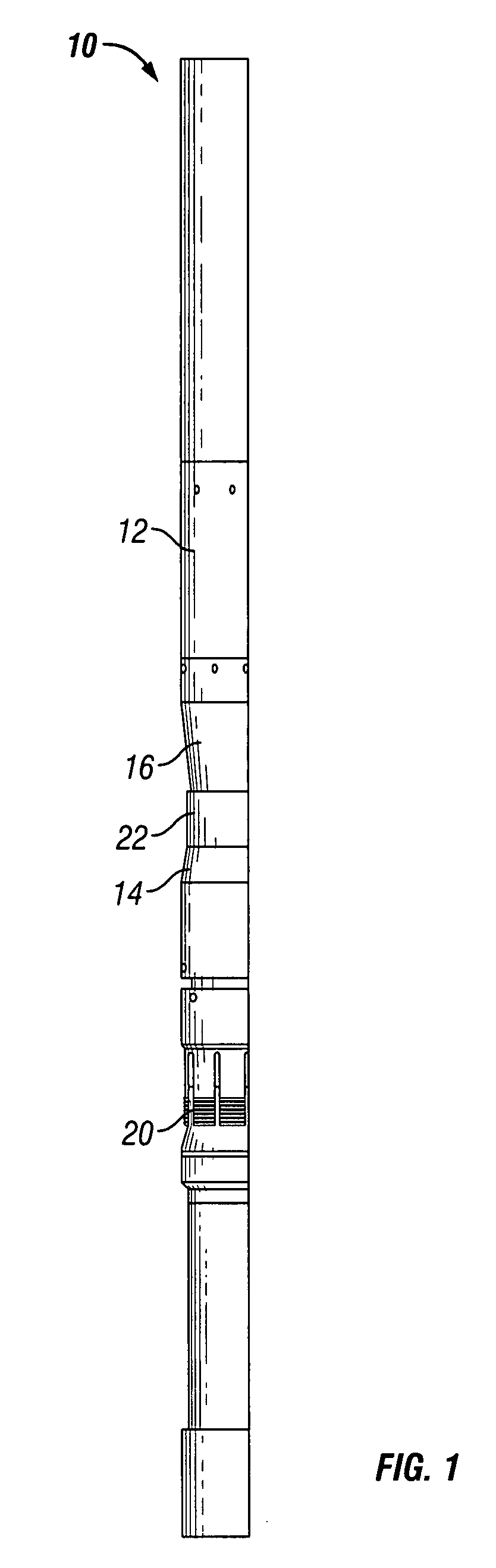

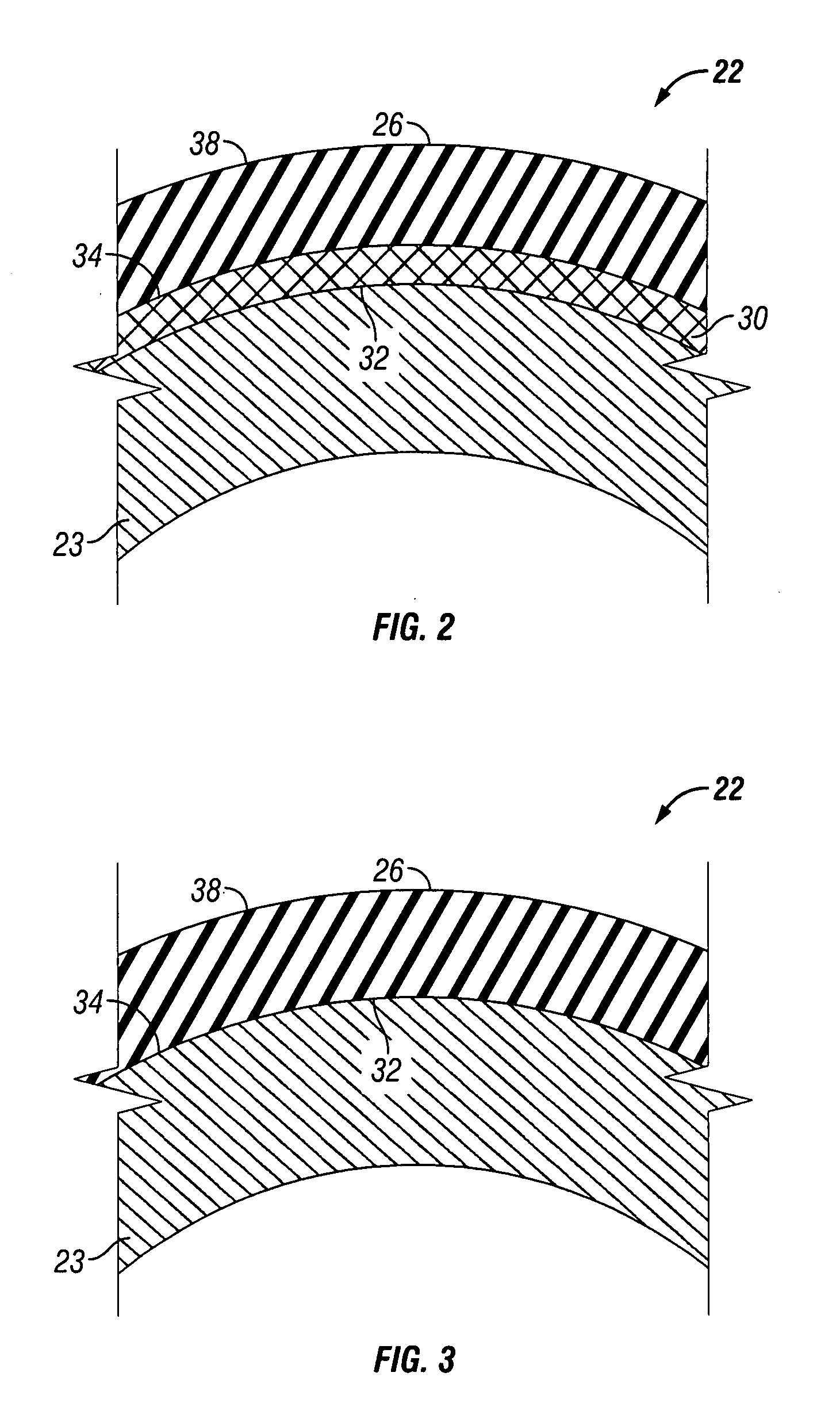

[0021]Referring now to FIG. 1, a downhole tool, such as a packer 10, includes a body or housing 12 and a sealing member or seal ring 22 disposed on the outer surface of housing 12 for sealing against a surrounding well casing. Housing 12 is generally cylindrical but may be any shape desired or necessary to form the downhole tool. An actuating member 14 is mounted to housing 12 for axial movement relative to housing 12. In this example, actuating member 14 engages a lower end of seal ring 22 for pushing seal ring 22 upward on a stationary cam surface 16 of housing 12 to cause seal ring 22 to expand radially into the set position. Cam surface 16 is preferably conical. Actuating member 14 may be an annular collet that is radially expansible, or it could be other configurations. In this embodiment, actuating member 14 is secured to a piston (not shown) supplied with hydraulic pressure for moving seal ring 22 relative to cam surface 16.

[0022]Tool 10 may be of a conventional design, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com