Adjustable heavy bag/speed bag frame with piston assist

a technology of piston assist and heavy bag, which is applied in the field of easy and efficient adjustment of frame with platform and structural members, can solve the problems of heavy and awkward control, and achieve the effect of easy control of the descent, heavy and awkward control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

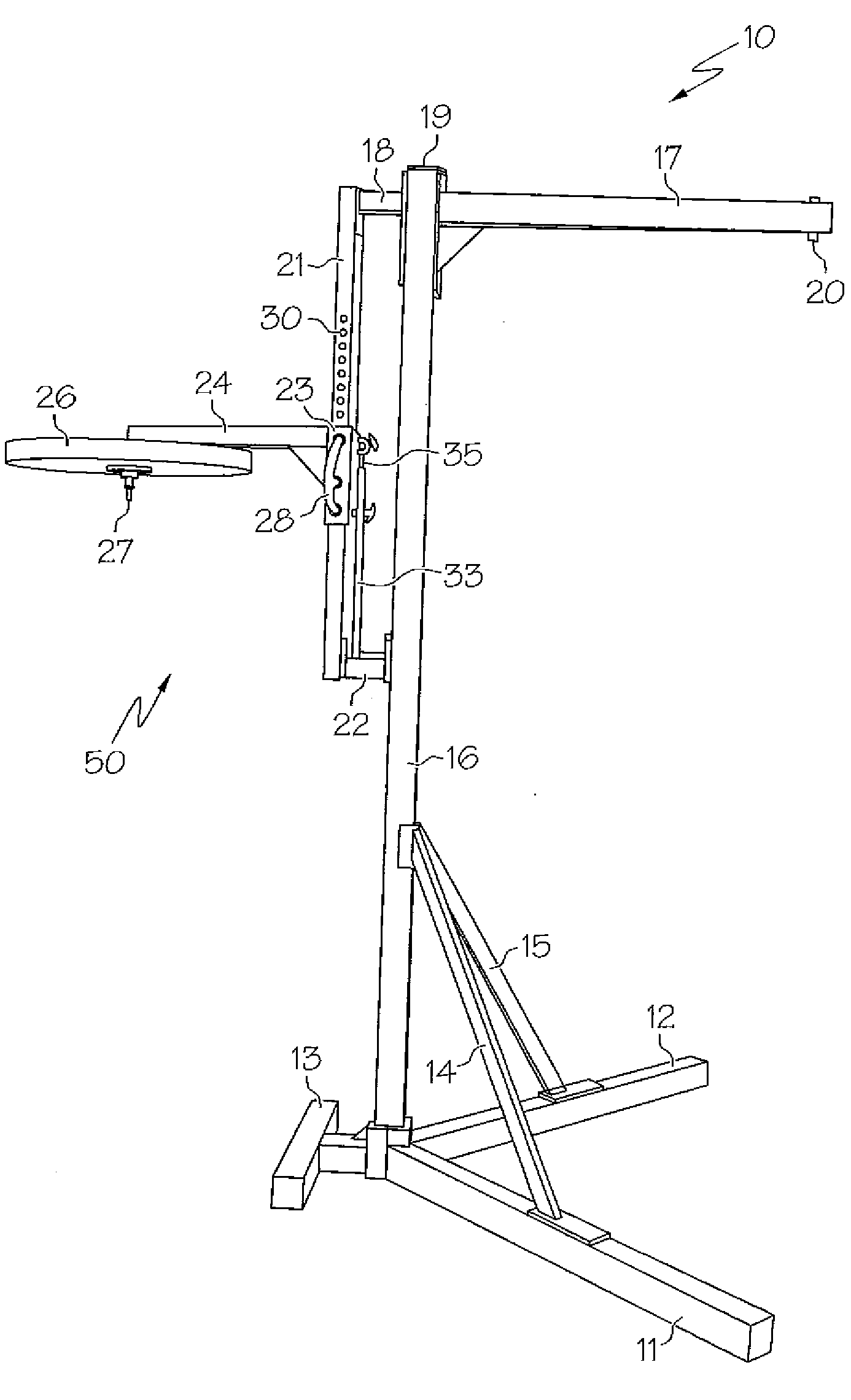

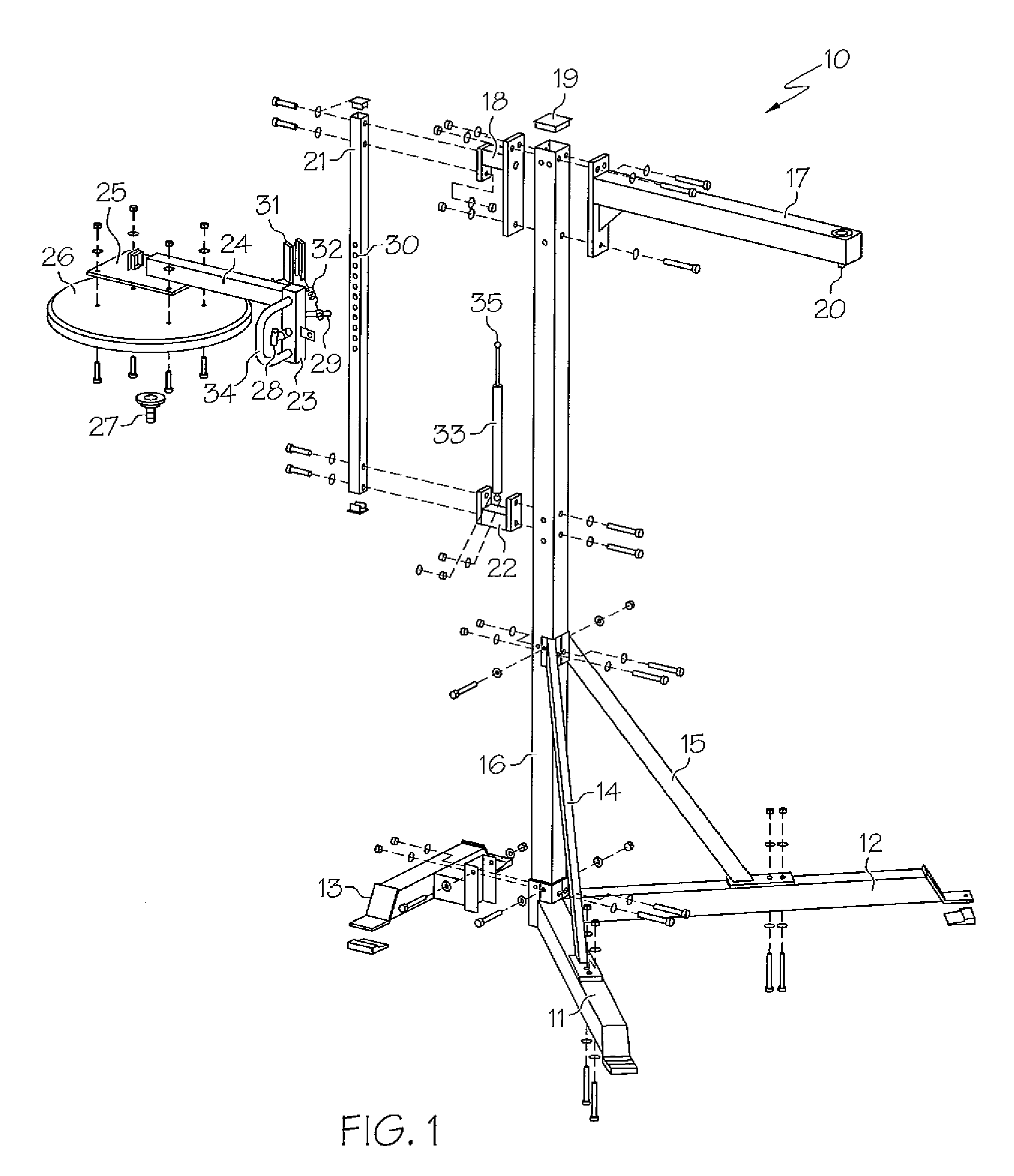

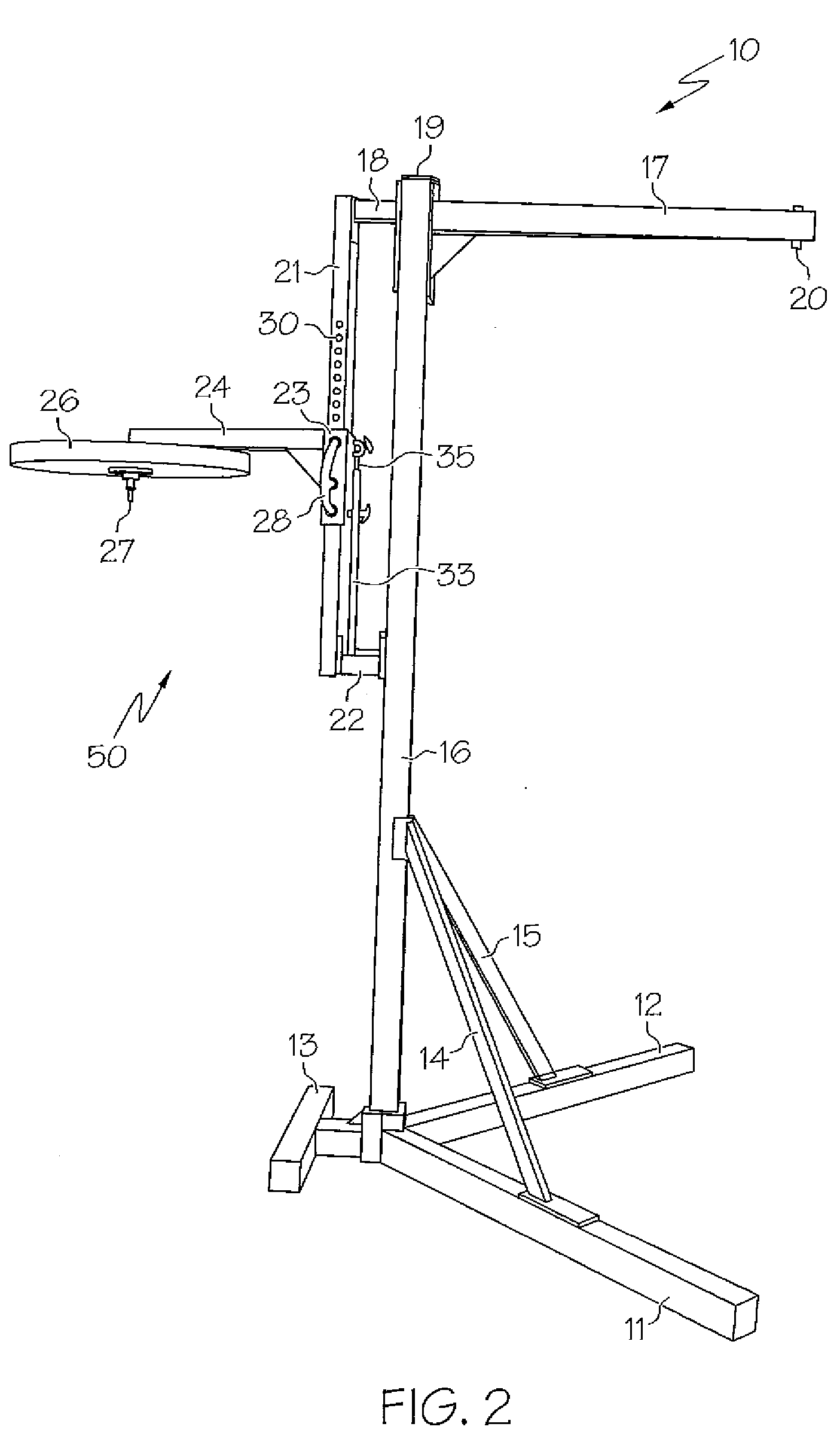

[0026]FIG. 1 illustrates an exploded view of the components of the preferred embodiment of the entire boxing frame 10, while FIG. 2 shows a side perspective view of the complete boxing frame 10. Referring to both FIGS. 1 and 2, the boxing frame consists of a main support piece 16 that extends vertically in a perpendicular direction to the surface upon which the boxing frame 10 rests upon. The main support piece 16 is constructed from any suitable high strength material that can be but is not limited to steel. The piece 16 is hollow to decrease the weight of the overall frame 10 and can be of any geometrical shape. In the preferred embodiment, the main support piece 16 is four sided to provide surfaces for the mounting of the additional components that make up the boxing frame 10.

[0027]A left and right base frame leg 12 and 11 and a base cross frame leg 13 are attached to the bottom of the main support member 16. The base legs 11, 12, and 13 limit the side to side displacement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com